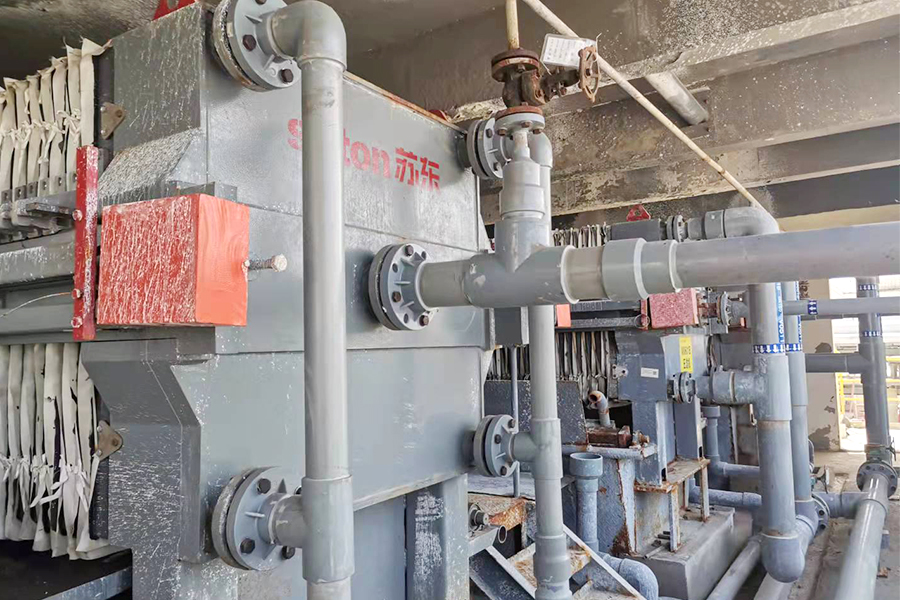

As China Polypropylene plate diaphragm filter press Manufacturers and Polypropylene plate diaphragm filter press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

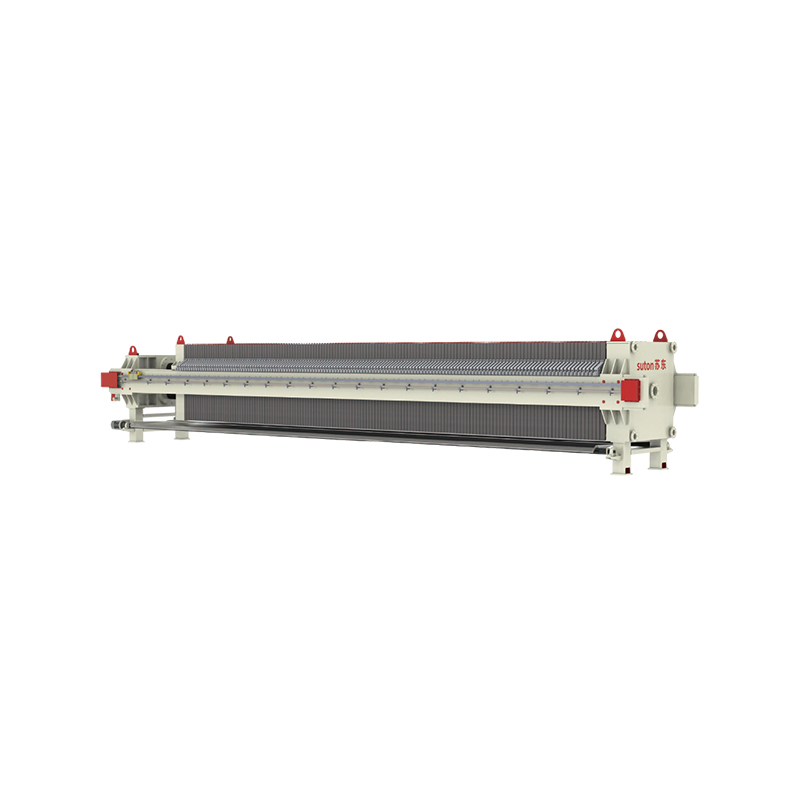

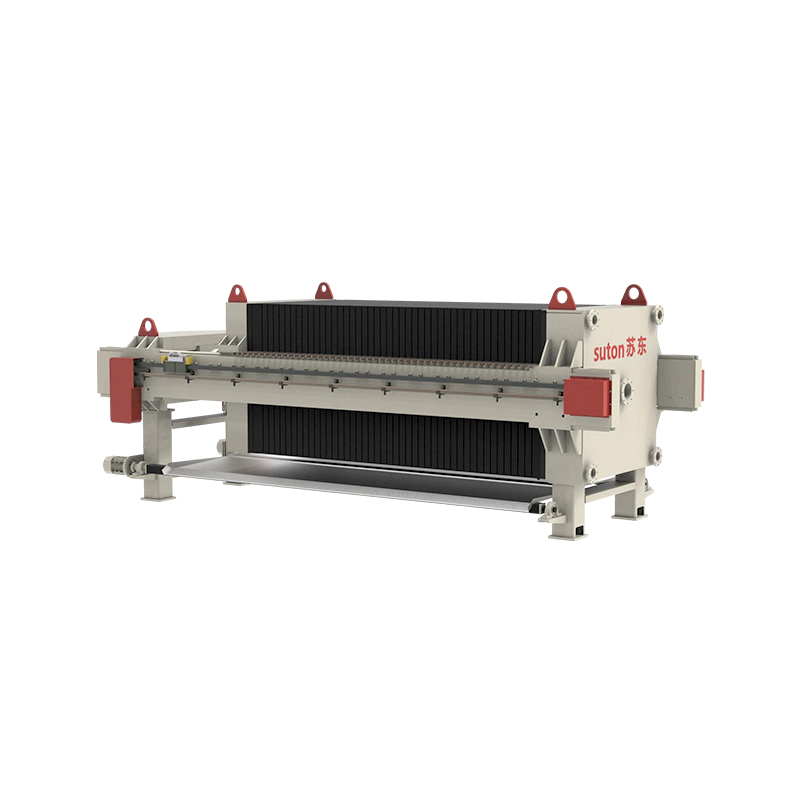

Polypropylene plate diaphragm filter press

Application range: The products are widely used in industries with high requirements for solid-liquid separation, such as municipal sludge, industrial sludge, fine chemicals, food, and medicine.

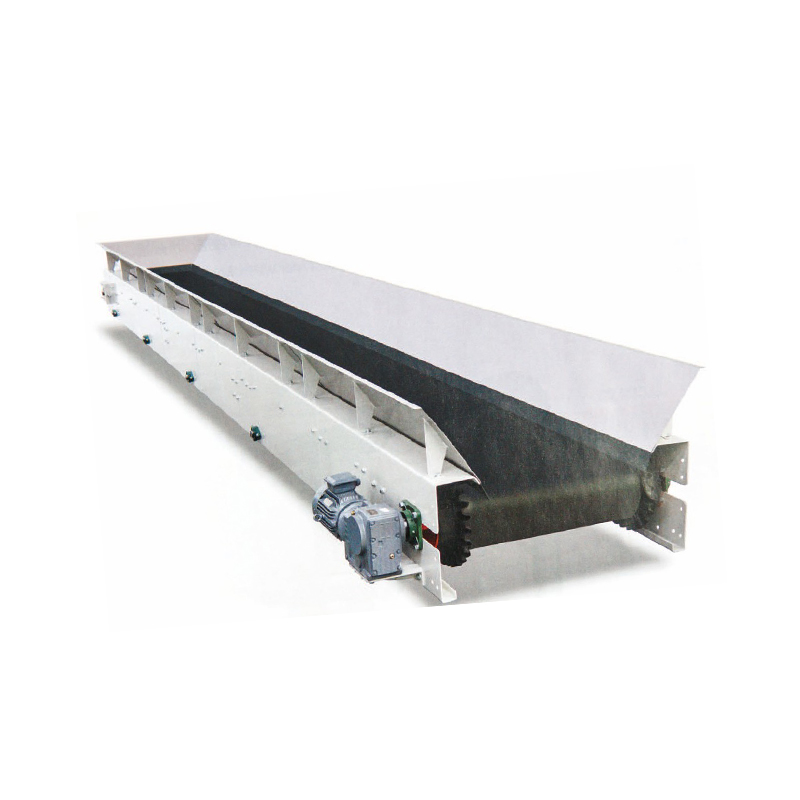

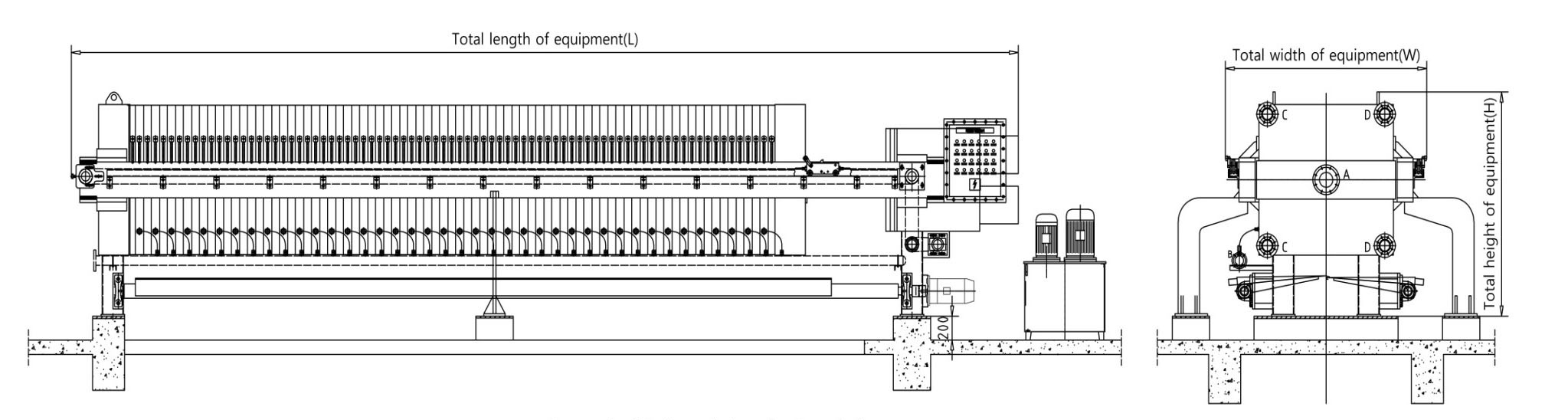

Product features: The machine can be equipped with various configurations such as automatic plate pulling, automatic liquid connection, automatic mud unloading, automatic filter cloth washing, PLC automatic control, etc. The operation panel is simple and safe, and the degree of automation is high.

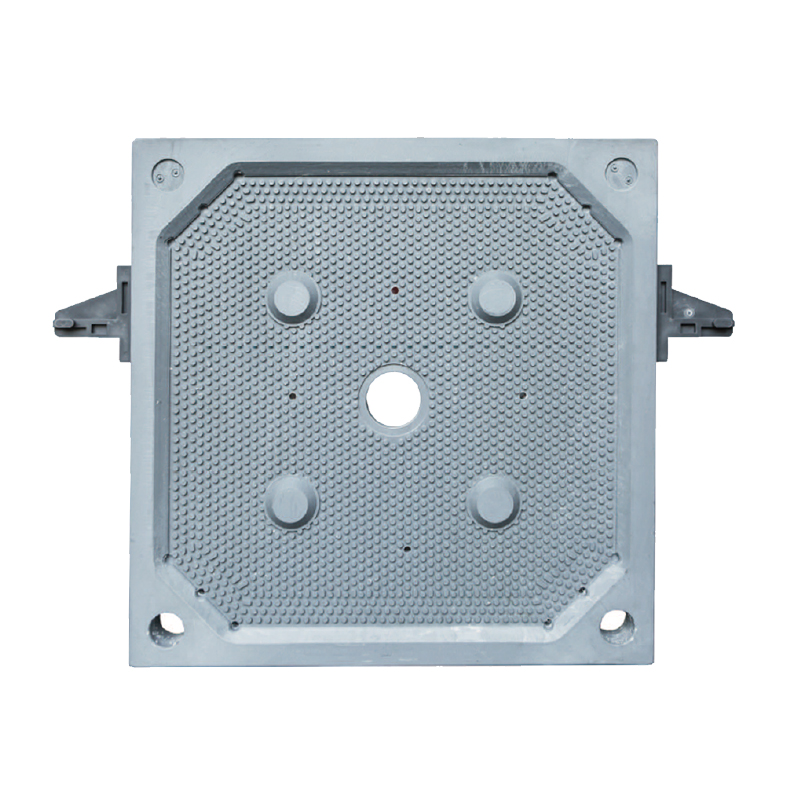

Product advantages: The polypropylene diaphragm filter plate is made of high-quality TPE elastomer + alkali-free glass fiber polypropylene material. The diaphragm pressing pressure can reach 1.6MPa (the pressing pressure can be designed according to customer requirements, up to 4.0MPa); the overall special flow channel design is adopted, and the filtration speed is increased by about 20%; compared with the chamber filter press, the moisture content of the mud cake is reduced by 20%-40%. The frame is made of high-strength steel welded parts, with high frame strength, stable structure, and long service life.

Product details

| Specification | Number of Filter Plates | Chamber Volume(m3) | Overall Dimensions(mm) | Filter Plate Size | Filtration Pressure | Pressing Pressure | Matching Power (KW) | Weight Of Single Machine(Kg) |

| XAMYZG5/630-U | 8 | 0.075 | 2600×1050×1140 | 630×630×60/65 | ≤0.8 | ≤1.2 | 1.5+0.3 | 1200 |

| XAMYZG8/630-U | 12 | 0.12 | 2850×1050×1140 | 630×630×60/65 | 1400 | |||

| XAMYZG10/630-U | 16 | 0.15 | 3100×1050×1140 | 630×630×60/65 | 1500 | |||

| XAMYZG15/630-U | 24 | 0.225 | 3600×1050×1140 | 630×630×60/65 | 1700 | |||

| XAMYZG20/630-U | 36 | 0.3 | 4100×1050×1140 | 630×630×60/65 | 1900 | |||

| XAMYZG20/800-U | 9 | 0.3 | 3270×1200×1500 | 800×800×60/65 | ≤0.8 | ≤1.2 | 4 | 3100 |

| XAMYZG30/800-U | 14 | 0.45 | 3900×1200×1500 | 800×800×60/65 | 3400 | |||

| XAMYZG40/800-U | 19 | 0.6 | 4520×1200×1500 | 800×800×60/65 | 3800 | |||

| XAMYZG45/800-U | 21 | 0.675 | 4800×1200×1500 | 800×800×60/65 | 4000 | |||

| XAMYZG50/800-U | 24 | 0.75 | 5150×1200×1500 | 800×800×60/65 | 4200 | |||

| XAMYZG60/800-U | 29 | 0.9 | 5780×1200×1500 | 800×800×60/65 | 4600 | |||

| XAMYZG80/800-U | 39 | 1.2 | 7260×1200×1500 | 800×800×60/65 | 5450 | |||

| XAMYZG40/1000-U | 24 | 0.6 | 4350×1500×1600 | 1000×1000×70/72 | 4600 | |||

| XAMYZG50/1000-U | 30 | 0.75 | 4770×1500×1600 | 1000×1000×70/72 | 4900 | |||

| XAMYZG60/1000-U | 36 | 0.9 | 5200×1500×1600 | 1000×1000×70/72 | 5250 | |||

| XAMYZG70/1000-U | 42 | 1.05 | 5600×1500×1600 | 1000×1000×70/72 | 5550 | |||

| XAMYZG80/1000-U | 48 | 1.2 | 6050×1500×1600 | 1000×1000×70/72 | 5900 | |||

| XAMYZG90/1000-U | 54 | 1.35 | 6480×1500×1600 | 1000×1000×70/72 | 6300 | |||

| XAMYZG100/1000-U | 60 | 1.5 | 6900×1500×1600 | 1000×1000×70/72 | 6700 | |||

| XAMYZG110/1000-U | 66 | 1.65 | 7330×1500×1600 | 1000×1000×70/72 | 7050 | |||

| XAMYZG120/1000-U | 72 | 1.8 | 7600×1500×1600 | 1000×1000×70/72 | 7250 | |||

| XAMYZG100/1250-U | 38 | 1.5 | 5770×1700×1900 | 1250×1250×72/78 | ≤0.8 | ≤1.2 | 7.5+1.1 | 8200 |

| XAMYZG120/1250-U | 46 | 1.8 | 6370×1700×1900 | 1250×1250×72/78 | 8700 | |||

| XAMYZG140/1250-U | 52 | 2.1 | 6820×1700×1900 | 1250×1250×72/78 | 9100 | |||

| XAMYZG150/1250-U | 56 | 2.25 | 7120×1700×1900 | 1250×1250×72/78 | 9500 | |||

| XAMYZG160/1250-U | 60 | 2.4 | 7420×1700×1900 | 1250×1250×72/78 | 10000 | |||

| XAMYZG180/1250-U | 68 | 2.7 | 8020×1700×1900 | 1250×1250×72/78 | 10700 | |||

| XAMYZG200/1250-U | 76 | 3 | 8620×1700×1900 | 1250×1250×72/78 | 11600 | |||

| XAMYZG220/1250-U | 82 | 3.3 | 9070×1700×1900 | 1250×1250×72/78 | 12000 | |||

| XAMYZG250/1250-U | 94 | 3.75 | 10120×1700×1900 | 1250×1250×72/78 | 13500 | |||

| XAMYZG200/1500-U | 52 | 3 | 7660×2400×2020 | 1500×1500×80/85 | ≤0.8 | ≤1.2 | 8+1.1 | 21100 |

| XAMYZG250/1500-U | 64 | 3.75 | 8650×2400×2020 | 1500×1500×80/85 | 23200 | |||

| XAMYZG300/1500-U | 76 | 4.5 | 9640×2400×2020 | 1500×1500×80/85 | 25300 | |||

| XAMYZG350/1500-U | 90 | 5.3 | 11300×2400×2020 | 1500×1500×80/85 | 27800 | |||

| XAMYZG400/1500-U | 102 | 6 | 12290×2400×2020 | 1500×1500×80/85 | 29500 | |||

| XAMYZG450/1500-U | 116 | 6.75 | 13450×2400×2020 | 1500×1500×80/85 | 31200 | |||

| XAMYZG500/1500-U | 128 | 7.5 | 14440×2400×2020 | 1500×1500×80/85 | 33200 | |||

| XAMYZG 600/2000-U | 84 | 10.5 | 11920×2900×2600 | 2000×2000×83/90 | ≤0.8 | ≤1.2 | 11.5+4 | 48000 |

| XAMYZG 700/2000-U | 100 | 12.25 | 13300×2900×2600 | 2000×2000×83/90 | 52000 | |||

| XAMYZG800/2000-U | 116 | 14 | 14600×2900×2600 | 2000×2000×83/90 | 56000 | |||

| XAMYZG900/2000-U | 132 | 15.75 | 15985×2900×2600 | 2000×2000×83/90 | 60000 | |||

| XAMYZG1000/2000-U | 144 | 17.5 | 17025×2900×2600 | 2000×2000×83/90 | 63000 |

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

Compared with traditional chamber filter presses, how does the Polypropylene Plate Diaphragm Filter Press reduce the moisture content of the mud cake by 20%-40%?

In modern solid-liquid separation technology, the emergence of Polypropylene Plate Diaphragm Filter Press marks a significant technological progress. Compared with traditional chamber filter presses, it shows significant advantages in reducing the moisture content of mud cakes. . As a professional manufacturer, we deeply understand the unique mechanism and advantages of this equipment in this regard, and are committed to providing efficient and reliable solutions.

The key to increasing the moisture content of the mud cake lies in the design and material of the filter plate. Our polypropylene membrane filter plate uses high-quality TPE elastomer and alkali-free glass fiber reinforced polypropylene material. This high-performance material combination not only provides excellent mechanical strength, but also has excellent elasticity and corrosion resistance. The filter plate design includes unique membrane technology that allows the filter plate to be pressurized multiple times during the pressing phase, effectively squeezing out remaining liquid from the filter cake. Different from the single pressurization method of traditional chamber filter press, our membrane filter plate adopts higher pressure and finer flow channel design during the pressurization process, so that the liquid can be more completely squeezed out of the filter cake. , thereby achieving a significant reduction in the moisture content of the mud cake.

The innovation in flow channel design is also an important factor in reducing the moisture content of the mud cake. Our filter plate design adopts a special flow channel configuration, which can greatly increase the filtration speed and effectively reduce the retention time of the filtrate. This flow channel design optimizes the hydrodynamic performance of the filter plate, allowing liquid to be evenly distributed and quickly discharged inside the filter plate, further reducing the liquid content in the filter cake. In addition, the optimization of the flow channel also reduces the probability of blockage of the filter cloth, thereby reducing the cleaning frequency and maintenance cost of the filter cloth.

Polypropylene Plate Diaphragm Filter Press can operate at a standard pressure of 1.6 MPa, while the design pressure can be increased to a maximum of 4.0 MPa according to different process requirements. This high-pressure design allows the filter plate to exert greater pressure during the pressing process, thereby squeezing out the liquid in the filter cake more effectively. In comparison, the pressing pressure of traditional chamber filter presses is usually lower and cannot achieve the same effect. Through this high-pressure design, our equipment can complete more efficient solid-liquid separation in a shorter time and significantly reduce the moisture content of the mud cake.

The automated configuration of the equipment also provides support for improving solid-liquid separation efficiency. Our filter press is equipped with multiple functions such as automatic plate pulling, automatic liquid connection, automatic mud unloading, automatic filter cloth washing and PLC automatic control. These automated configurations not only improve the convenience of operation, but also further optimize the solid-liquid separation process. For example, the automatic mud unloading function can ensure that the filter cake is discharged in time after pressing, reducing the residence time of the filter cake on the filter plate, thus reducing the moisture content. The automatic filter cloth washing function reduces the clogging of the filter cloth and improves the overall efficiency and stability of the equipment.

Jiangsu Sudong Chemical Machinery Co., Ltd. insists on providing users with high-quality services, based on user needs, and solving problems for users in a targeted manner.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt