As China Composite rubber diaphragm plate Manufacturers and Composite rubber diaphragm plate Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

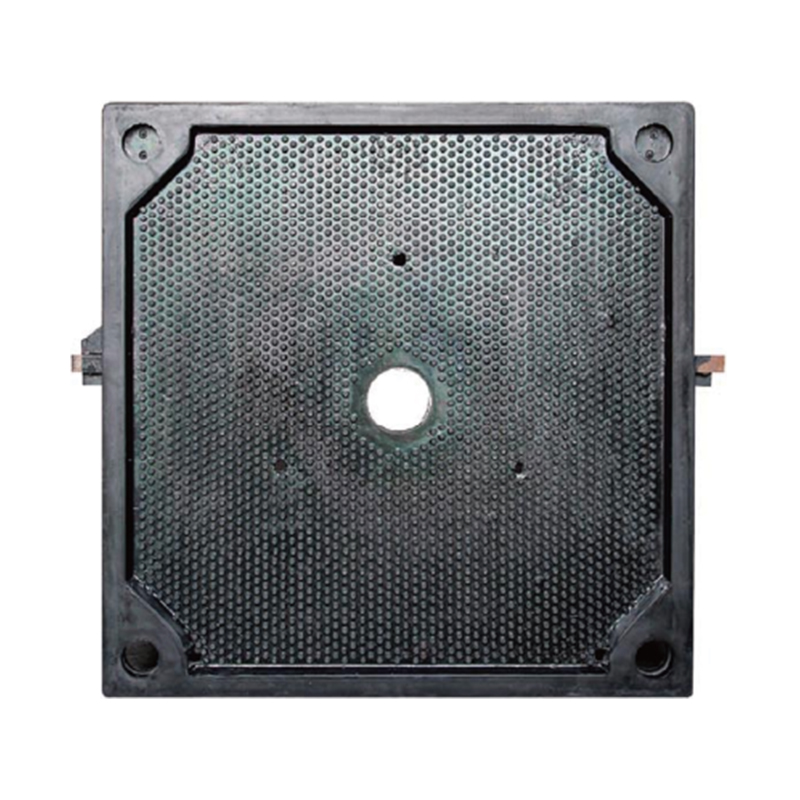

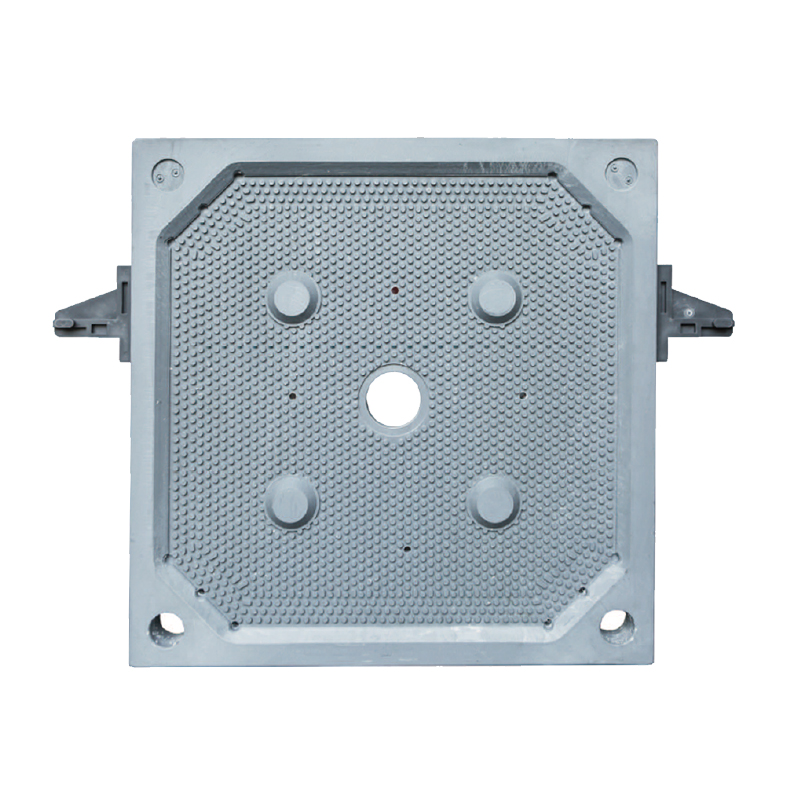

Composite rubber diaphragm plate

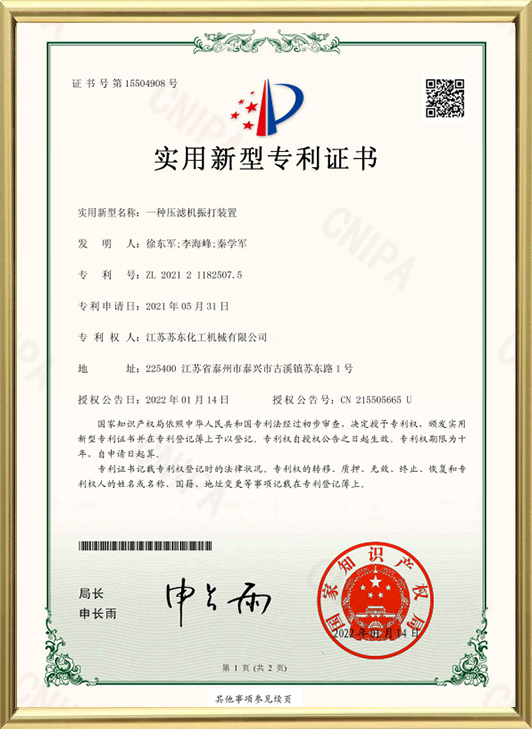

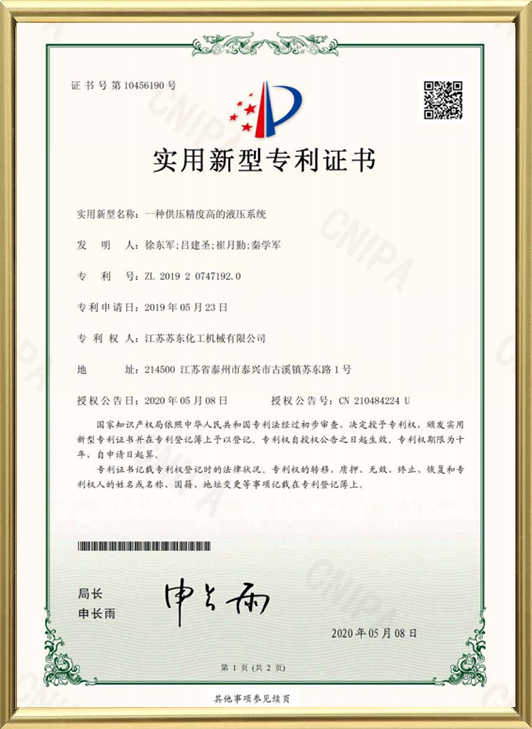

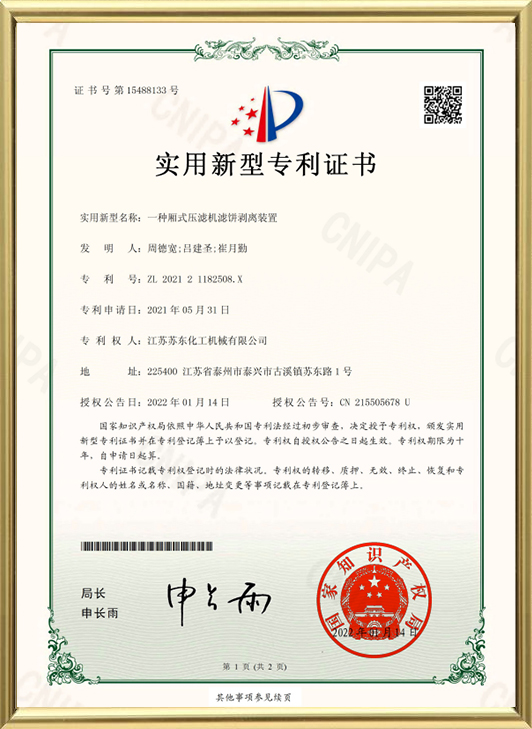

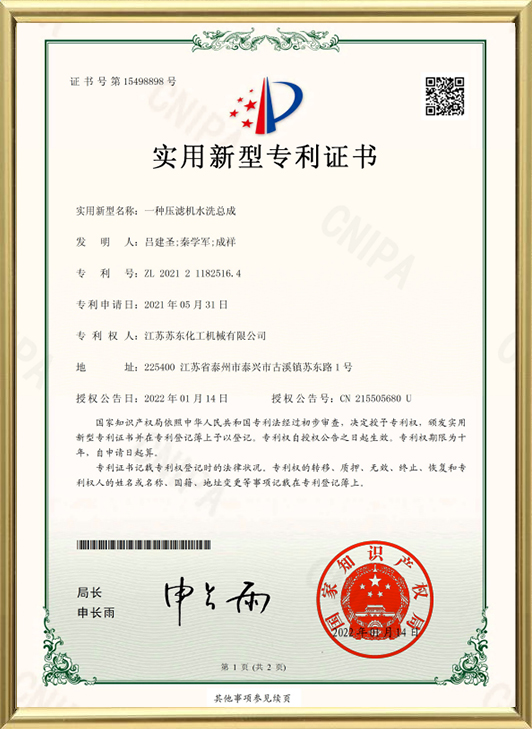

Product features: The rubber diaphragm filter plate is a new type of diaphragm series product developed by our company, with independent intellectual property rights and national patents.

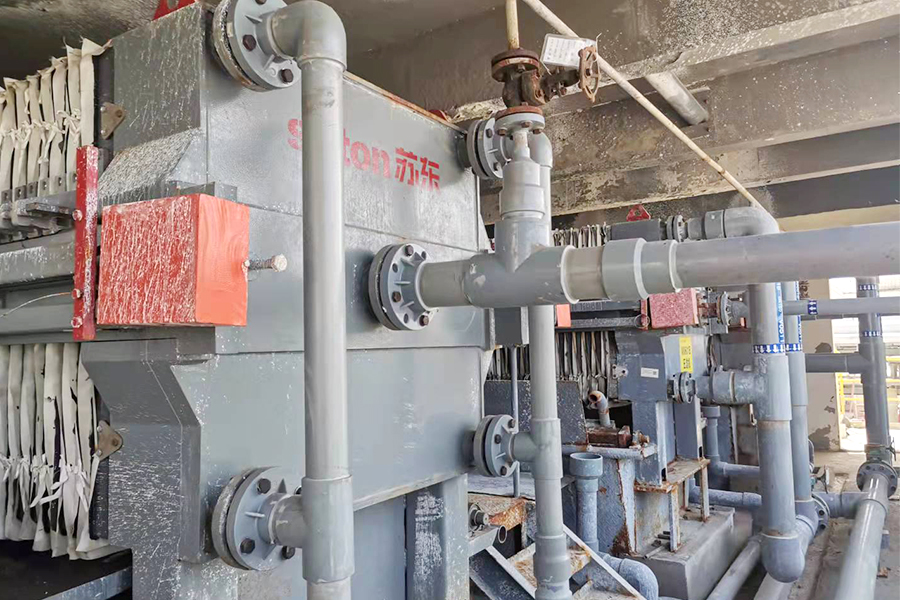

Product advantages: The filter plate is made of high-quality chloroprene rubber raw material, which is mixed and modified and then composite vulcanized with a steel frame under high pressure to form an integrated unit. It inherits the sealing performance of the composite rubber plate and takes into account the squeezing performance of the polypropylene diaphragm plate. It has a wider range of uses and better filtering effects. It has a large processing capacity and a low moisture content in the filter cake. The single-sided pressure of the filter plate is 0.6-1.2MPa, and the diaphragm tympanic pressure can reach 1.6MPa. The steel frame can be recycled and re-rubberized many times, and the comprehensive economic benefits are high.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

What is the role of the core plate in the Composite Rubber Diaphragm Plate?

Jiangsu Sudong Chemical Machinery Co., Ltd. is a Chinese filtration equipment manufacturer that has always been at the forefront of technological innovation and is committed to providing efficient and reliable filtration solutions to customers around the world. Composite Rubber Diaphragm Plate is one of our products. It has a unique design and excellent performance and has won wide acclaim in the industry.

With the rapid development of industrialization, environmental protection issues have become increasingly prominent, and the requirements for solid-liquid separation technology have become increasingly higher. Traditional filtration equipment often has problems such as low filtration efficiency, high water content in filter cakes, and high maintenance costs, which are difficult to meet the needs of modern industrial production. With years of technical accumulation and keen market insight, Sudong Chemical has successfully developed a new type of filtration element, the composite rubber diaphragm plate. It inherits the sealing performance of traditional rubber plates and incorporates the extrusion performance of polypropylene diaphragm plates, achieving a double improvement in filtration efficiency and filtration effect.

1. In the complex and sophisticated system of the composite rubber diaphragm plate, the core plate is undoubtedly the soul. It is the supporting skeleton of the entire filter plate structure, and it is also the key factor to achieve efficient filtration and stable operation. The following is the specific role of the core plate in the composite rubber diaphragm plate.

Enhance structural strength and stability: The core plate is usually made of high-strength, corrosion-resistant metal materials, such as stainless steel or alloy steel. These materials have excellent mechanical properties and chemical stability, and can withstand the huge pressure and impact generated during the filtration process. The existence of the core plate enables the composite rubber diaphragm plate to maintain a stable shape and size under high pressure, effectively preventing the deformation and damage of the filter plate. At the same time, it also enhances the overall rigidity and durability of the filter plate and extends the service life of the equipment.

2. The design of the core plate fully considers the distribution law of the fluid in the filter chamber. Through reasonable flow channel design and the arrangement of distribution holes, the core plate can guide the fluid to pass through filter media such as filter cloth or filter paper more evenly, reducing dead corners and short circuits during the filtration process. This improves the filtration efficiency and ensures the uniformity and consistency of the filtration effect. In addition, the core plate can also perform preliminary pretreatment and distribution of the fluid to create good conditions for the subsequent filtration process.

3. During the squeezing stage, the core plate works with the rubber diaphragm to achieve effective squeezing of the filter cake. The core plate provides solid support and positioning for the rubber diaphragm, ensuring stability and consistency during the squeezing process. At the same time, it can also evenly transfer external pressure to the rubber diaphragm and filter cake, so that the moisture and residual liquid in the filter cake can be discharged more thoroughly. This reduces the water content and volume of the filter cake and improves the quality and purity of the filter cake. In Sudong Chemical's composite rubber diaphragm plate, the perfect combination of the core plate and the rubber diaphragm makes the squeezing effect more significant, further improving the filtration efficiency and economic benefits.

4. Although the core plate plays a vital role in the composite rubber diaphragm plate, its design also fully considers the convenience of maintenance and replacement. The core plate is usually modularly designed, which can be easily disassembled and replaced with the rubber diaphragm and other components. This reduces maintenance costs and time costs, and also improves the maintainability and reliability of the equipment. When the filter plate is worn or damaged, users can easily replace the new core plate and rubber diaphragm to ensure the continued stable operation of the equipment.

As a key component of the composite rubber diaphragm plate, the core plate plays an irreplaceable role in enhancing structural strength, optimizing fluid distribution, improving squeezing effect, and facilitating maintenance and replacement. Jiangsu Sudong Chemical Machinery Co., Ltd. has successfully developed this composite rubber diaphragm plate product with independent intellectual property rights by relying on its deep accumulation in the field of filter press technology and its spirit of continuous innovation. It solves the problems existing in traditional filtering equipment and provides users with more efficient, reliable and economical filtering solutions. In the future, Sudong Chemical will continue to uphold the business philosophy of "scientific and technological innovation, quality first, and customer first", and continue to launch more high-quality products and services to contribute to the development of global environmental protection.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt