As China Polypropylene plate chamber filter press Manufacturers and Polypropylene plate chamber filter press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

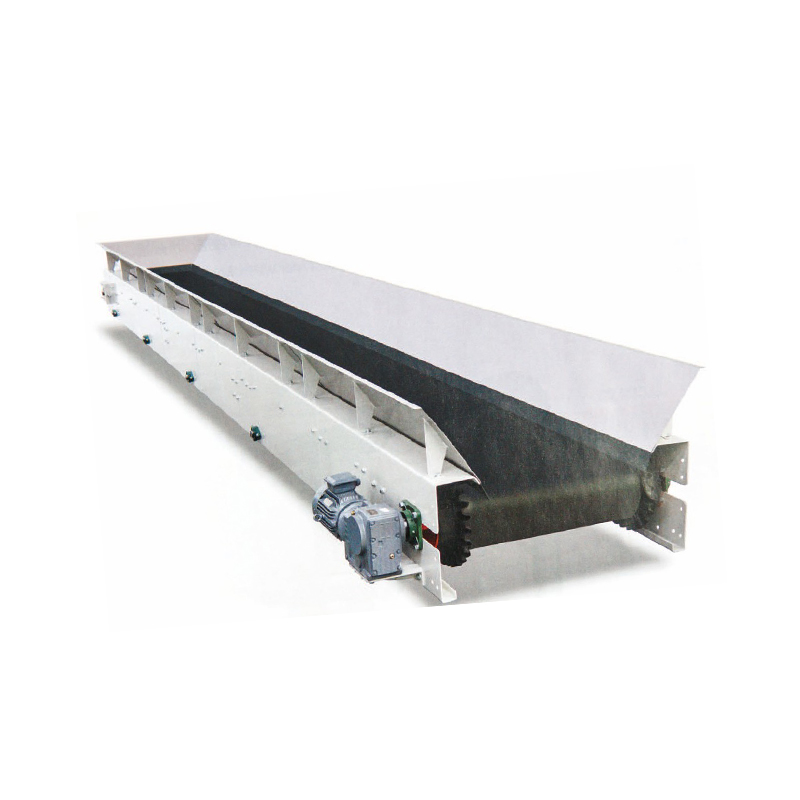

Polypropylene plate chamber filter press

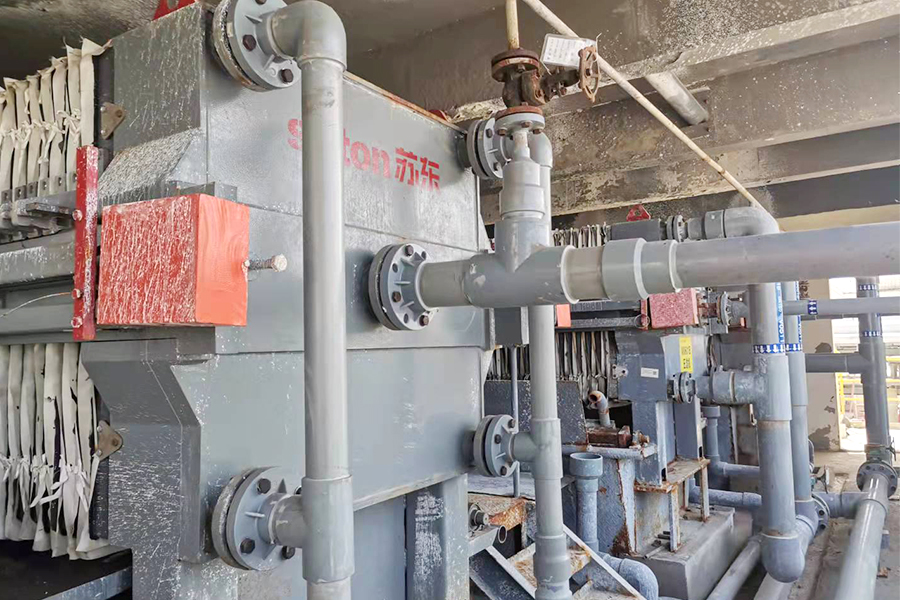

Application range: The product is widely used in solid-liquid separation in petrochemical, nonferrous metallurgy, food and medicine, textile printing and dyeing, fine chemicals, coal dressing, waste power generation, and other industries

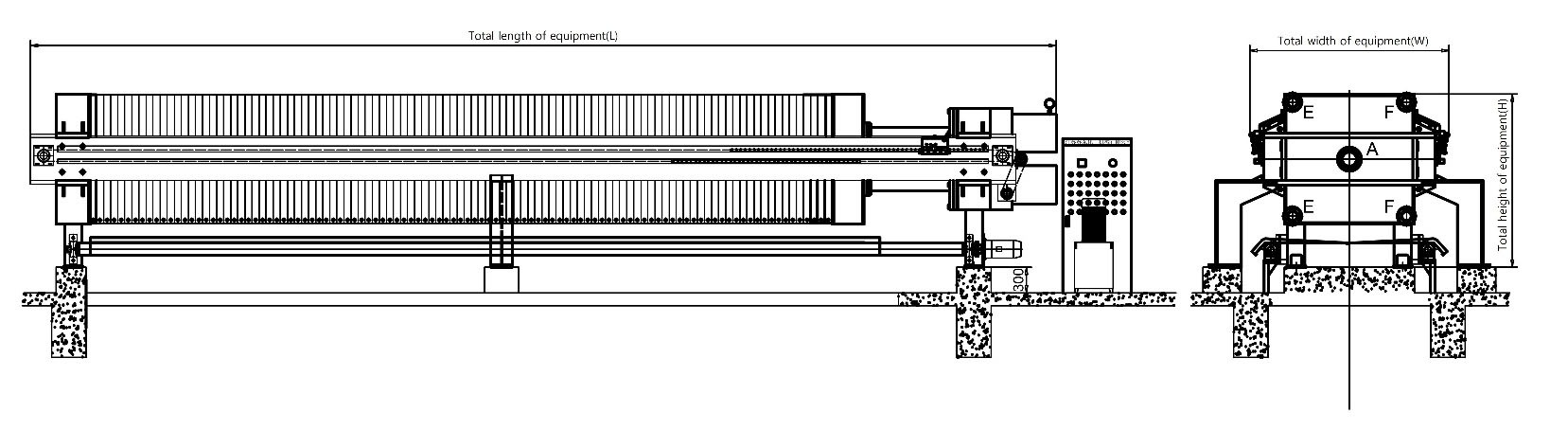

Product features: The machine can be equipped with automatic plate pulling, automatic liquid connection, varicose unloading, automatic filter cloth washing, PLC automatic control, and other configurations. The operation panel is simple and safe, and the degree of automation is high.

Product advantages: The polypropylene plate filter plate is reinforced and modified with high-quality alkali-free glass fiber polypropylene material. The working filtration pressure can reach 1.2MPa, and the filter plate temperature resistance can reach 120℃. It is molded using multiple patented technologies. The surface is flat and smooth, high strength, lightweight, acid and alkali, and corrosion resistance. The frame is made of high-strength steel welded parts, with high frame strength, stable structure, and long service life.

Product details

| Specification | Number of Filter Plate | Chamber Volume(m³) | Overall Dimensions(mm) | Filter Plate Size(mm) | Filtration Pressure(MPa) | Matching Power(KW) | Individual Weight(Kg) | |

| XAMYZ5/600-U | 9 | 0.075 | 2110×1050×1030 | 600×600×60 | ≤0.8 | 1.5 | 1200 | |

| XAMYZ10/600-U | 18 | 0.15 | 2650×1050×1030 | 600×600×60 | 1400 | |||

| XAMYZ12/600-U | 22 | 0.18 | 2930×1050×1030 | 600×600×60 | 1430 | |||

| XAMYZ15/600-U | 27 | 0.225 | 3230×1050×1030 | 600×600×60 | 1530 | |||

| XAMYZ20/600-U | 36 | 0.3 | 4440×1050×1030 | 600×600×60 | 1650 | |||

| XAMYZ25/600-U | 45 | 0.375 | 4560×1050×1030 | 600×600×60 | 1900 | |||

| XAMYZ30/870-U | 23 | 0.45 | 3200×1350×1240 | 870×870×60 | 4 | 2850 | ||

| XAMYZ40/870-U | 31 | 0.6 | 3700×1350×1240 | 870×870×60 | 3200 | |||

| XAMYZ50/870-U | 39 | 0.75 | 4200×1350×1240 | 870×870×60 | 3550 | |||

| XAMYZ54/870-U | 42 | 0.81 | 4380×1350×1240 | 870×870×60 | 3680 | |||

| XAMYZ60/870-U | 47 | 0.9 | 4700×1350×1240 | 870×870×60 | 3900 | |||

| XAMYZ70/870-U | 55 | 1.05 | 5200×1350×1240 | 870×870×60 | 4250 | |||

| XAMYZ80/870-U | 63 | 1.2 | 5700×1350×1240 | 870×870×60 | 4600 | |||

| XAMYZ40/1000-U | 23 | 0.6 | 3300×1500×1600 | 1000×1000×60 | ≤0.8 | 4 | 3970 | |

| XAMYZ50/1000-U | 29 | 0.75 | 4080×1500×1600 | 1000×1000×60 | 4350 | |||

| XAMYZ60/1000-U | 35 | 0.9 | 4440×1500×1600 | 1000×1000×60 | 4600 | |||

| XAMYZ70/1000-U | 41 | 1.05 | 4800×1500×1600 | 1000×1000×60 | 5080 | |||

| XAMYZ80/1000-U | 47 | 1.2 | 5160×1500×1600 | 1000×1000×60 | 5400 | |||

| XAMYZ90/1000-U | 53 | 1.35 | 5520×1500×1600 | 1000×1000×60 | 5700 | |||

| XAMYZ100/1000-U | 59 | 1.5 | 5880×1500×1600 | 1000×1000×60 | 6000 | |||

| XAMYZ110/1000-U | 65 | 1.65 | 6240×1500×1600 | 1000×1000×60 | 6350 | |||

| XAMYZ120/1000-U | 71 | 1.8 | 6600×1500×1600 | 1000×1000×60 | 6700 | |||

| XAMYZ80/1070-U | 40 | 1.2 | 4950×1580×1600 | 1070×1070×60 | 5300 | |||

| XAMYZ90/1070-U | 45 | 1.35 | 5250×1580×1600 | 1070×1070×60 | 5610 | |||

| XAMYZ100/1070-U | 50 | 1.5 | 5550×1580×1600 | 1070×1070×60 | 5890 | |||

| XAMYZ110/1070-U | 55 | 1.65 | 5850×1580×1600 | 1070×1070×60 | 6200 | |||

| XAMYZ120/1070-U | 60 | 1.8 | 6150×1580×1600 | 1070×1070×60 | 6420 | |||

| XAMYZ130/1070-U | 65 | 1.95 | 6450×1580×1600 | 1070×1070×60 | 6690 | |||

| XAMYZ140/1070-U | 70 | 2.1 | 6750×1580×1600 | 1070×1070×60 | 6960 | |||

| XAMYZ150/1070-U | 75 | 2.25 | 7050×1580×1600 | 1070×1070×60 | 7200 | |||

| XAMYZ100/1250-U | 37 | 1.5 | 5100×1700×1875 | 1250×1250×65 | ≤0.8 | 5.5 | 6700 | |

| XAMYZ120/1250-U | 45 | 1.8 | 5620×1700×1875 | 1250×1250×65 | 7100 | |||

| XAMYZ140/1250-U | 51 | 2.1 | 6010×1700×1875 | 1250×1250×65 | 7800 | |||

| XAMYZ150/1250-U | 55 | 2.25 | 6300×1700×1875 | 1250×1250×65 | 8100 | |||

| XAMYZ160/1250-U | 59 | 2.4 | 6550×1700×1875 | 1250×1250×65 | 8400 | |||

| XAMYZ180/1250-U | 67 | 2.7 | 7070×1700×1875 | 1250×1250×65 | 9100 | |||

| XAMYZ200/1250-U | 75 | 3 | 7590×1700×1875 | 1250×1250×65 | 9650 | |||

| XAMYZ250/1250-U | 93 | 3.75 | 8760×1700×1875 | 1250×1250×65 | 11100 | |||

| XAMYZ280/1250-U | 103 | 4.2 | 9410×1700×1875 | 1250×1250×65 | 11800 | |||

| XAMYZ300/1250-U | 111 | 4.5 | 9930×1700×1875 | 1250×1250×65 | 12500 | |||

| XAMYZ320/1250-U | 119 | 4.8 | 10410×1700×1875 | 1250×1250×65 | 13100 | |||

| XAMYZ200/1500-U | 51 | 3 | 6640×2000×2020 | 1500×1500×70 | ≤0.8 | 8 | 14500 | |

| XAMYZ220/1500-U | 55 | 3.3 | 6920×2000×2020 | 1500×1500×70 | 15400 | |||

| XAMYZ250/1500-U | 63 | 3.75 | 7480×2000×2020 | 1500×1500×70 | 16300 | |||

| XAMYZ280/1500-U | 71 | 4.2 | 8040×2000×2020 | 1500×1500×70 | 17400 | |||

| XAMYZ300/1500-U | 75 | 4.5 | 8320×2000×2020 | 1500×1500×70 | 18200 | |||

| XAMYZ320/1500-U | 81 | 4.8 | 8740×2000×2020 | 1500×1500×70 | 19000 | |||

| XAMYZ340/1500-U | 87 | 5.1 | 9160×2000×2020 | 1500×1500×70 | 19800 | |||

| XAMYZ400/1500-U | 101 | 6 | 10140×2000×2020 | 1500×1500×70 | 21200 | |||

| XAMYZ450/1500-U | 115 | 6.75 | 11120×2000×2020 | 1500×1500×70 | 23400 | |||

| XAMYZ500/1500-U | 127 | 7.5 | 12260×2000×2020 | 1500×1500×70 | 24800 | |||

| XAMYZ560/1500-U | 143 | 8.4 | 13080×2000×2020 | 1500×1500×70 | 26800 | |||

| XAMYZ400/2000-U | 56 | 7 | 8240×2600×2560 | 2000×2000×80 | ≤0.8 | 8 | 30200 | |

| XAMYZ430/2000-U | 60 | 7.53 | 8560×2600×2560 | 2000×2000×80 | 31200 | |||

| XAMYZ450/2000-U | 64 | 7.9 | 8880×2600×2560 | 2000×2000×80 | 32200 | |||

| XAMYZ500/2000-U | 71 | 8.75 | 9450×2600×2560 | 2000×2000×80 | 34100 | |||

| XAMYZ560/2000-U | 79 | 9.8 | 10250×2600×2560 | 2000×2000×80 | 36180 | |||

| XAMYZ600/2000-U | 85 | 10.5 | 10730×2600×2560 | 2000×2000×80 | 37800 | |||

| XAMYZ630/2000-U | 89 | 11.03 | 10820×2600×2560 | 2000×2000×80 | 38900 | |||

| XAMYZ700/2000-U | 99 | 12.25 | 11620×2600×2560 | 2000×2000×80 | 41500 | |||

| XAMYZ750/2000-U | 107 | 13.13 | 12260×2600×2560 | 2000×2000×80 | 43580 | |||

| XAMYZ800/2000-U | 115 | 14 | 12900×2600×2560 | 2000×2000×80 | 45600 | |||

| XAMYZ900/2000-U | 129 | 15.75 | 14020×2600×2560 | 2000×2000×80 | 49250 | |||

| XAMYZ1000/2000-U | 143 | 17.5 | 15140×2600×2560 | 2000×2000×80 | 52900 | |||

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

The working filtration pressure of the Polypropylene Plate Chamber Filter Press is 1.2 MPa. What are its advantages in practical applications?

As a professional filter press manufacturer with a long history and advanced technology, Jiangsu Sudong Chemical Machinery Co., Ltd. is well aware of the impact of filtration pressure on filter press performance. In our Polypropylene Plate Chamber Filter Press, the working pressure of 1.2 MPa not only ensures the efficiency of the filtration process, but also provides users with a stable and reliable solid-liquid separation solution.

The filtration pressure of 1.2 MPa can already meet common process requirements when handling solid-liquid separation tasks in most industrial applications. This pressure level provides sufficient force to push liquid through the filter plate, effectively separating solid particles. Especially when processing suspensions with moderate viscosity, this pressure can significantly improve filtration efficiency, shorten processing time, and reduce residual liquid in the filter cake. This is crucial for industrial processes that require efficient solid-liquid separation, such as applications in petrochemical, non-ferrous metallurgy, food and medicine.

Our reinforced polypropylene plate filter plate has excellent high pressure resistance due to the use of high-quality alkali-free glass fiber modified polypropylene material. While 1.2 MPa is sufficient for many industrial applications, our equipment is also designed with support for higher pressures in mind. In actual operation, if the customer's process requirements exceed the range of 1.2 MPa, we can customize, design and produce filter plates with higher pressure levels according to specific requirements. Our company's rich experience and technology accumulation in this field enable us to provide customers with high-voltage solutions to ensure that equipment can operate stably under more demanding process conditions.

For process applications that require handling higher pressures, our technical team is able to design and manufacture filter plates that support higher working pressures according to customers' special needs. Our engineers will optimize the material and structure of the filter plate to ensure that the filter plate can still maintain good performance and durability while increasing the working pressure. This flexibility and adaptability enable us to meet the diverse needs of different industrial sectors.

In addition, the high strength and high temperature resistance of reinforced polypropylene filter plates are also key factors in handling high-pressure processes. The filter plate can operate stably under a pressure of 1.2 MPa, and its excellent temperature resistance (up to 120°C) further enhances the stability of the equipment in high temperature environments. For applications that require filtration under high temperature and pressure conditions, our equipment can provide consistent and reliable performance to ensure the smooth progress of the production process.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt