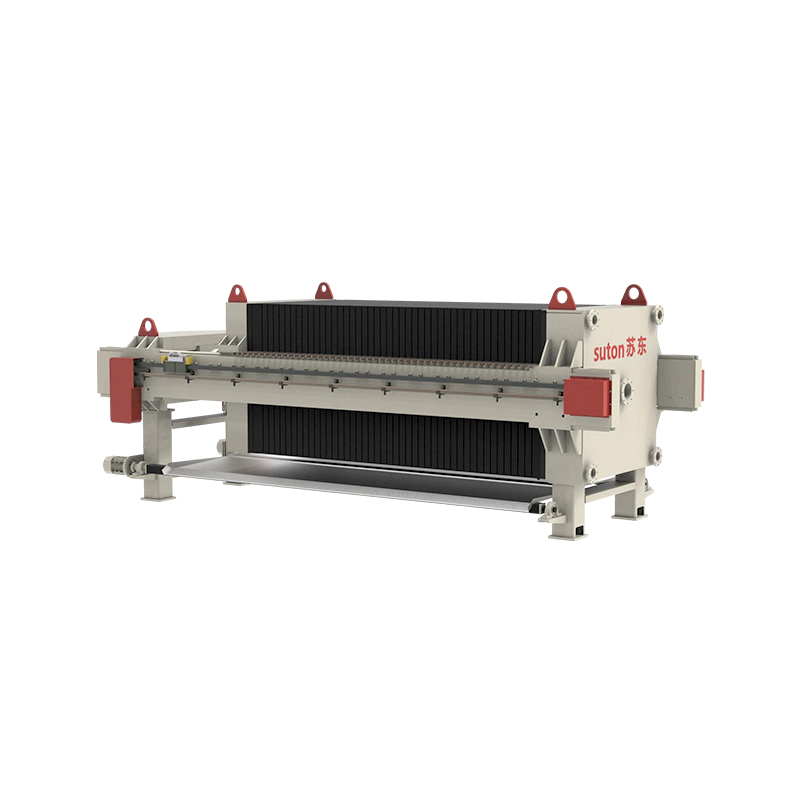

As China Screw stack sludge dewatering machine Manufacturers and Screw stack sludge dewatering machine Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

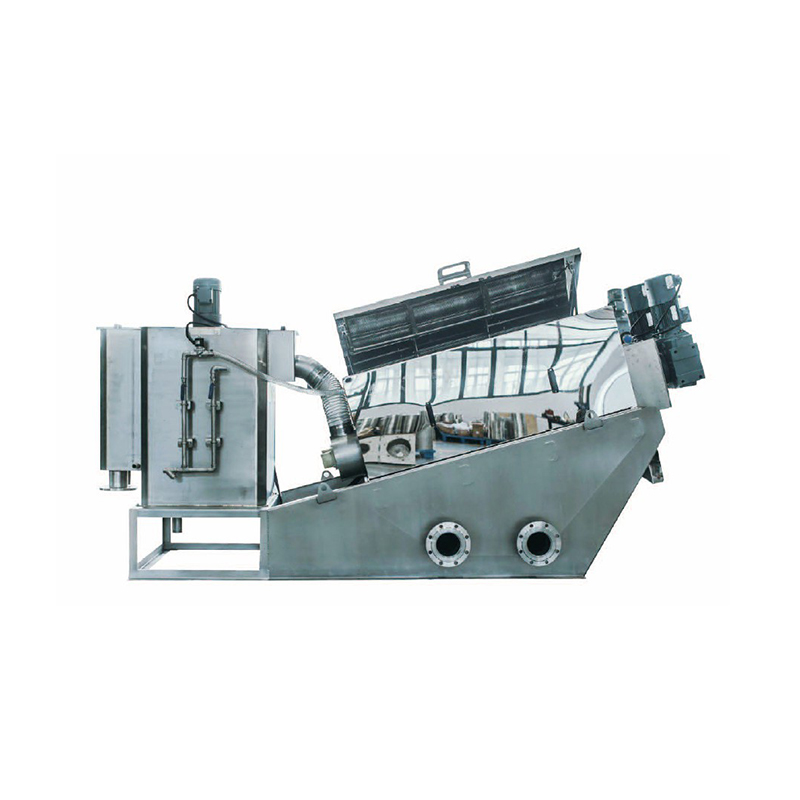

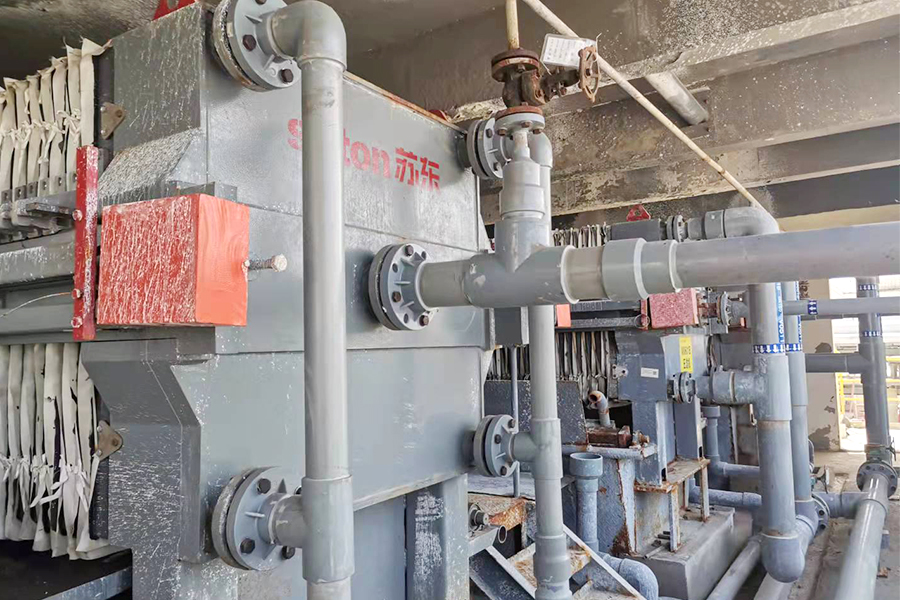

Screw stack sludge dewatering machine

Application range: The spiral stacking sludge dewatering machine is suitable for sludge treatment in municipal sewage, food, beverage, chemical, leather, welding materials, papermaking, printing and dyeing, pharmaceutical and other industries, especially for treating sludge with high oil content.

Product features: low operating costs, low-speed screw extrusion technology, which greatly reduces power consumption; the equipment is not easy to clog, and the flushing water is greatly reduced; 24-hour fully automatic unmanned operation, greatly reducing labor costs.

Product advantages: Under the same processing capacity, the water consumption of the screw stacking machine is only about 1/80 of that of the belt machine; the power consumption of the screw stacking machine is only about 1/12 of that of the centrifuge. Continuous automatic operation, the screw stacking sludge dewatering machine adopts automatic control from pumping sludge, adding liquid medicine, and discharging mud cakes. It is linked through the electric control cabinet, dosing device, mud inlet pump, dosing pump, etc., and can achieve 24-hour unmanned operation.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

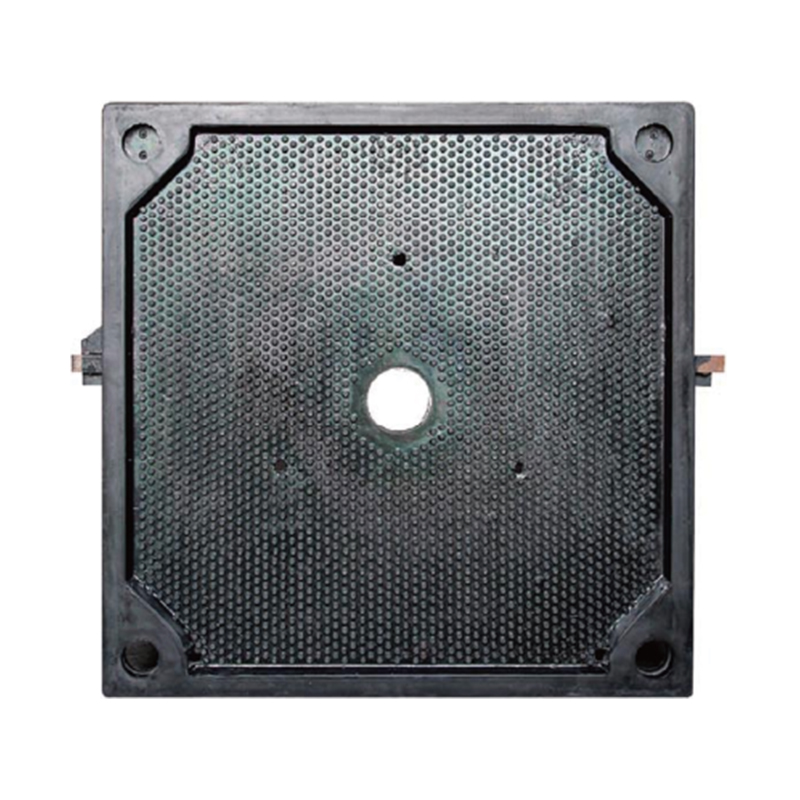

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

Screw stack sludge dewatering machine high-efficiency screw extrusion technology and fast-acting energy-saving effect

In the field of environmental protection technology, sludge treatment has always been an important and complex task. It is not only related to the protection of the ecological environment, but also directly affects the operating costs and sustainable development of enterprises. High-efficiency screw extrusion technology is the core of screw stack sludge dewatering machine. This technology achieves efficient dewatering of sludge through the precisely designed screw shaft and laminated filter structure. During the slow and steady rotation of the screw shaft, the screw shaft exerts a gradually increasing extrusion force on the sludge, forcing the water in the sludge to be discharged through the tiny gaps between the laminates. This design not only makes full use of the principle of physical extrusion, but also realizes the continuous transportation and gradual dehydration of sludge through the change of the spiral angle of the screw shaft, greatly improving the dehydration efficiency.

Screw stack sludge dewatering machine also puts a lot of effort in the selection of screw shaft and laminated materials. Made of high-strength and corrosion-resistant materials, it ensures the stable operation and long service life of the equipment under harsh working conditions. At the same time, by optimizing the structure of the screw shaft and the arrangement of the stacked sheets, the dewatering effect is further improved, and the moisture content of the treated sludge is significantly reduced.

Energy saving and consumption reduction is one of the important directions of current environmental protection equipment research and development. The screw stack sludge dewatering machine also performs well in energy saving. Its low-speed, high-torque screw extrusion technology itself has low energy consumption characteristics. Compared with traditional centrifuges and belt filter presses, the equipment requires less electricity during operation, which greatly reduces the company's electricity bill expenditure.

The fast-acting energy-saving effect is not only reflected in the reduction of energy consumption of the equipment itself, but also in the reduction of the overall cost of the entire sludge treatment system. Due to the characteristics of high dewatering efficiency, short treatment cycle and large treatment volume, the equipment can significantly reduce the storage and transportation costs of sludge, and reduce the energy consumption and costs of subsequent treatment links. At the same time, the moisture content of the dehydrated sludge is reduced, which is conducive to resource utilization or harmless treatment, further improving the economic value and environmental benefits of the sludge.

As an environmental protection technology company integrating R&D, manufacturing and engineering contracting, Sudong always adheres to the customer-centric service concept. For Screw Stack Sludge Dewatering Machine, Sudong provides a full range of customized services, including equipment design, manufacturing, installation, commissioning and post-maintenance according to the specific needs of customers. This customized service not only meets the personalized needs of customers, but also ensures the best operation effect of the equipment at the customer's site.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt