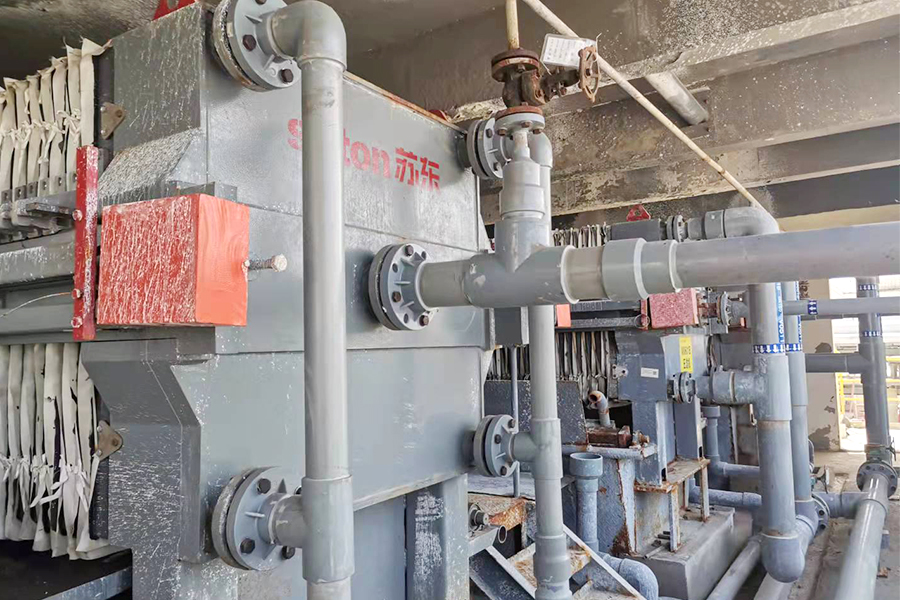

As China Composite rubber plate chamber filter press Manufacturers and Composite rubber plate chamber filter press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

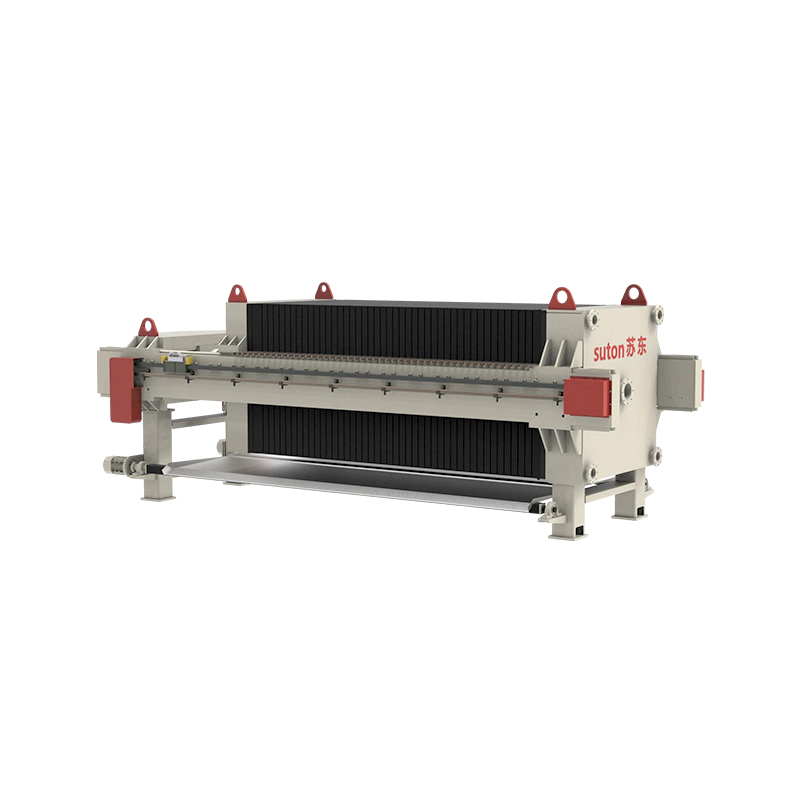

Composite rubber plate chamber filter press

Application range: The product is widely used in solid-liquid separation in petrochemical, non-ferrous metallurgy, fine chemicals, and other industries.

Product features: The machine can be equipped with various configurations such as automatic plate pulling, automatic liquid connection, varicose mud unloading, automatic filter cloth washing, PLC automatic control, etc. The operation panel is simple and safe, and the degree of automation is high.

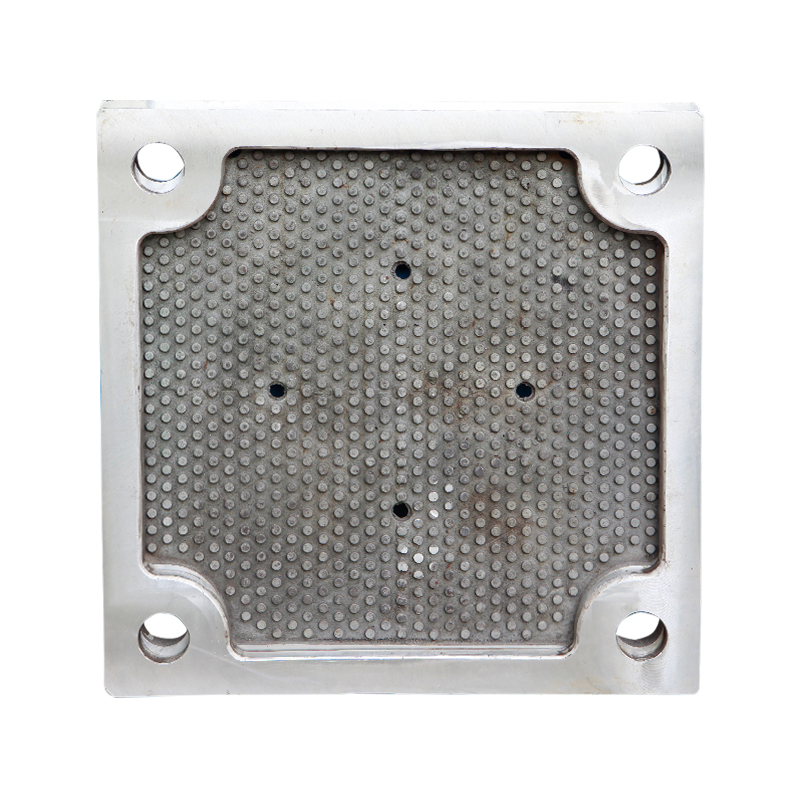

Product advantages: The rubber plate is made of chloroprene rubber (DuPont, USA), which is compounded with the steel skeleton for high-pressure vulcanization after mixing and modification. The filter plate has good sealing performance, the working filtration pressure can reach 1.2MPa, the filter plate has high strength and, a long service life, and the filter plate can withstand a temperature of up to 120℃; the steel skeleton can be recycled multiple times, and the comprehensive maintenance cost is low. The overall frame is made of high-strength steel welded parts, the frame has high strength, stable structure, and long service life.

Product details

| Specification | Number of Filter Plates | Chamber Volume (m³) | Overall Dimensions(mm) | Filter Plate Size(mm) | Filtration Pressure | Matching Power(KW) | Weight Of Single Machine(Kg) |

| FBXY-YZ30/870-U | 23 | 0.45 | 3550×1450×1250 | 870×870×50 | ≤0.8 | 5.5 | 3820 |

| FBXY-YZ40/870-U | 31 | 0.6 | 3950×1450×1250 | 870×870×50 | 4450 | ||

| FBXY-YZ50/870-U | 39 | 0.75 | 4350×1450×1250 | 870×870×50 | 5100 | ||

| FBXY-YZ60/870-U | 47 | 0.9 | 4725×1450×1250 | 870×870×50 | 5340 | ||

| FBXY-YZ70/870-U | 55 | 1.05 | 5150×1450×1250 | 870×870×50 | 6280 | ||

| FBXY-YZ80/870-U | 63 | 1.2 | 5550×1450×1250 | 870×870×50 | 6850 | ||

| FBXY-YZ60/1070-U | 30 | 0.9 | 3950×1580×1440 | 1070×1070×50 | 5.5 | 7050 | |

| FBXY-YZ70/1070-U | 35 | 1.05 | 4200×1580×1440 | 1070×1070×50 | 7750 | ||

| FBXY-YZ80/1070-U | 40 | 1.2 | 4450×1580×1440 | 1070×1070×50 | 8450 | ||

| FBXY-YZ90/1070-U | 45 | 1.35 | 4700×1580×1440 | 1070×1070×50 | 9120 | ||

| FBXY-YZ100/1070-U | 50 | 1.5 | 4950×1580×1440 | 1070×1070×50 | 9800 | ||

| FBXY-YZ110/1070-U | 55 | 1.65 | 5200×1580×1440 | 1070×1070×50 | 10450 | ||

| FBXY-YZ120/1070-U | 60 | 1.8 | 5450×1580×1440 | 1070×1070×50 | 11080 | ||

| FBXY-YZ130/1070-U | 65 | 1.95 | 5700×1580×1440 | 1070×1070×50 | 11700 | ||

| FBXY-YZ140/1070-U | 70 | 2.1 | 5950×1580×1440 | 1070×1070×50 | 12350 | ||

| FBXY-YZ150/1070-U | 75 | 2.25 | 6200×1580×1440 | 1070×1070×50 | 12950 | ||

| FBXY-YZ100/1250 | 37 | 1.5 | 5100×1700×1875 | 1250×1250×55 | ≤0.8 | 5.5 | 10200 |

| FBXY-YZ120/1250 | 45 | 1.8 | 5550×1700×1875 | 1250×1250×55 | 11400 | ||

| FBXY-YZ140/1250 | 51 | 2.1 | 5880×1700×1875 | 1250×1250×55 | 12300 | ||

| FBXY-YZ150/1250 | 55 | 2.25 | 6100×1700×1875 | 1250×1250×55 | 12900 | ||

| FBXY-YZ160/1250 | 59 | 2.4 | 6310×1700×1875 | 1250×1250×55 | 13500 | ||

| FBXY-YZ180/1250 | 67 | 2.7 | 6750×1700×1875 | 1250×1250×55 | 14700 | ||

| FBXY-YZ200/1250 | 75 | 3 | 7190×1700×1875 | 1250×1250×55 | 15900 | ||

| FBXY-YZ200/1360-U-1 | 61 | 3 | 6590×1800×1700 | 1360×1360×55 | ≤0.8 | 5.5 | 19600 |

| FBXY-YZ220/1360-U-1 | 67 | 3.3 | 6930×1800×1700 | 1360×1360×55 | 21400 | ||

| FBXY-YZ250/1360-U-1 | 75 | 3.74 | 7360×1800×1700 | 1360×1360×55 | 23800 | ||

| FBXY-YZ280/1360-U-1 | 85 | 4.2 | 7910×1800×1700 | 1360×1360×55 | 26800 | ||

| FBXY-YZ300/1360-U-1 | 91 | 4.5 | 8240×1800×1700 | 1360×1360×55 | 28600 | ||

| FBXY-YZ340/1360-U-1 | 103 | 5.1 | 8900×1800×1700 | 1360×1360×55 | 32200 | ||

| FBXY-YZ350/1360-U-1 | 107 | 5.25 | 9250×1800×1700 | 1360×1360×55 | 33400 | ||

| FBXY-YZ400/1360-U-1 | 121 | 6 | 10020×1800×1700 | 1360×1360×55 | 37600 | ||

| FBXY-YZ200/1360-U-Ⅱ | 61 | 3.8 | 7200×1800×1700 | 1360×1360×65 | ≤0.8 | 5.5 | 22200 |

| FBXY-YZ220/1360-U-Ⅱ | 67 | 4.1 | 7600×1800×1700 | 1360×1360×65 | 23800 | ||

| FBXY-YZ250/1360-U-Ⅱ | 75 | 4.7 | 8110×1800×1700 | 1360×1360×65 | 25700 | ||

| FBXY-YZ280/1360-U-Ⅱ | 85 | 5.3 | 8760×1800×1700 | 1360×1360×65 | 28300 | ||

| FBXY-YZ300/1360-U-Ⅱ | 91 | 5.7 | 9150×1800×1700 | 1360×1360×65 | 30200 | ||

| FBXY-YZ340/1360-U-Ⅱ | 103 | 6.4 | 9930×1800×1700 | 1360×1360×65 | 33200 | ||

| FBXY-YZ350/1360-U-Ⅱ | 107 | 6.6 | 10320×1800×1700 | 1360×1360×65 | 34000 | ||

| FBXY-YZ400/1360-U-Ⅱ | 121 | 7.6 | 11230×1800×1700 | 1360×1360×65 | 37600 | ||

| FBXY-YZ 200/1500 | 51 | 3.8 | 6740×2050×1760 | 1500×1500×65 | ≤0.8 | 8 | 26500 |

| FBXY-YZ 220/1500 | 55 | 4.1 | 7000×2050×1760 | 1500×1500×65 | 28200 | ||

| FBXY-YZ 250/1500 | 63 | 4.7 | 7520×2050×1760 | 1500×1500×65 | 31250 | ||

| FBXY-YZ 280/1500 | 71 | 5.3 | 8040×2050×1760 | 1500×1500×65 | 34300 | ||

| FBXY-YZ 300/1500 | 75 | 5.7 | 8300×2050×1760 | 1500×1500×65 | 35900 | ||

| FBXZ-YZ 320/1500 | 81 | 6 | 8690×2050×1760 | 1500×1500×65 | 37640 | ||

| FBXZ-YZ 340/1500 | 87 | 6.4 | 9080×2050×1760 | 1500×1500×65 | 39560 | ||

| FBXZ-YZ 400/1500 | 101 | 7.6 | 9990×2050×1760 | 1500×1500×65 | 44230 | ||

| FBXZ-YZ 450/1500 | 115 | 8.5 | 10900×2050×1760 | 1500×1500×65 | 48520 | ||

| FBXZ-YZ 500/1500 | 127 | 9.5 | 11680×2050×1760 | 1500×1500×65 | 51360 | ||

| FBXZ-YZ 560/1500 | 143 | 10.6 | 12720×2050×1760 | 1500×1500×65 | 57480 | ||

| FBXY-YZ 400/1800 | 69 | 7.6 | 8085×2300×2100 | 1800×1800×65 | ≤0.8 | 8 | 47600 |

| FBXY-YZ 450/1800 | 77 | 8.5 | 8605×2300×2100 | 1800×1800×65 | 51900 | ||

| FBXY-YZ 500/1800 | 87 | 9.5 | 9255×2300×2100 | 1800×1800×65 | 57000 | ||

| FBXY-YZ 560/1800 | 97 | 10.6 | 9905×2300×2100 | 1800×1800×65 | 63200 | ||

| FBXY-YZ 600/1800 | 103 | 11.4 | 10295×2300×2100 | 1800×1800×65 | 64790 | ||

| FBXZ-YZ 630/1800 | 109 | 11.9 | 10685×2300×2100 | 1800×1800×65 | 67400 | ||

| FBXZ-YZ 700/1800 | 121 | 13.3 | 11465×2300×2100 | 1800×1800×65 | 73800 | ||

| FBXZ-YZ 750/1800 | 129 | 14 | 11855×2300×2100 | 1800×1800×65 | 77500 | ||

| FBXZ-YZ 800/1800 | 139 | 15.2 | 12635×2300×2100 | 1800×1800×65 | 82500 | ||

| FBXZ-YZ 900/1800 | 157 | 17 | 13805×2300×2100 | 1800×1800×65 | 93700 | ||

| FBXZ-YZ 1000/1800 | 175 | 19 | 14975×2300×2100 | 1800×1800×65 | 96000 | ||

| FBXZ-YZ 1100/1800 | 191 | 20.9 | 16015×2300×2100 | 1800×1800×65 | 105800 | ||

| FBXZ-YZ 1200/1800 | 209 | 22.8 | 17185×2300×2100 | 1800×1800×65 | 118600 |

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

How does the varicose discharge function achieve automatic unloading of filter cake?

The varicose discharge function is an important technical innovation in the Composite Rubber Plate Chamber Filter Press. It realizes automatic unloading of filter cake through varicose movement. This function plays a vital role in improving the automation and operating efficiency of the filter press. As a professional manufacturer, we are well aware that in the solid-liquid separation process, the unloading process of the filter cake is often the bottleneck of the entire operation. If the filter cake cannot be unloaded efficiently and quickly, it will directly affect the overall working efficiency of the equipment.

The varicose discharge function uses a special mechanical design and movement method to make the filter plate perform a certain varicose movement while opening. The vibration and mechanical force generated by this movement can effectively separate the filter cake attached to the filter cloth and make it fall off naturally. Traditional filter presses usually rely on manual or simple mechanical methods to unload the filter cake, which is not only time-consuming, but may also cause wear of the filter cloth, thereby increasing maintenance costs and operating difficulties. The varicose discharge function achieves efficient and lossless unloading of the filter cake through automated mechanical control, greatly shortening the time of each working cycle.

In actual operation, the varicose discharge function has shown significant efficiency advantages. Automated discharge reduces the need for manual intervention, and operators do not need to frequently contact the equipment, reducing labor intensity and labor costs. Secondly, since the filter cake can fall off quickly, the filter press can enter the next filtration cycle faster, improving the overall processing capacity of the equipment. Under high-load and continuous operation conditions, the advantages of the varicose discharge function are more obvious. It can effectively avoid downtime caused by filter cake adhesion, thereby ensuring the continuity and stability of production.

We always adhere to technological innovation and product optimization. The varicose discharge function is one of the results of our years of focused research and development. It has been widely recognized and praised in applications in various industries. Relying on our advanced R&D team and strong manufacturing capabilities, we continuously improve the design and performance of the equipment to meet the growing needs of customers.

In the manufacturing process of the equipment, Sudong Chemical Machinery Co., Ltd. uses high-strength steel welded parts as the frame body to ensure the structural stability of the equipment under long-term high-intensity operation. At the same time, the chloroprene rubber filter plate we selected has been modified by DuPont materials in the United States, and has excellent temperature resistance, corrosion resistance and high strength, so that the filter plate can still maintain good sealing performance under high pressure, extending the service life of the equipment. These high-quality materials and strict manufacturing processes ensure the reliability and efficiency of the varicose discharge function, and can operate stably even under harsh working conditions.

We are well aware that different industries have different requirements for filter presses, so the equipment we provide is highly customizable, including automatic plate pulling, automatic liquid connection, PLC automatic control and other configurations to ensure that the equipment can achieve the best performance in the specific application of customers. Our equipment has been widely used in petrochemical, non-ferrous metallurgy, fine chemicals and other industries, and has received good market feedback in many countries and regions.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt