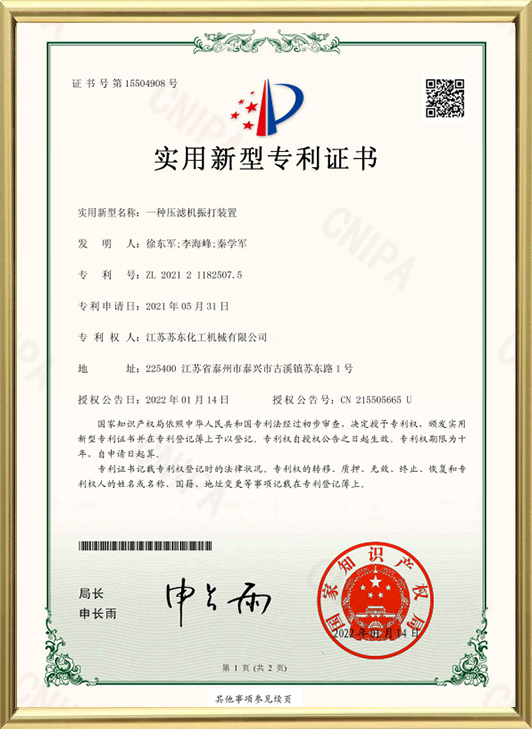

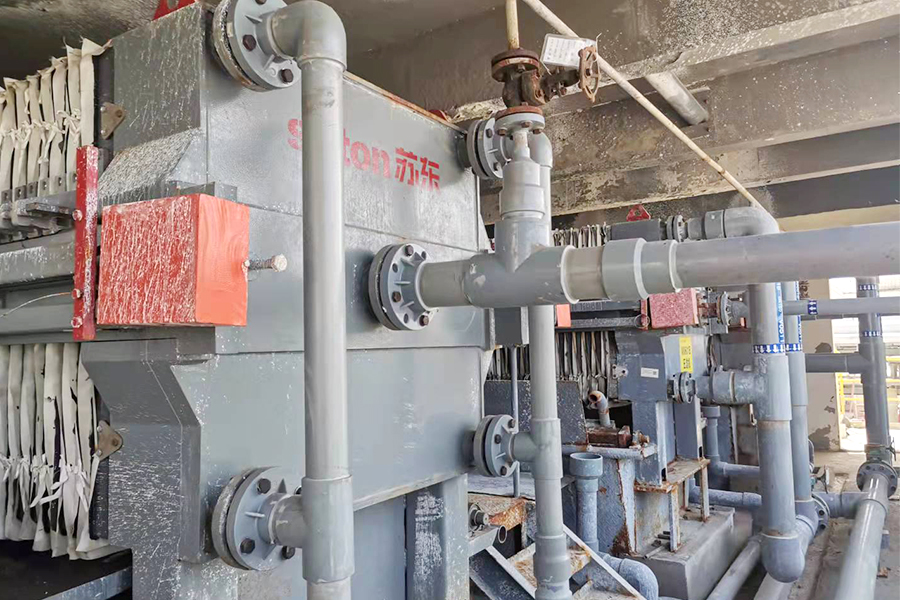

As China Stainless steel filter plate Manufacturers and Stainless steel filter plate Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

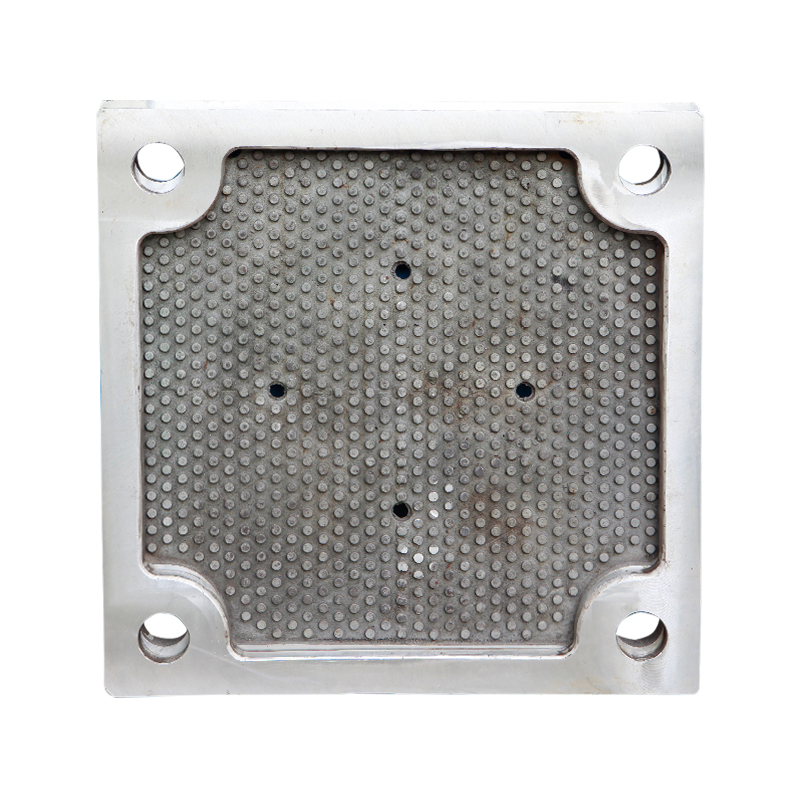

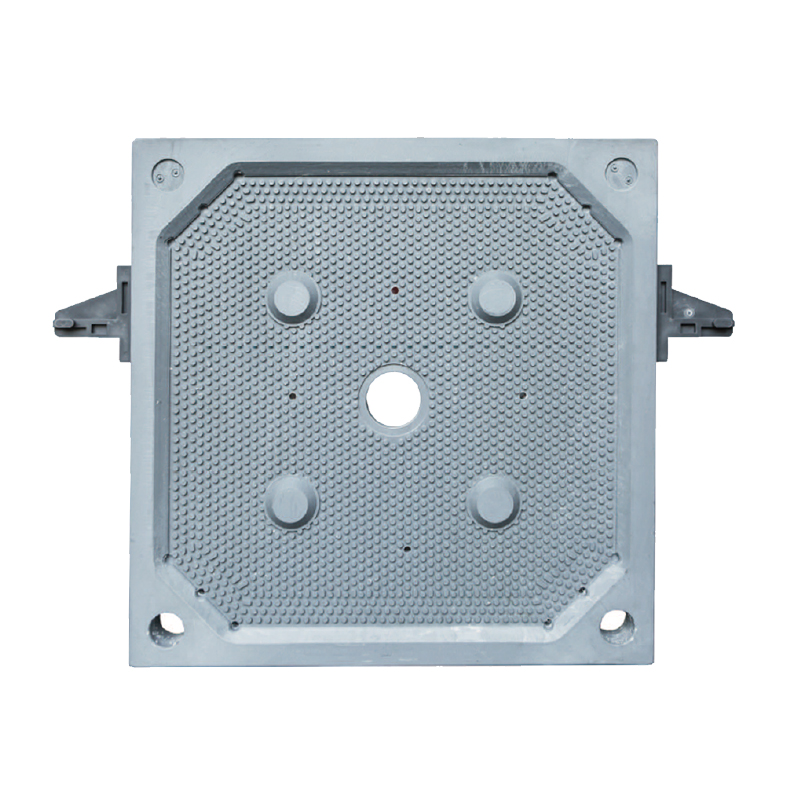

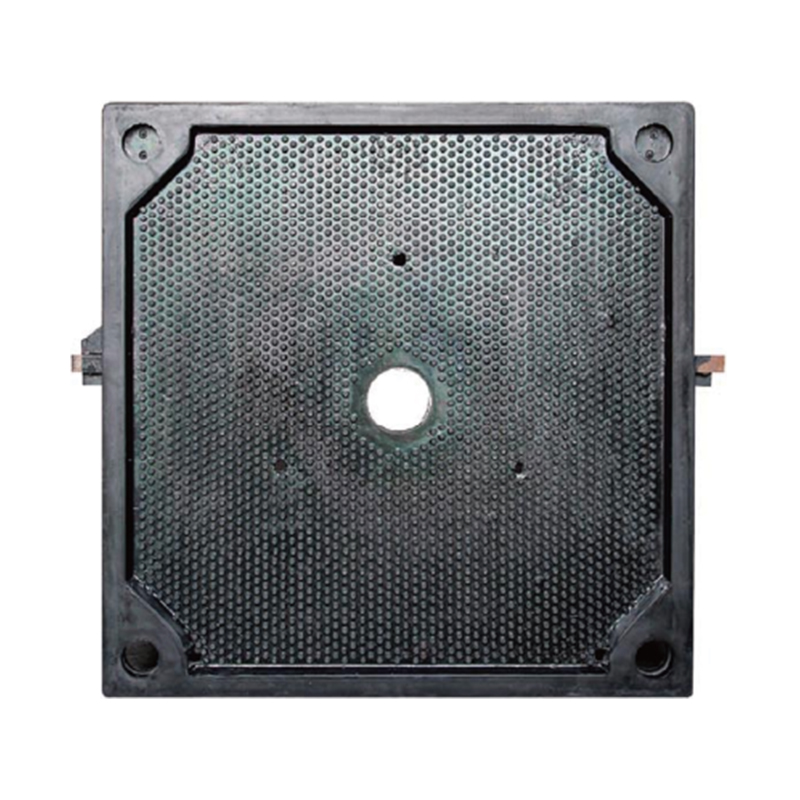

Stainless steel filter plate

Application range: The product has good hygienic performance and is suitable for industries with high hygienic requirements, such as food, medicine, and other fields.

Product features: Stainless steel filter plates play a key role in many industrial filtration processes to ensure the efficient operation of filtration operations.

Product advantages: Strong corrosion resistance: can resist a variety of corrosive media, maintain good performance in harsh environments, and extend service life.

High strength: can withstand greater pressure and mechanical stress to ensure the stability and reliability of the filter press process.

Smooth surface: It is conducive to the shedding and cleaning of filter cakes and reduces the residue of filter cakes.

High-temperature resistance: It can work normally at higher temperatures.

Good reusability: It can be used many times after proper maintenance and treatment.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

Filter presses are essential machines in industries such as wastewater treatment, mining, food proce...

READ MORE -

Filter press plates are critical components used in various industrial applications such as wastewat...

READ MORE -

Proper cleaning and maintenance of filter press cloths are crucial for ensuring optimal filtration p...

READ MORE -

A Diaphragm Filter Press is an advanced type of filtration equipment designed to separate solid part...

READ MORE -

The Chamber Filter Press is a vital piece of equipment in wastewater treatment because of its effici...

READ MORE

What factors affect the corrosion resistance of Stainless Steel Filter Plate?

Jiangsu Sudong Chemical Machinery Co., Ltd. is a professional manufacturer of filter presses in China. We focus on the research and development and innovation of filter press technology, and strive for excellence in every detail of the filtration equipment. Stainless Steel Filter Plate is a member of our product line. It has good corrosion resistance. The following will explore the secrets of the corrosion resistance of stainless steel filter plates and understand the key factors that affect its corrosion resistance.

1. The corrosion resistance of stainless steel filter plates depends on the choice of its material. At Jiangsu Sudong Chemical Machinery Co., Ltd., we are well aware that different types of stainless steel have different corrosion resistance characteristics. When selecting materials, we will carefully select the most suitable stainless steel material according to the specific needs and application scenarios of customers. For example, 304 stainless steel is often used in industries with high hygiene requirements such as food and medicine due to its good corrosion resistance, heat resistance and processing performance; while 316 stainless steel performs well in marine environments or occasions containing highly corrosive media due to its higher resistance to chloride ion corrosion.

2. In addition to material selection, surface treatment technology is also an important means to improve the corrosion resistance of stainless steel filter plates. At Jiangsu Sudong Chemical Machinery Co., Ltd., we use advanced surface treatment technologies, such as pickling passivation and electrolytic polishing, to finely treat stainless steel filter plates. These technologies can remove impurities such as oxide scale and rust on the surface of the material, forming a dense passivation film, effectively isolating the direct contact between the corrosive medium and the substrate, thereby improving the corrosion resistance of the stainless steel filter plate.

3. The corrosion resistance of stainless steel filter plates is also affected by external environmental factors such as medium composition and temperature. Different media have different corrosiveness, such as acidic media, alkaline media, salt solutions, etc., and their corrosion effects on stainless steel are different. As the temperature rises, the corrosiveness of the medium tends to increase, and higher requirements are placed on the corrosion resistance of stainless steel filter plates. When designing and using stainless steel filter plates, we need to fully consider factors such as the composition and temperature of the medium, and select appropriate stainless steel materials and surface treatment technologies to ensure that they can operate stably and for a long time in harsh environments.

4. The structural design and manufacturing process of stainless steel filter plates also have an important impact on their corrosion resistance. Jiangsu Sudong Chemical Machinery Co., Ltd. strives for perfection from structural design to manufacturing process. We use advanced CAD/CAM technology for 3D modeling and simulation analysis to ensure that the structure of the filter plate is reasonable and the force is evenly distributed; at the same time, we introduce internationally advanced production equipment and technology to achieve precision processing and efficient production. These measures not only improve the manufacturing accuracy and surface quality of the stainless steel filter plate, but also enhance the stability and corrosion resistance of its overall structure.

5. Although the stainless steel filter plate has excellent corrosion resistance, regular maintenance and care are still the key to extending its service life. At Sudong Chemical, we provide customers with comprehensive after-sales service and technical support, including equipment installation and commissioning, operation training, regular maintenance, etc. We recommend that customers pay attention to the following points during use: First, regularly check the sealing performance and surface condition of the filter plate to promptly discover and deal with potential problems; second, regularly clean the surface and interior of the filter plate to remove residual filter cake and impurities; third, regularly replace severely worn parts or replace the filter plate as a whole according to the use situation. Through these measures, it can be ensured that the stainless steel filter plate always maintains good working condition and corrosion resistance.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt