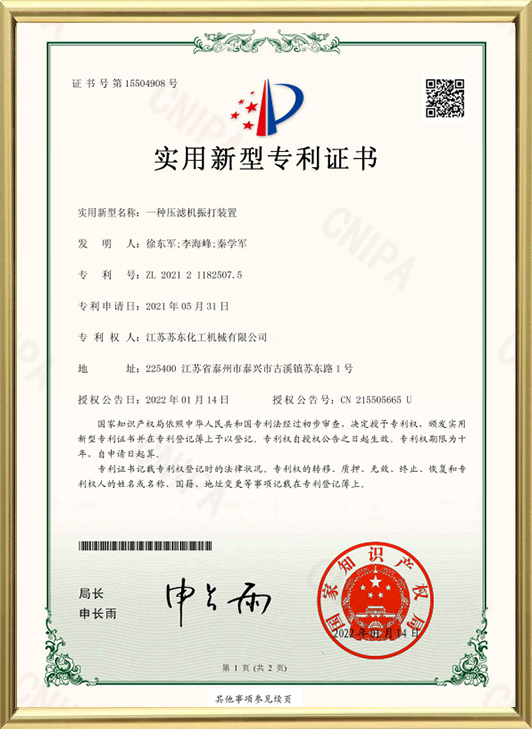

As China Composite rubber filter plate Manufacturers and Composite rubber filter plate Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

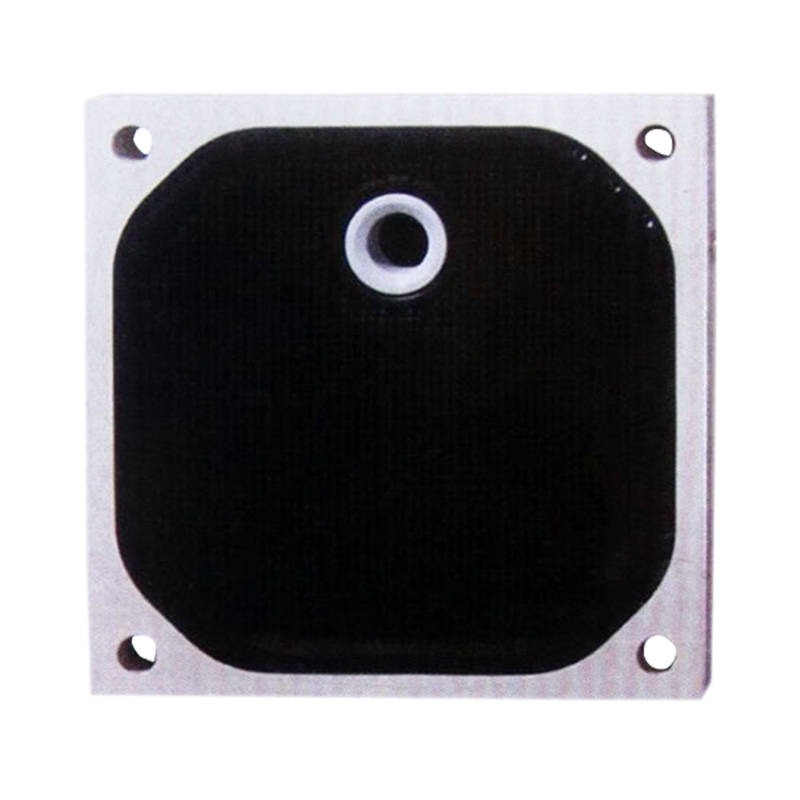

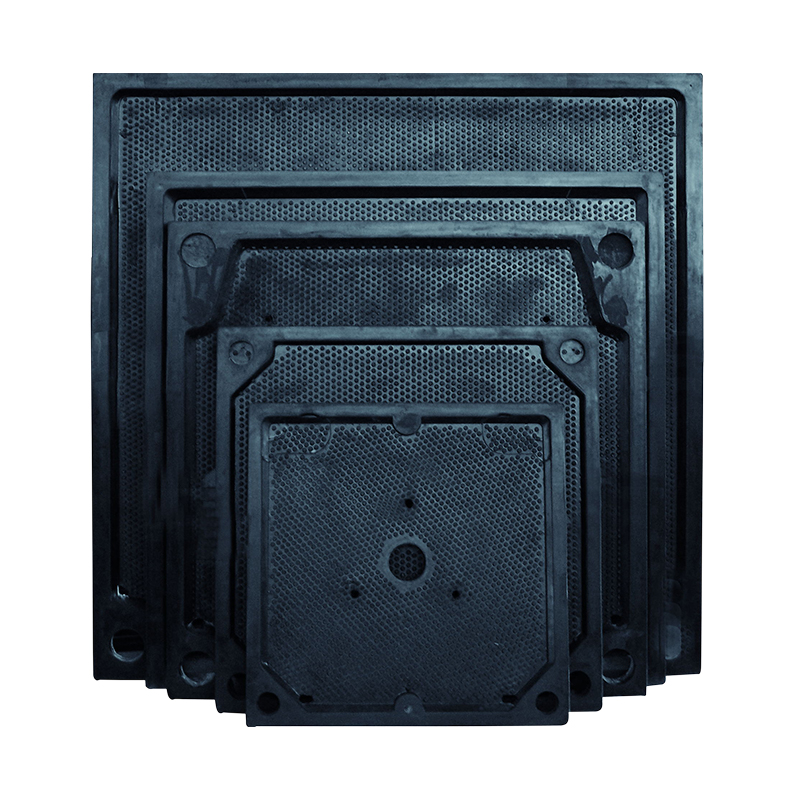

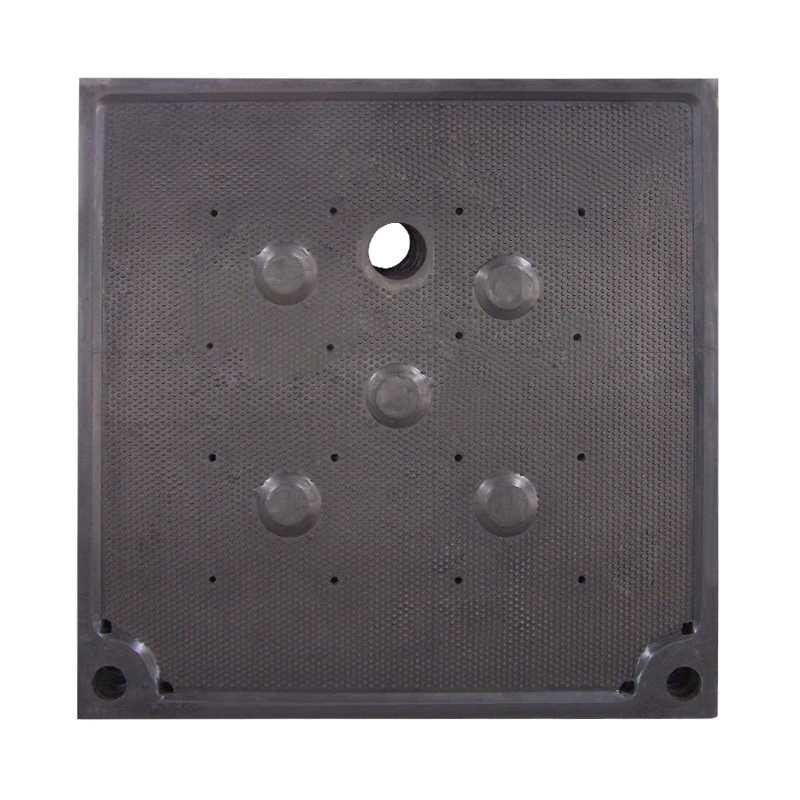

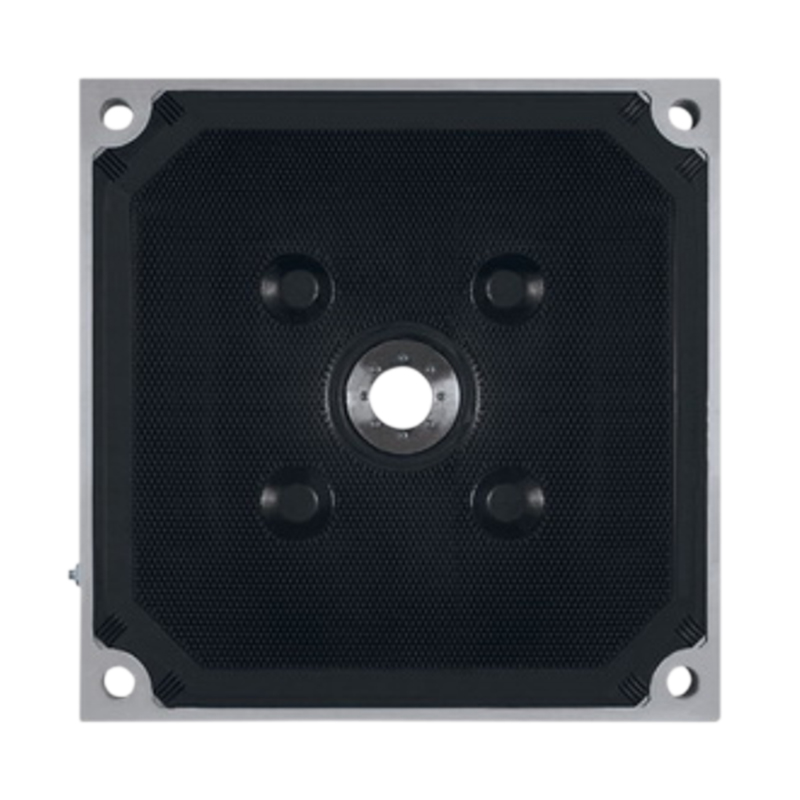

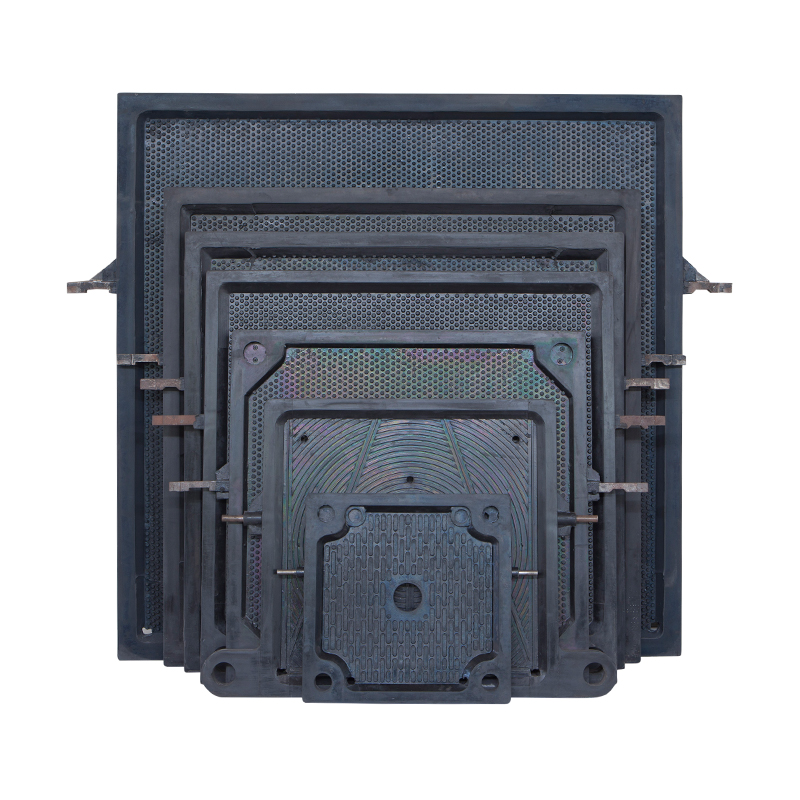

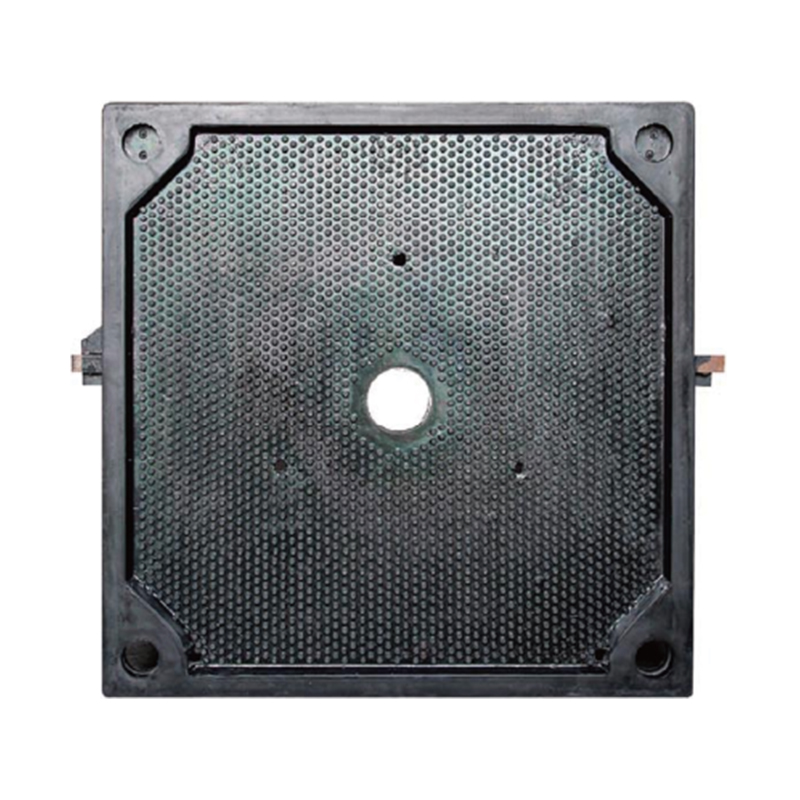

Composite rubber filter plate

Product features: Our rubber sheet series products have independent intellectual property rights and have obtained national patents.

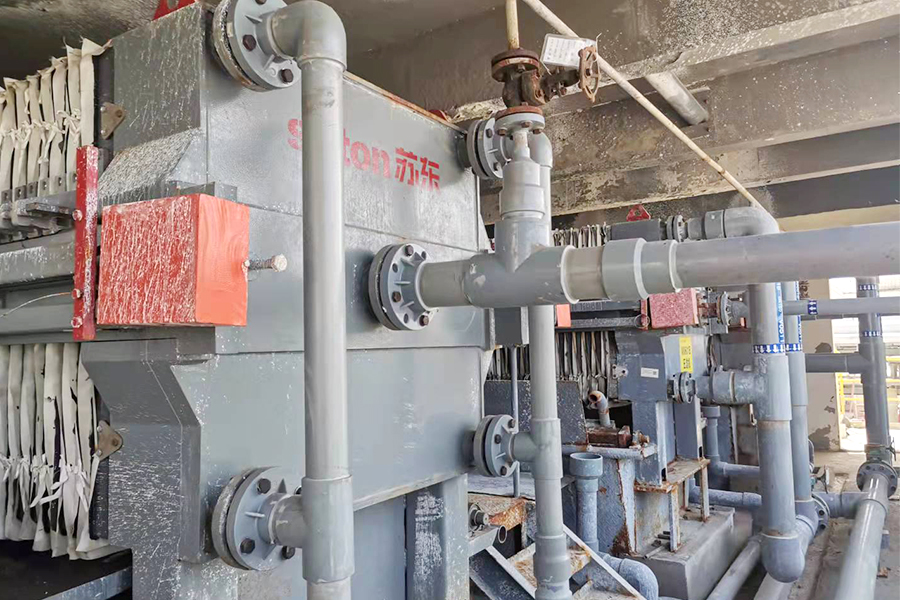

Product advantages: This filter plate is made of high-quality chloroprene rubber raw material, which is mixed and modified and then high-pressure composite vulcanized with a steel frame to ensure the rigidity of the filter plate while ensuring the elasticity of the rubber. The sealing surface is elastic contact, has good sealing performance, high strength, and a single-sided pressure of 0.6-1.2MPa. It has good corrosion resistance and anti-aging performance. The filter plate can withstand temperatures of up to 120°C. The filter plate is designed to have a service life of more than 8 years. The steel frame can be recycled and re-rubbed many times, and the comprehensive maintenance cost is low.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

A Diaphragm Filter Press is an advanced type of filtration equipment designed to separate solid part...

READ MORE -

The Chamber Filter Press is a vital piece of equipment in wastewater treatment because of its effici...

READ MORE -

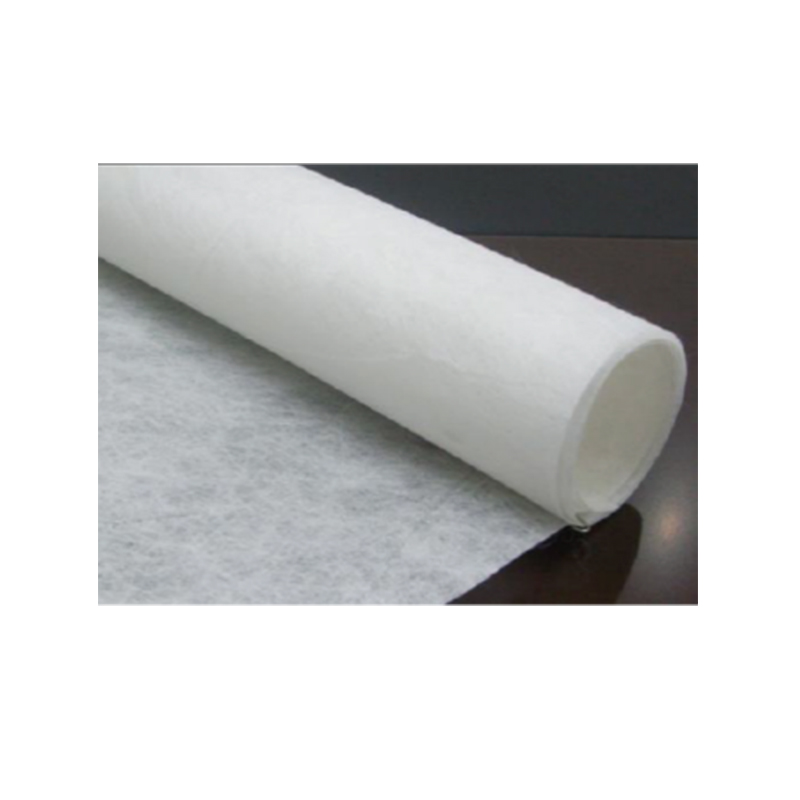

1. Separation of Solids and Liquids Filter press cloths play a crucial role in the filtration proces...

READ MORE -

1. Choose the Right Material for Filter Press Plates The material of filter press plates is crucial ...

READ MORE -

Frame filter presses are widely used in various industrial and environmental treatment fields, espec...

READ MORE

What is the principle of activated carbon adsorption in Composite Rubber Filter Plated?

Jiangsu Sudong Chemical Machinery Co., Ltd. was established in 1956. We have been deeply engaged in the field of filter press technology and have 30 years of professional experience. We have won wide recognition in the domestic market and demonstrated the charm of "Made in China" on the international stage. The following will focus on one of our products, Composite Rubber Filter Plated, and will reveal the principle and application of activated carbon adsorption technology in Composite Rubber Filter Plated.

Activated carbon is a porous carbon-containing substance with strong adsorption capacity and is widely used in many fields such as air purification, water treatment, and food decolorization. It has countless tiny pores and surface functional groups, which can absorb and fix various gas molecules, impurities in liquids and even some dissolved solid substances like a sponge. This adsorption is efficient and extensive, and is an indispensable key element in Composite Rubber Filter Plated. In the Composite Rubber Filter Plated carefully built by Jiangsu Sudong Chemical Machinery Co., Ltd., activated carbon adsorption technology is cleverly integrated into the design of the rubber filter plate. This product inherits the excellent elasticity and sealing performance of traditional rubber filter plates, and also maximizes the adsorption advantages of activated carbon through innovative material combinations and process designs.

1. Material selection and processing

Jiangsu Sudong Chemical Machinery Co., Ltd. uses high-quality chloroprene rubber as the base material. Chloroprene rubber is known for its excellent oil resistance, solvent resistance, weather resistance and anti-aging properties, and is an ideal material for manufacturing high-performance filter elements. In the raw material preparation stage, we further improve its physical properties and chemical stability by precisely mixing and modifying chloroprene rubber.

2. Integration of activated carbon layer

During the manufacturing process of the rubber filter plate, Jiangsu Sudong Chemical Machinery Co., Ltd. added a layer of activated carbon layer. This layer of activated carbon is evenly distributed in the rubber matrix to form an adsorption structure. Through the high-pressure vulcanization process, the activated carbon layer is closely combined with the rubber matrix, which ensures the overall strength of the filter plate and ensures that the activated carbon can fully exert its adsorption efficiency.

3. Efficient adsorption mechanism

When the fluid to be treated passes through the Composite Rubber Filter Plated, the activated carbon layer begins its purification journey. When the organic matter, odor molecules, pigments and other impurities in the fluid flow through the activated carbon layer, they will be attracted and firmly adsorbed by the rich pores and functional groups on its surface. This process is fast and effective, which can reduce the content of pollutants in the fluid and improve the filtering effect.

4 The adsorption of activated carbon is mainly based on two principles: physical adsorption and chemical adsorption.

Physical adsorption: This is the most common form of activated carbon adsorption. Because there are a large number of micropores and mesopores on the surface of activated carbon, the diameter of these pores is much smaller than the molecular diameter of the adsorbed substance, so it can produce a strong capillary attraction. When the molecules or atoms in the fluid approach the surface of activated carbon, they will be attracted by this attraction and stay in the pores, thereby achieving physical adsorption.

Chemical adsorption: In addition to physical adsorption, a certain number of functional groups (such as hydroxyl, carboxyl, etc.) are distributed on the surface of activated carbon. These functional groups have certain chemical activity and can react chemically with certain substances in the fluid to form chemical bonds. This adsorption process based on chemical reaction is called chemical adsorption. Chemical adsorption is usually stronger than physical adsorption, but also relatively slow.

In Composite Rubber Filter Plated, the adsorption of activated carbon is often the result of the combined action of physical adsorption and chemical adsorption. The two complement each other and jointly improve the filtration efficiency and purification capacity of the filter plate.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt