Application range: The product is widely used in solid-liquid separation in petrochemical, nonferrou...

-

Chlor-alkali Chemical IndustryFilter presses are mainly used in the chloralkali industry to treat various wastewater and waste residues and separate and recover valuable substances.

-

Non-ferrous Metallurgical IndustryThe working principle of the filter press specially used for non-ferrous metal smelting is to separate the solid matter in the wastewater through high pressure to purify the wastewater.

-

Food And Pharmaceutical IndustryIn the pharmaceutical industry, filter presses are mainly used for filtering and separating drugs. Impurities and particulate matter in drugs can be effectively removed by filter presses, thus improving the quality and safety of drugs.

-

Fine ChemicalsIn the chemical industry, filter presses can separate fine chemical products, such as titanium dioxide, white carbon black, dyes, pigments, etc., to improve product quality and recovery rate.

-

Coal IndustryIn the coal industry, since coal particles are large and have a high moisture content, a filter press with a large filtration area and high filtration efficiency is required.

-

Municipal SewageMunicipal sludge filter press is mainly used for solid-liquid separation in the process of municipal sludge treatment, separating the water and solid in the sludge, to achieve the effect of volume reduction treatment.

-

New Energy IndustryThe filter press can separate and remove suspended matter, organic matter, heavy metals, and other substances in sewage, thereby achieving sewage purification and resource utilization.

-

Electroplating And Coating WastewaterIn the mining industry, filter presses are mainly used for tailings treatment and ore separation. Useful components in tailings can be recovered and utilized through filter presses, thus improving the utilization rate of mineral resources.

-

Steel IndustryThe filter press commonly used in steel mills is a device that uses filter material to block liquid and compress the filter cake to achieve solid-liquid separation. By compressing the filter cake, the moisture in the filter cake is squeezed out, thus achieving the separation effect.

-

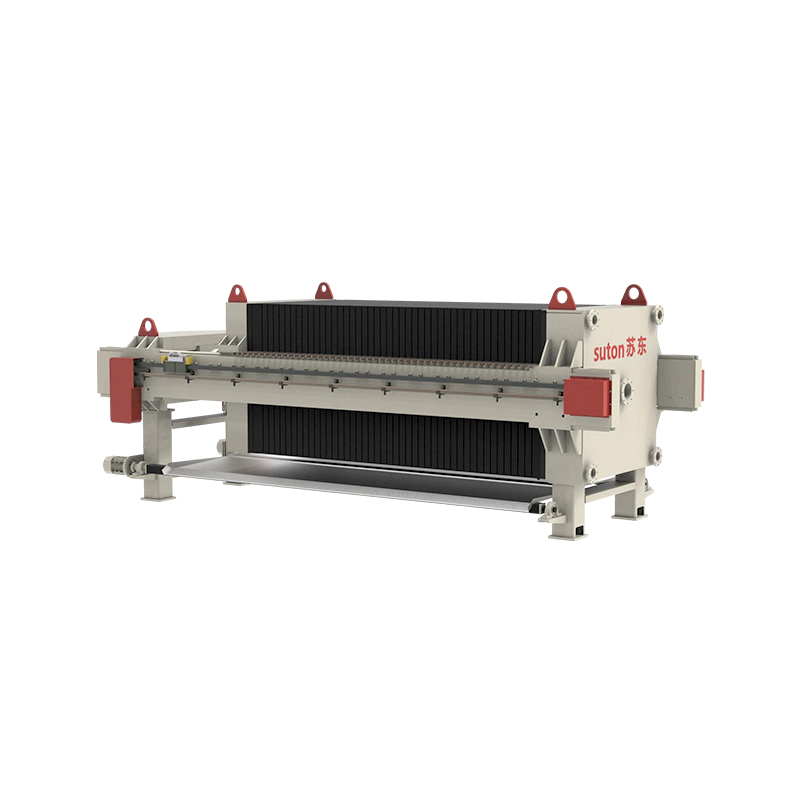

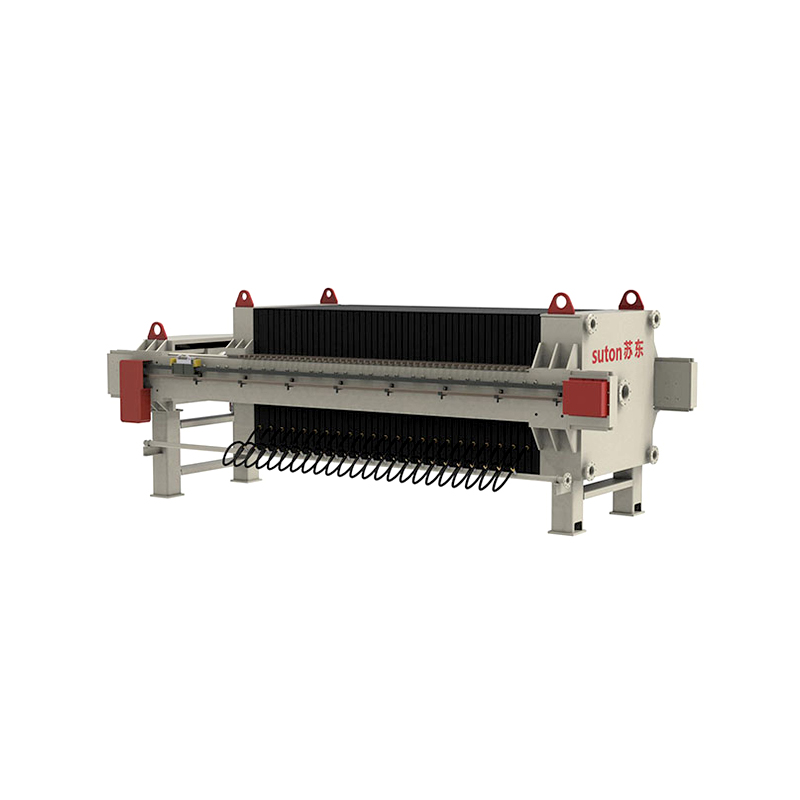

Polypropylene plate diaphragm filter pressView More

Polypropylene plate diaphragm filter pressView MoreApplication range: The products are widely used in industries with high requirements for solid-liqui...

-

Composite rubber plate chamber filter pressView More

Composite rubber plate chamber filter pressView MoreApplication range: The product is widely used in solid-liquid separation in petrochemical, non-ferro...

-

Composite rubber plate diaphragm filter pressView More

Composite rubber plate diaphragm filter pressView MoreApplication range: The product is widely used in solid-liquid separation in petrochemical, non-ferro...

-

Automatic Filter press with cloths dischargeView More

Automatic Filter press with cloths dischargeView MoreApplication range: The products are widely used in solid-liquid separation in petrochemical, non-fer...

-

Automatic Efficient Water Washing Filter PressView More

Automatic Efficient Water Washing Filter PressView MoreApplication range: The product is widely used in solid-liquid separation with high viscosity and dif...

-

Fully automatic vibration filter pressView More

Fully automatic vibration filter pressView MoreProduct features: The fully automated control system of the equipment covers multiple links such as ...

-

Quick Opening Filter PressView More

Quick Opening Filter PressView MoreApplication range: The product is widely used in solid-liquid separation in petrochemical, nonferrou...

-

Programmable filter press conveying integrated machineView More

Programmable filter press conveying integrated machineView MoreApplication range: The product is widely used in the solid-liquid separation process in industrial p...

-

Vehicle-mounted mobile filter pressView More

Vehicle-mounted mobile filter pressView MoreApplication range: The product is widely used in sewage treatment, construction engineering, river d...

-

Integrated sewage treatment deviceView More

Integrated sewage treatment deviceView MoreProduct features: The high-efficiency and high-pressure sewage treatment integrated system device is...

-

Polypropylene filter plateView More

Polypropylene filter plateView MoreProduct features: The polypropylene filter plate is reinforced and modified with TPE elastomer and a...

-

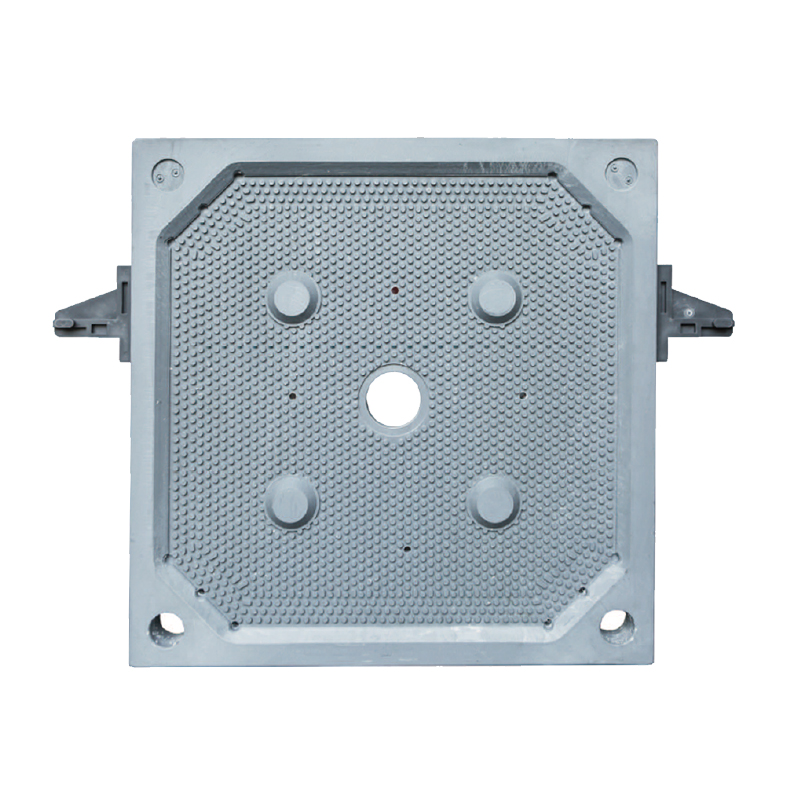

Polypropylene diaphragm filter plateView More

Polypropylene diaphragm filter plateView MoreProduct features: The diaphragm filter plate of the Sudong filter press is a comprehensive design ba...

-

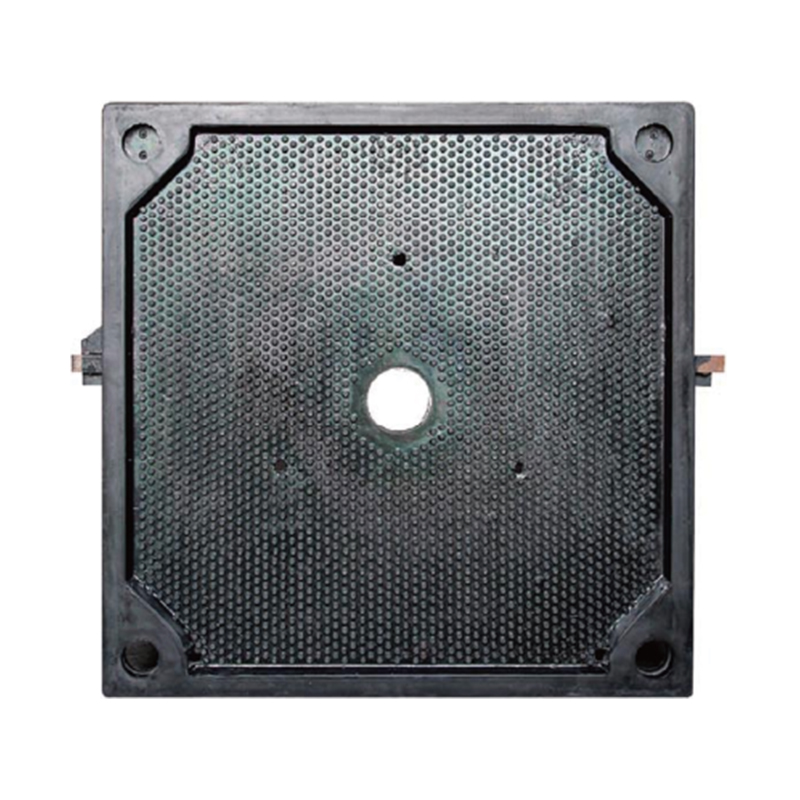

Composite rubber filter plateView More

Composite rubber filter plateView MoreProduct features: Our rubber sheet series products have independent intellectual property rights and...

-

Composite rubber diaphragm plateView More

Composite rubber diaphragm plateView MoreProduct features: The rubber diaphragm filter plate is a new type of diaphragm series product develo...

-

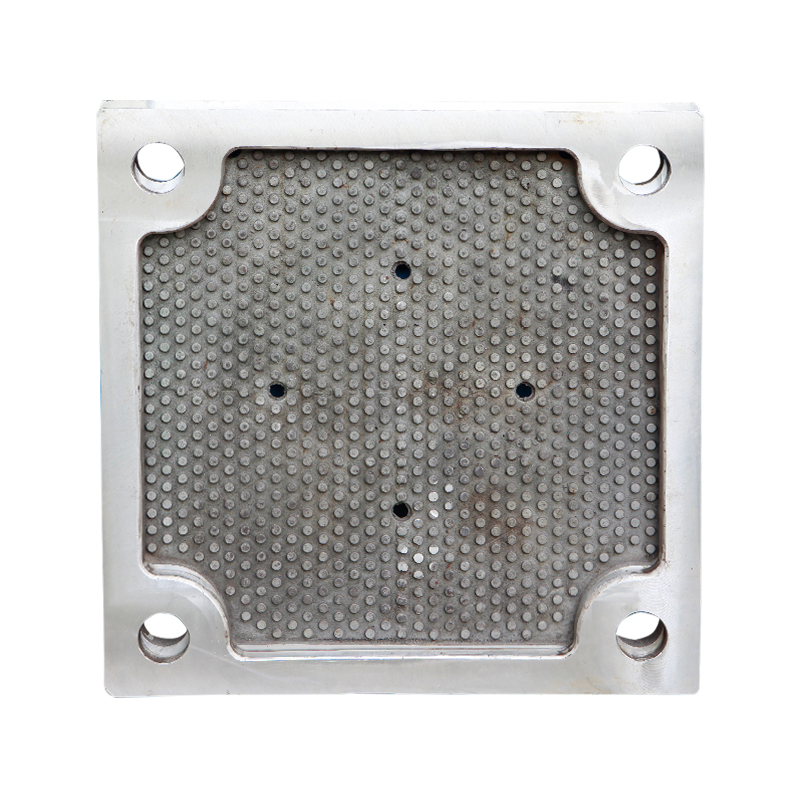

Stainless steel filter plateView More

Stainless steel filter plateView MoreApplication range: The product has good hygienic performance and is suitable for industries with hig...

-

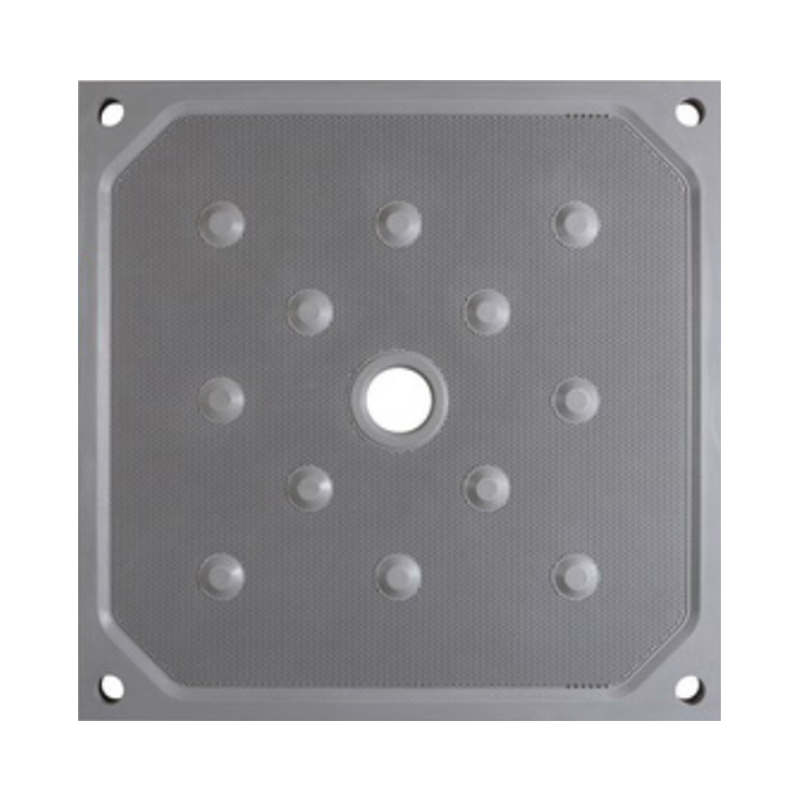

High Pressure Diaphragm Filter PlateView More

High Pressure Diaphragm Filter PlateView MoreHigh-pressure diaphragm filter plate consists of two diaphragms and core plate, through the external...

-

Reinforced Polypropylene Filter PlateView More

Reinforced Polypropylene Filter PlateView MoreReinforced polypropylene filter plate is moulded by patented technology, high temperature resistant,...

-

Mud storage hopperView More

Mud storage hopperView MoreApplication scenario: The filter press mud hopper is a supporting component of the filter press. It ...

-

Screw conveyorView More

Screw conveyorView MoreProduct features: The screw conveyor is a common conveying equipment. It is mainly composed of a spi...

-

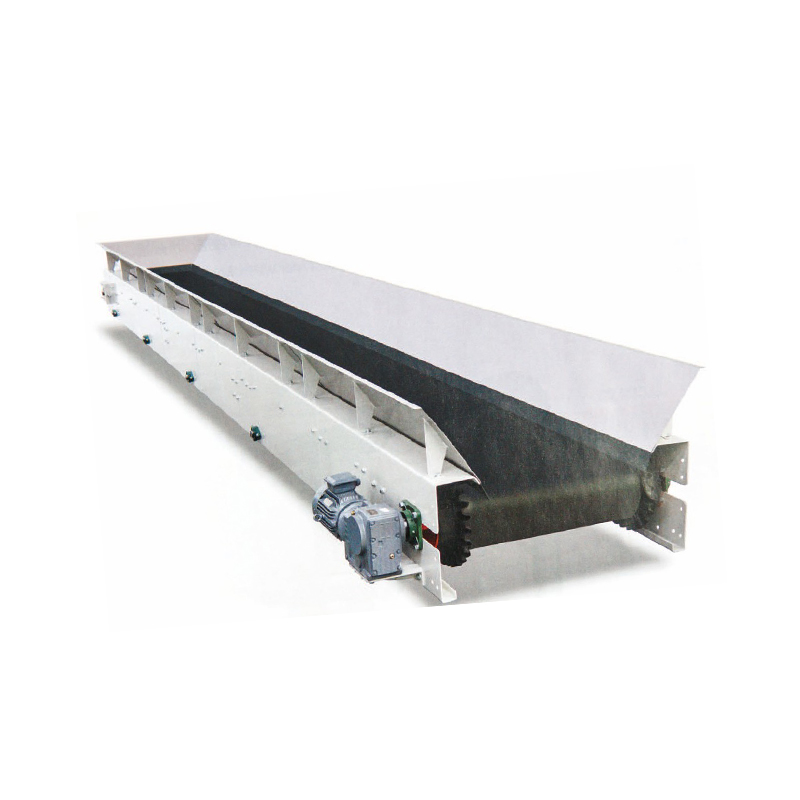

Belt conveyorView More

Belt conveyorView MoreApplication range: Belt conveyors can be divided into heavy-duty belt conveyors and light-duty belt ...

-

Pharmaceutical preparation deviceView More

Pharmaceutical preparation deviceView MoreApplication range: The product is widely used in water treatment, sewage treatment, chemical industr...

-

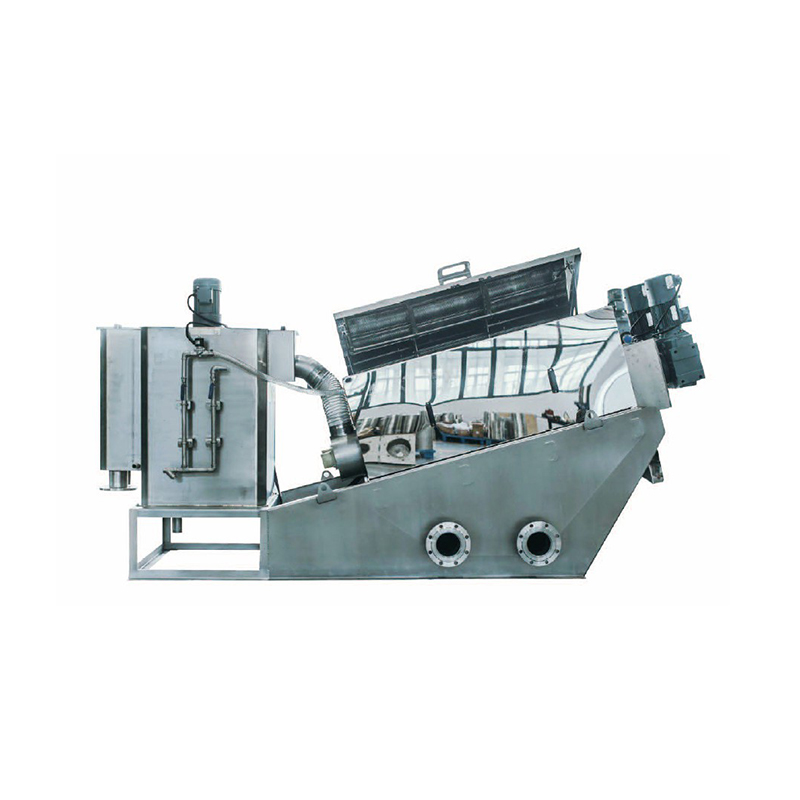

Screw stack sludge dewatering machineView More

Screw stack sludge dewatering machineView MoreApplication range: The spiral stacking sludge dewatering machine is suitable for sludge treatment in...

China filtration equipment manufacturer and custom filter press factory

, and was founded in June 1956. It is an environmental protection technology enterprise integrating filter press technology research and development, complete filtration equipment manufacturing, and environmental protection project contracting. Specializing in the design and manufacture of filter presses for more than 30 years, it is a well-known professional enterprise in the manufacture of various types of filter presses in China.-

0+

Years Of Experience

-

0+

Configure Signals

-

0+

Patented Invention

-

OEM/ODM Customization

We have a strong R&D team and can customize products according to customer requirements and working conditions.

-

Cost Of Production

We have our own processing factory, factory direct sales, high quality and low price.

-

Product Quality

90% of our products are produced by our company, including racks, filter plates, filter cloths, cylinders, hydraulic stations, and other components to ensure product quality.

-

Annual Output

Our annual output exceeds 1,000 filter presses, which can meet the needs of customers with different purchasing volumes.

-

Excellent Service

We focus on high-end markets, our products meet international standards and are mainly exported to Europe, America, Australia, Canada, Southeast Asia, India and other countries.

-

Cargo Freight

We are only 160 kilometers away from Shanghai Port, and export is very convenient.

-

How to Maintain and Troubleshoot a Filter Press for Optimal Performance?View More

Filter presses are essential machines in industries such as wastewater treatment, mining, food processing, and chemicals. They are designed to separate solids from liquids, ensuring efficient filtration and a higher quality of the filtered liquid. 1. Regular Cleaning and Inspection Why It’s Importan...

-

What Are the Common Problems with Filter Press Plates and How to Fix Them?View More

Filter press plates are critical components used in various industrial applications such as wastewater treatment, chemical processing, and food industries. They are responsible for separating solid particles from liquids by creating a pressure-driven filtration process. 1. Plate Leakage Problem: Lea...

-

How Do You Clean and Maintain Filter Press Cloth for Maximum Efficiency?View More

Proper cleaning and maintenance of filter press cloths are crucial for ensuring optimal filtration performance, reducing operational downtime, and extending the life of the filter press. 1. Regular Inspection and Pre-Cleaning Check Before beginning the cleaning process, it’s essential to conduct a t...

-

What Is a Diaphragm Filter Press and How Does It Work?View More

A Diaphragm Filter Press is an advanced type of filtration equipment designed to separate solid particles from liquids in various industrial applications. It utilizes a unique diaphragm at the rear of each filter plate, which improves the dewatering process by applying extra pressure to the solid ca...

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt