As China Fully automatic vibration filter press Manufacturers and Fully automatic vibration filter press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

Fully automatic vibration filter press

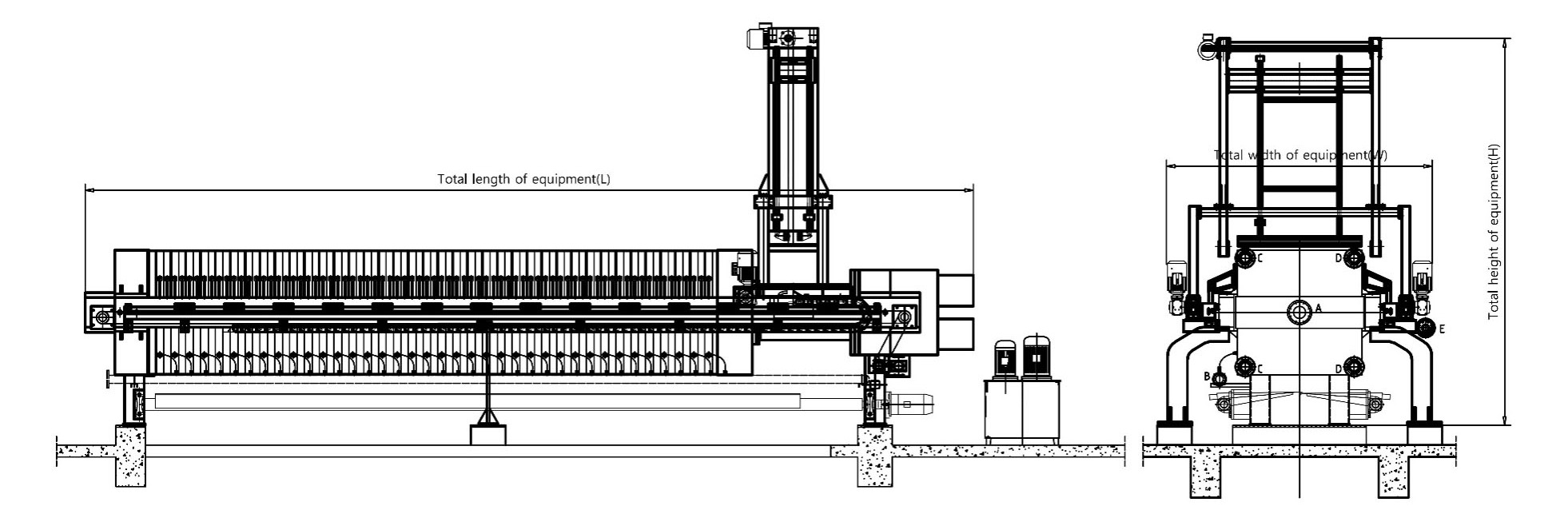

Product features: The fully automated control system of the equipment covers multiple links such as feeding, filtration, pressing, vibrating, unloading, and cleaning, ensuring that the entire operation process is smooth, efficient, and safe.

Product advantages: The fully automatic vibrating filter press vibrates the filter plate through a high-frequency vibration device, which can effectively reduce the adhesion of the filter cake, improve the automatic unloading efficiency of the filter cake, ensure the cleanliness of the filter cloth, and thus extend the service life of the filter cloth. The vibration system starts automatically after the filtration cycle ends, and quickly shakes off the filter cake through vibration, making the filter cake unloading more thorough, avoiding manual intervention, and improving overall production efficiency. The vibration device of the fully automatic vibration filter press can not only optimize the unloading process, but also keep the filter plates unobstructed, prevent blockage, and improve the filtration quality.

Product details

| Specification | Number Of Filter Plates | Filter Chamber Volume(m3) | Overall Dimensions(mm) | Filtration Pressure | Pressing Pressure | Matching Power (KW) | Weight Of Single Machine(Kg) |

| XAMYZG20/800-U | 9 | 0.3 | 3755×1900×3300 | ≤0.8 | ≤1.2 | 5.65 | 3100 |

| XAMYZG30/800-U | 14 | 0.45 | 5385×1900×3300 | 3400 | |||

| XAMYZG40/800-U | 19 | 0.6 | 5005×1900×3300 | 3800 | |||

| XAMYZG45/800-U | 21 | 0.675 | 5285×1900×3300 | 4000 | |||

| XAMYZG50/800-U | 24 | 0.75 | 5635×1900×3300 | 4200 | |||

| XAMYZG60/800-U | 29 | 0.9 | 6265×1900×3300 | 4600 | |||

| XAMYZG80/800-U | 39 | 1.2 | 7745×1900×3300 | 5450 | |||

| XAMYZG40/1000-U | 24 | 0.6 | 3885×2200×3600 | 4600 | |||

| XAMYZG50/1000-U | 30 | 0.75 | 5235×2200×3600 | 4900 | |||

| XAMYZG60/1000-U | 36 | 0.9 | 5665×2200×3600 | 5250 | |||

| XAMYZG70/1000-U | 42 | 1.05 | 6065×2200×3600 | 5550 | |||

| XAMYZG80/1000-U | 48 | 1.2 | 6530×2200×3600 | 5900 | |||

| XAMYZG90/1000-U | 54 | 1.35 | 6945×2200×3600 | 6300 | |||

| XAMYZG100/1000-U | 60 | 1.5 | 7365×2200×3600 | 6700 | |||

| XAMYZG110/1000-U | 66 | 1.65 | 7795×2200×3600 | 7050 | |||

| XAMYZG120/1000-U | 72 | 1.8 | 8065×2200×3600 | 7250 | |||

| XAMYZG100/1250-U | 38 | 1.5 | 6200×2600×4100 | ≤0.8 | ≤1.2 | 10.25 | 8200 |

| XAMYZG120/1250-U | 46 | 1.8 | 6800×2600×4100 | 8700 | |||

| XAMYZG140/1250-U | 52 | 2.1 | 7250×2600×4100 | 9100 | |||

| XAMYZG150/1250-U | 56 | 2.25 | 7550×2600×4100 | 9500 | |||

| XAMYZG160/1250-U | 60 | 2.4 | 7850×2600×4100 | 10000 | |||

| XAMYZG180/1250-U | 68 | 2.7 | 8450×2600×4100 | 10700 | |||

| XAMYZG200/1250-U | 76 | 3 | 9050×2600×4100 | 11600 | |||

| XAMYZG220/1250-U | 82 | 3.3 | 9500×2600×4100 | 12000 | |||

| XAMYZG250/1250-U | 94 | 3.75 | 10400×2600×4100 | 13500 | |||

| XAMYZG200/1500-U | 52 | 3 | 8165×3100×5100 | ≤0.8 | ≤1.2 | 10.75 | 21100 |

| XAMYZG250/1500-U | 64 | 3.75 | 9155×3100×5100 | 23200 | |||

| XAMYZG300/1500-U | 76 | 4.5 | 10145×3100×5100 | 25300 | |||

| XAMYZG350/1500-U | 90 | 5.3 | 11805×3100×5100 | 27800 | |||

| XAMYZG400/1500-U | 102 | 6 | 12795×3100×5100 | 29500 | |||

| XAMYZG450/1500-U | 116 | 6.75 | 13955×3100×5100 | 31200 | |||

| XAMYZG500/1500-U | 128 | 7.5 | 14945×3100×5100 | 33200 | |||

| XAMYZG 600/2000-U | 84 | 10.5 | 11980×3600×6200 | ≤0.8 | ≤1.2 | 17.15 | 48000 |

| XAMYZG 700/2000-U | 100 | 12.25 | 13360×3600×6200 | 52000 | |||

| XAMYZG800/2000-U | 116 | 14 | 14660×3600×6200 | 56000 | |||

| XAMYZG900/2000-U | 132 | 15.75 | 16045×3600×6200 | 60000 | |||

| XAMYZG1000/2000-U | 144 | 17.5 | 17085×3600×6200 | 63000 |

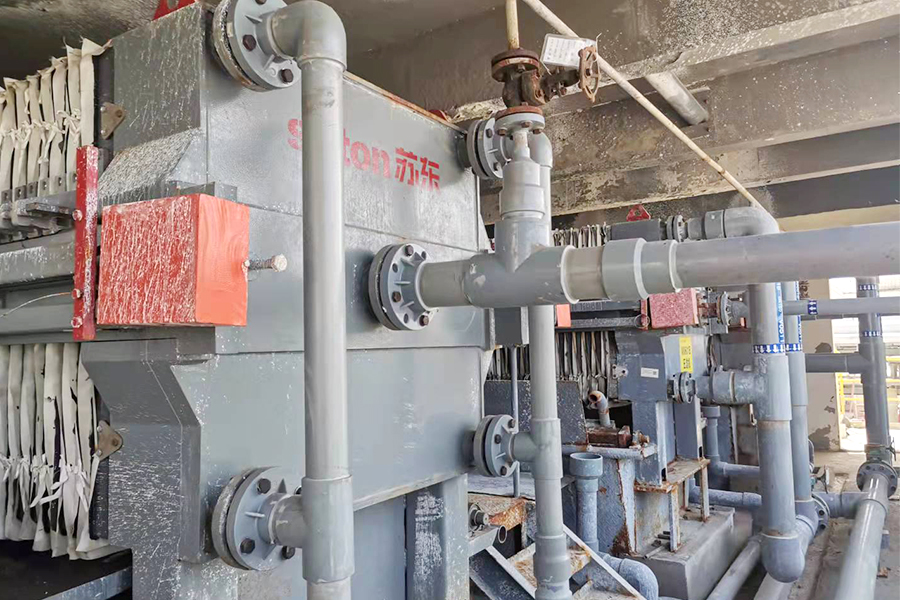

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

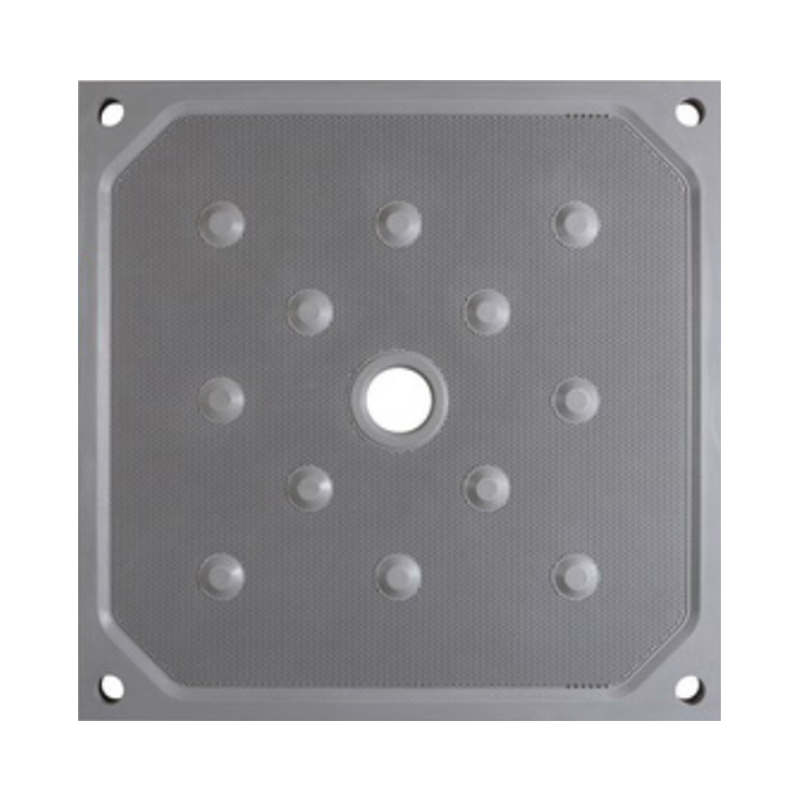

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

1.How Does the Vibration Device Enhance the Unloading Process and Filtration Quality?

The vibration device integrated into a fully automatic vibration filter press plays a crucial role in optimizing both the unloading process and the overall filtration quality. In traditional filter presses, one of the common challenges is the accumulation of filtered solids, or "cake," on the filter plates, which can lead to blockages and inconsistent filtration results. The vibration device addresses this issue by gently shaking the filter plates at the end of the filtration cycle, facilitating the easy and complete removal of the filter cake.

This vibration mechanism is meticulously engineered to deliver just the right amount of force to dislodge the cake without damaging the filter plates or the cloths. By ensuring that the filter cake is efficiently removed, the vibration device not only speeds up the unloading process but also prepares the filter press for the next cycle more quickly, thereby improving the overall operational efficiency. This is particularly beneficial in industries where the filtration process must be repeated continuously, such as in chemical processing, wastewater treatment, and mining operations.

The vibration device contributes to maintaining the cleanliness of the filter plates. Over time, residual materials can build up on the plates, leading to blockages that can compromise the filtration quality. By keeping the plates unobstructed, the vibration device helps ensure that the flow of liquid through the press remains consistent, which is critical for achieving high-quality filtration results. This feature is especially important when dealing with fine particles or sticky substances that are prone to clogging.

The impact of the vibration device on filtration quality cannot be overstated. By preventing blockages and ensuring that the filter plates are always in optimal condition, the device helps to produce a filtrate that is free of impurities and a filter cake that is consistent in texture and dryness. This level of precision is essential for industries that require high-purity outputs, such as pharmaceuticals, food processing, and fine chemicals.

2.What Are the Advantages of a Fully Automated Control System in Vibration Filter Presses?

The Fully Automatic Vibration Filter Press is a sophisticated technology designed to manage every aspect of the filtration process, from feeding to unloading. This system is the backbone of the filter press, ensuring that each phase of the operation is executed with precision and efficiency. The automation covers multiple critical stages, including feeding, filtration, pressing, vibration, unloading, and cleaning, which collectively contribute to a seamless and efficient filtration process.

One of the primary advantages of a fully automated control system is its ability to optimize the feeding process. The system precisely controls the amount and rate of slurry fed into the filter press, ensuring that the filter plates are evenly loaded. This even distribution is crucial for achieving consistent filtration results, as it prevents the formation of uneven filter cakes, which can lead to inefficiencies and reduced filtration quality. Moreover, the automated system adjusts feeding parameters in real-time based on the characteristics of the slurry, ensuring that the filtration process is always optimized.

During the filtration and pressing stages, the automation system monitors and adjusts the pressure applied to the filter plates, ensuring that the filtration is thorough and that the maximum amount of liquid is extracted from the slurry. This level of control not only improves the efficiency of the filtration process but also helps to produce a drier filter cake, which is easier to handle and dispose of. The system’s ability to maintain consistent pressure throughout the cycle is especially important in applications where the filtration needs to meet stringent quality standards.

The automation also extends to the vibration and unloading processes, where the system ensures that the filter plates are vibrated at the right moment and with the right intensity to facilitate the smooth removal of the filter cake. This reduces the need for manual intervention, minimizes downtime, and increases the overall productivity of the filter press. Additionally, the automated control system manages the cleaning of the filter plates, ensuring that they are free of residues before the next cycle begins. This not only improves the longevity of the filter plates but also ensures that the filtration quality remains high over time.

3.Why Is the Fully Automatic Vibration Filter Press the Future of Industrial Filtration?

The fully automatic vibration filter press represents a significant advancement in industrial filtration technology, offering numerous benefits that make it the future of filtration in various industries. As industries continue to seek ways to improve efficiency, reduce costs, and enhance the quality of their products, the demand for more advanced filtration solutions is growing. The fully automatic vibration filter press meets this demand by combining cutting-edge technology with robust engineering, delivering a solution that is both highly efficient and reliable.

One of the key reasons why the fully automatic vibration filter press is considered the future of industrial filtration is its ability to significantly reduce labor costs. Traditional filter presses often require a high level of manual intervention, which can be both time-consuming and costly. With a fully automatic system, the need for manual labor is greatly reduced, as the press can operate independently, from feeding to unloading. This not only lowers operational costs but also frees up workers to focus on other critical tasks, thereby improving overall productivity.

In addition to cost savings, the fully automatic vibration filter press offers superior consistency and quality in filtration. The automation ensures that each cycle is carried out with precision, producing consistent results that are difficult to achieve with manual operation. This level of consistency is crucial in industries where the quality of the filtrate and filter cake must meet strict standards. Whether in pharmaceuticals, food processing, or chemical manufacturing, the ability to consistently produce high-quality outputs gives companies a competitive edge in their respective markets.

Another factor driving the adoption of fully automatic vibration filter presses is the increasing focus on environmental sustainability. These presses are designed to maximize resource efficiency, reducing waste and energy consumption. The precise control over the filtration process allows for the optimal use of materials, minimizing waste and ensuring that the maximum amount of product is recovered from each batch of slurry. Furthermore, the automation system can be programmed to use only the necessary amount of water and energy, further reducing the environmental footprint of the filtration process.

The fully automatic vibration filter press is also designed with scalability in mind. As industries grow and their filtration needs increase, the modular design of these presses allows for easy expansion and adaptation. This flexibility ensures that companies can scale their operations without the need for significant investment in new equipment. The ability to adapt to changing production demands makes the fully automatic vibration filter press a future-proof solution for industries looking to stay ahead of the curve.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt