As China Belt conveyor Manufacturers and Belt conveyor Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

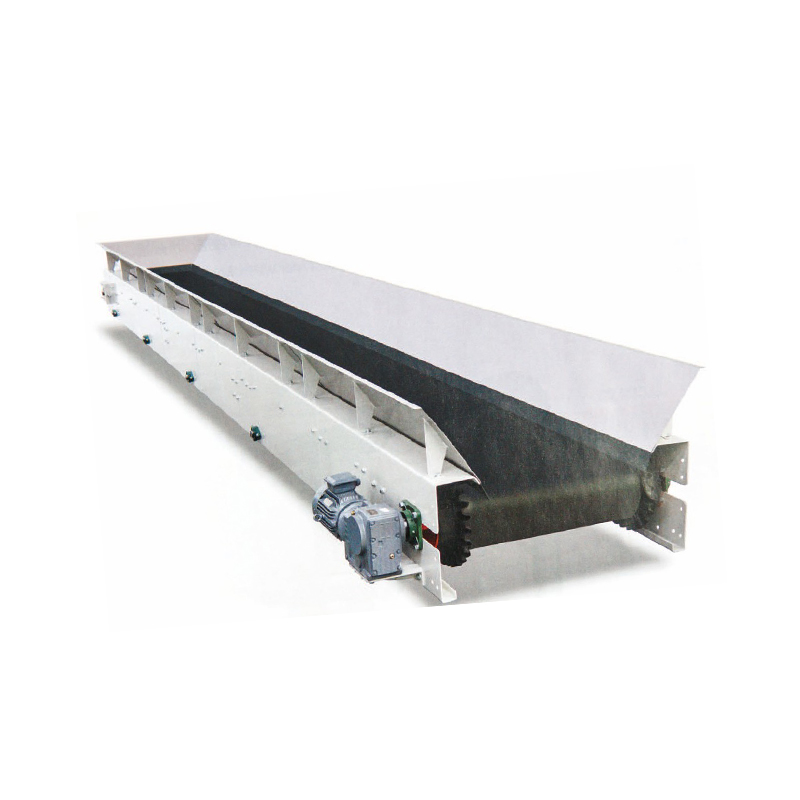

Belt conveyor

Application range: Belt conveyors can be divided into heavy-duty belt conveyors and light-duty belt conveyors according to their uses. Heavy-duty belt conveyors are mainly used in the sludge dewatering industry.

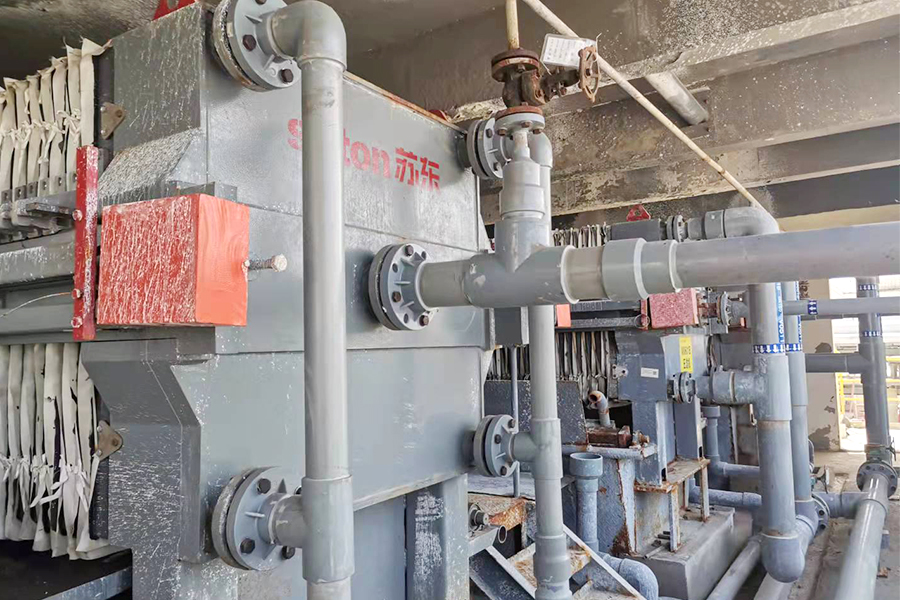

Product features: The horizontal conveyor is placed at the bottom of the filter press. By using a load-bearing crossbeam, adding a mud guide device and heavy-duty legs, the filter press can be placed directly on the conveyor

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

The advantages and diversified configurations of the belt conveyor's stable and durable structure

The belt conveyor uses high-quality materials such as high-strength steel, wear-resistant alloys and high-performance polymers in its structural design to ensure the overall rigidity and durability of the equipment. These materials can withstand high loads and various stresses in long-term operation, reduce deformation and wear of the equipment, and extend the service life of the equipment.

Optimized structural design

The structural design of the belt conveyor has undergone rigorous finite element analysis (FEA) to ensure stability under various operating conditions. The load distribution of the transmission components, support frame and load-bearing parts was considered during the design process to minimize stress concentration during operation and improve overall durability.

Corrosion and wear resistance

For highly corrosive working environments such as sludge dewatering and chemical industry, the key components of the belt conveyor, such as conveyor belts, rollers and brackets, have been treated with anti-corrosion or corrosion-resistant materials have been selected. In addition, a special wear-resistant coating is used on the surface of the conveyor belt to reduce friction loss with the conveyed material and further improve the service life of the equipment.

Reliable transmission system

The transmission system of the belt conveyor is precisely designed. Jiangsu Sudong Chemical Machinery Co., Ltd. uses high-quality reducers, bearings, chains and other key components to ensure long-term smooth operation and reliability. The transmission system has been rigorously tested and optimized, has high fatigue strength and impact resistance, and can maintain continuous and stable operation under high load.

Professional expansion of diversified configurations

Jiangsu Sudong Chemical Machinery Co., Ltd. adopts a modular design concept, allowing customers to flexibly configure according to different process requirements. For example, suitable conveyor belt materials and structural types can be selected according to the characteristics of the conveyed materials, such as high temperature resistant, acid and alkali resistant or anti-slip conveyor belts. This modular design not only simplifies the customization process of the equipment, but also improves the convenience of on-site installation and maintenance.

Multiple conveying forms

The belt conveyor can be configured into a variety of conveying forms, such as horizontal conveying, inclined conveying and vertical conveying, to meet different process requirements. For example, in the sludge dewatering process, the commonly used horizontal conveying and inclined conveying can be adjusted at different angles to ensure smooth material transfer and optimization of dewatering effect.

Multiple specifications and sizes

The configuration of the belt conveyor is not only reflected in the functional modules, but also includes a variety of specifications and sizes to meet the requirements of different sites and working conditions.

Diversity of auxiliary devices

In order to improve the functionality and adaptability of the belt conveyor, a variety of auxiliary device configurations are available, such as cleaning devices, anti-deviation devices, sprinklers and mud guides. These devices can be installed according to specific working conditions to enhance the operating performance and safety of the equipment in specific occasions. For example, during the sludge conveying process, the mud guide can effectively prevent mud leakage and keep the conveying environment clean.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt