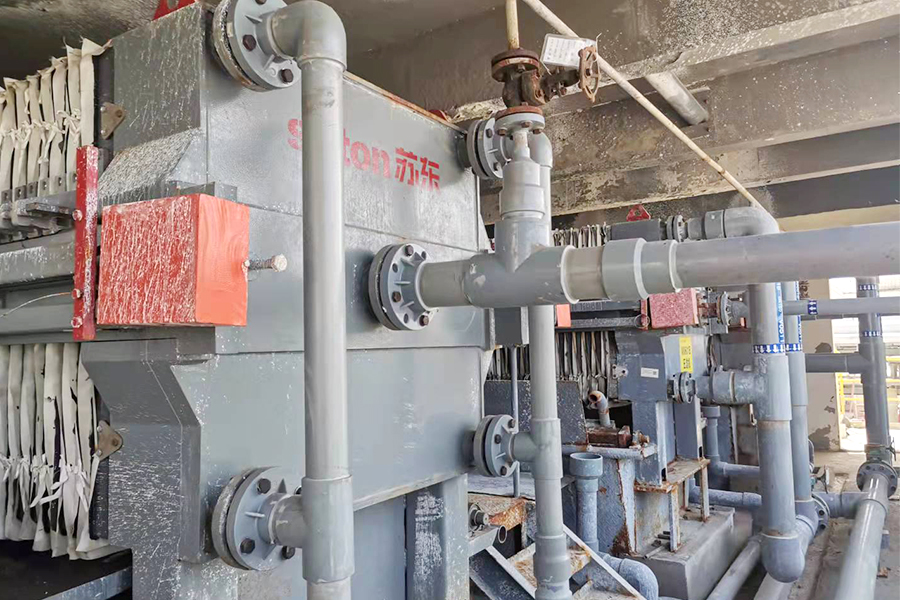

As China Screw conveyor Manufacturers and Screw conveyor Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

Screw conveyor

Product features: The screw conveyor is a common conveying equipment. It is mainly composed of a spiral shaft, spiral blades, a casing, a drive device, etc. Its working principle is to use the rotating spiral blades to push the material forward along the conveying direction.

Product advantages: 1. Simple structure: easy to install and maintain.

2. Good sealing performance: can effectively prevent material leakage and environmental pollution.

3. Strong conveying capacity: can convey a variety of materials of different properties.

4. Long conveying distance: can be arranged at a certain length according to needs.

5. Flexible layout: can be installed horizontally, inclined, or even vertically.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

Screw conveyor flexible installation advantages

The installation method of the screw conveyor directly affects its layout in the production line and the efficiency of the overall system. Jiangsu Sudong Chemical Machinery Co., Ltd. makes full use of its professional experience in mechanical design and manufacturing to provide a variety of flexible installation methods to ensure that the equipment can adapt to various complex process requirements and site conditions.

Horizontal installation

In traditional conveying needs, horizontal installation is the most common method. The screw conveyor can be easily integrated into the existing production line, especially in the process that requires large-scale and continuous conveying of materials. The horizontal installation method can ensure the smooth flow of materials and reduce the wear of the equipment. This method is commonly used in the chemical, food, pharmaceutical and other industries, and has excellent performance when conveying powdered or granular materials.

Tilt installation

The tilt installation method is often used in scenes where materials need to be lifted. The screw conveyor can adjust the tilt angle according to the specific needs of the customer, usually between 0° and 45°. The choice of tilt angle mainly depends on factors such as the fluidity, viscosity and conveying distance of the material. Through the precise tilt angle design, the screw conveyor can effectively prevent the material from sliding or accumulating during the tilting process, ensuring the continuity and stability of the conveying process. This installation method is widely used in fields such as metallurgy, building materials and mining, especially in the transportation of bulk materials such as ore and coal.

Vertical installation

Vertical installation is a special arrangement method suitable for application scenarios where space is limited but a large height is required. Vertical screw conveyors can effectively overcome the backflow and blockage problems that may occur during vertical transportation of materials by optimizing the design and material selection of spiral blades. Vertical installation is common in multi-story production facilities or occasions where materials need to be transported from one production floor to another, such as pharmaceutical plants and food processing plants. Vertical screw conveyors not only take up little space, but are also easy to maintain, making them an ideal choice for efficient use of vertical space.

Combined installation

In complex production systems, it is often necessary to use a combination of multiple installation methods to achieve full process automation from material reception, processing to final output. Screw conveyors can flexibly combine horizontal, inclined and vertical installation methods according to the needs of the production process. This combined installation not only improves the overall efficiency of the system, but also reduces the transportation time and energy consumption of materials between different processes. It is particularly suitable for the complex process requirements of large chemical plants, smelters and water treatment plants.

Modular design

In order to further enhance the installation flexibility of screw conveyors, a modular design concept is adopted. The modular design allows the equipment to be quickly assembled or adjusted according to actual needs at the production site to adapt to different production layouts and process changes. The modular design also facilitates the maintenance and upgrade of the equipment, reducing downtime and maintenance costs. This design advantage is particularly prominent in industries that require frequent adjustments to production processes.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt