As China Quick Opening Filter Press Manufacturers and Quick Opening Filter Press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

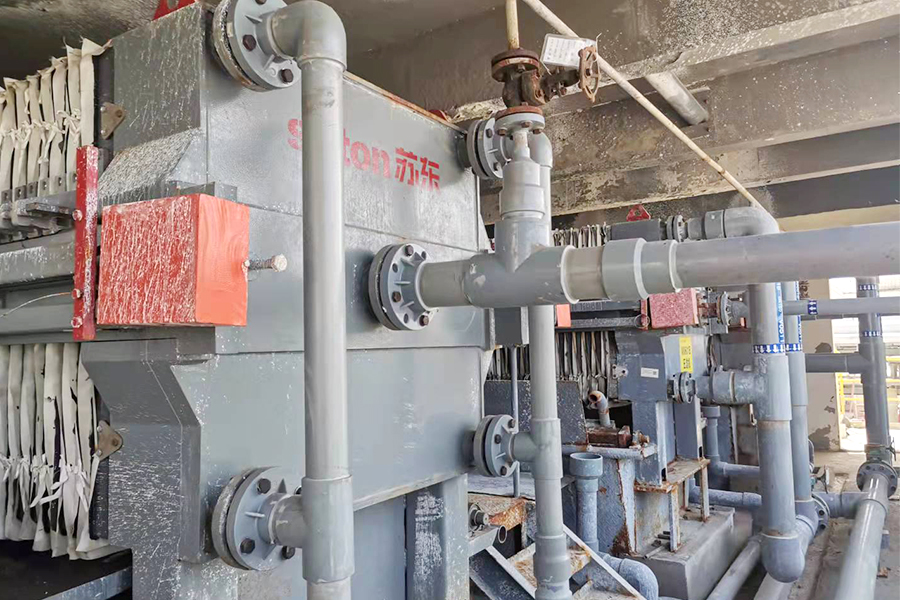

Quick Opening Filter Press

Application range: The product is widely used in solid-liquid separation in petrochemical, nonferrous metallurgy, fine chemical, and other industries.

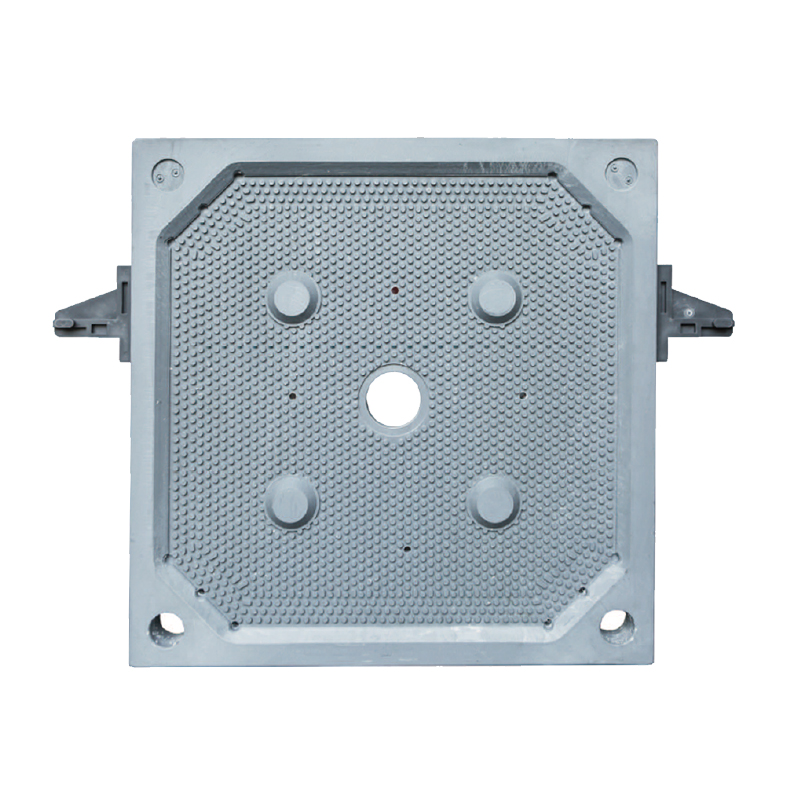

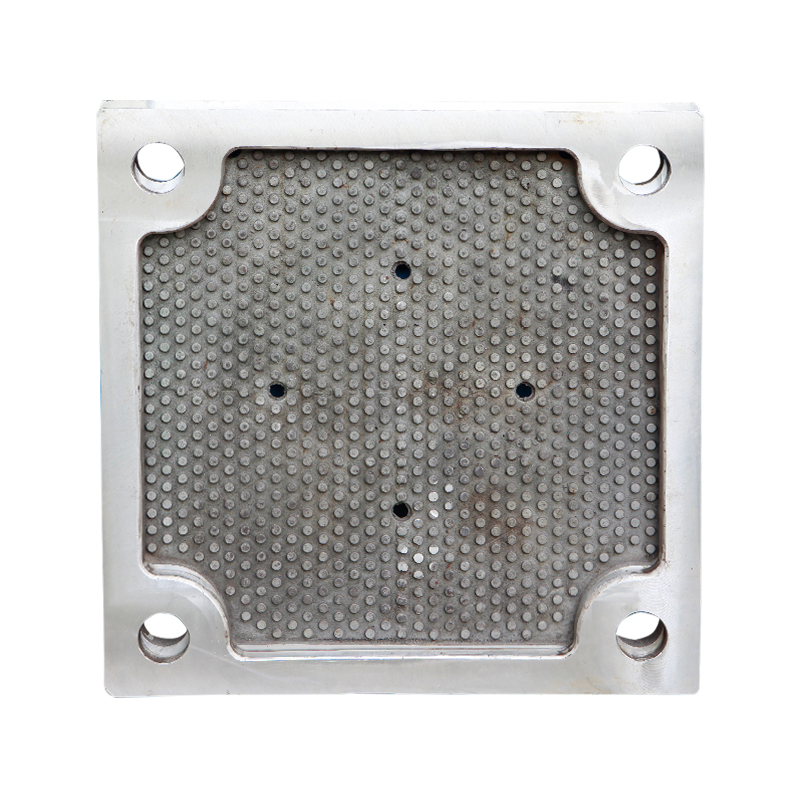

Product features: It can be used with an automatic vibration device to realize vibration-assisted unloading of filter plates pulled apart at equal distances and can realize fully automatic unloading.

Product advantages: The filter press can be quickly opened at one time, driven by an extended oil cylinder, and with an extended frame, each filter plate is connected through a stainless steel chain (or slide), and the filter plates are fully opened at one time under the drive of the clamping plate. The plate pulling speed is fast, the unloading is automatically assisted, the structure is compact, and labor-saving, and the degree of automation is high.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

1. What is a quick-opening filter plate filter press?

Quick Opening Filter Press is an advanced filtration equipment designed to speed up the filtration process and is widely used in chemical, pharmaceutical and sewage treatment industries. Compared with traditional filter presses, quick-opening filter plate filter presses have significant advantages, especially in improving work efficiency and shortening production cycles. This equipment greatly reduces the time required for each filtration cycle by opening all filter plates at once, thereby improving overall production efficiency.

The core feature of this equipment is its ability to quickly open all filter plates, thanks to the use of an extended cylinder drive system. This system not only ensures that the filter plates can move synchronously at a high speed, but also operates stably under high load conditions. To support this quick-opening process, the frame of the plate filter press has also been extended and reinforced to ensure structural stability and durability during high-speed operation.

Quick-opening plate filter presses are designed with the challenges that may be encountered in a variety of industrial applications. Its overall design enables it to handle various types of filter residue, whether it is granular, muddy or fibrous filter residue, it can be efficiently filtered and unloaded by this equipment. For factories that need to frequently replace filter plates or process large quantities of materials, the quick-opening filter plate filter press is undoubtedly an ideal choice.

The design of the quick-opening filter plate filter press also focuses on ease of operation and maintenance. Since all filter plates can be opened at the same time, the number of manual operations can be significantly reduced and the labor intensity of the operator is reduced. This design also reduces equipment downtime during the filtration process, thereby improving the overall operating efficiency of the production line. In summary, the quick-opening plate filter press not only provides higher production efficiency, but also provides great flexibility and adaptability for various industrial applications through its design features.

2. How does the quick opening mechanism work?

The core function of the Quick Opening Filter Press is its ability to quickly open all filter plates in one operation, which is often a time-consuming process in traditional filter presses. The working principle of this mechanism is based on an extended cylinder drive system and a stainless steel chain or slide mechanism. This design ensures that each filter plate is driven in a precise manner, allowing for synchronized movement and efficient operation.

During operation, the extended cylinder system plays a vital role. It ensures consistent speed and force throughout the opening process by applying uniform pressure to all filter plates. This not only speeds up the entire filtration process, but also ensures that the filter plate will not be damaged by uneven pressure during the opening and closing process. The extended cylinder also provides enough power to drive large and multiple filter plates, allowing the quick-opening filter plate filter press to handle large-scale filtration tasks.

A stainless steel chain or slide mechanism is responsible for driving the movement of the filter plate. This mechanism is designed with high-frequency operation in mind and is therefore extremely durable and stable. The choice of stainless steel material allows these chains or slides to maintain good performance in harsh industrial environments and are less susceptible to corrosion or wear. Through this sophisticated drive mechanism, the filter plates can move simultaneously in one operation, greatly shortening the filtration cycle.

The design of the quick-opening filter plate filter press also takes into account the ease of maintenance of the equipment. Because the filter plates can be moved and opened simultaneously, mechanical component complexity and failure points are reduced. Maintenance personnel can more easily inspect and maintain equipment, reducing equipment downtime. This efficient design makes the quick-opening filter plate filter press extremely reliable and productive in a variety of industrial applications.

3. What are the advantages of automatic vibration and unloading?

To further improve the efficiency of the Quick Opening Filter Press, the equipment can be equipped with an automatic vibration device. This device provides vibration assistance after the filter plate is opened, and is especially suitable for handling filter residues that are sticky or difficult to unload. This design not only enhances the unloading efficiency of the filter residue, but also makes the entire filtration process more automated, reducing the need for manual intervention.

The working principle of the automatic vibration device is to apply uniform vibration during the separation process of the filter plate. This vibration helps loosen and separate the filter residue attached to the filter plate, making it easier to fall off the filter plate surface. This is especially useful when dealing with filter residues such as sludge, fibrous or other easily adhered materials. This design not only improves filtration efficiency, but also ensures that the filter plates are thoroughly cleaned during each filtration cycle, thereby extending the life of the equipment.

In addition to vibration assistance, the quick-opening filter plate filter press also has a fully automatic discharge function. When the filter plate is pulled to a predetermined equidistant position, the equipment will automatically perform the unloading operation without manual intervention by the operator. This automated design greatly reduces labor costs while improving production safety. Because there is no need to manually handle heavy filter residue or enter the equipment for cleaning, the operator's working environment becomes safer and the risks of equipment operation are reduced.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt