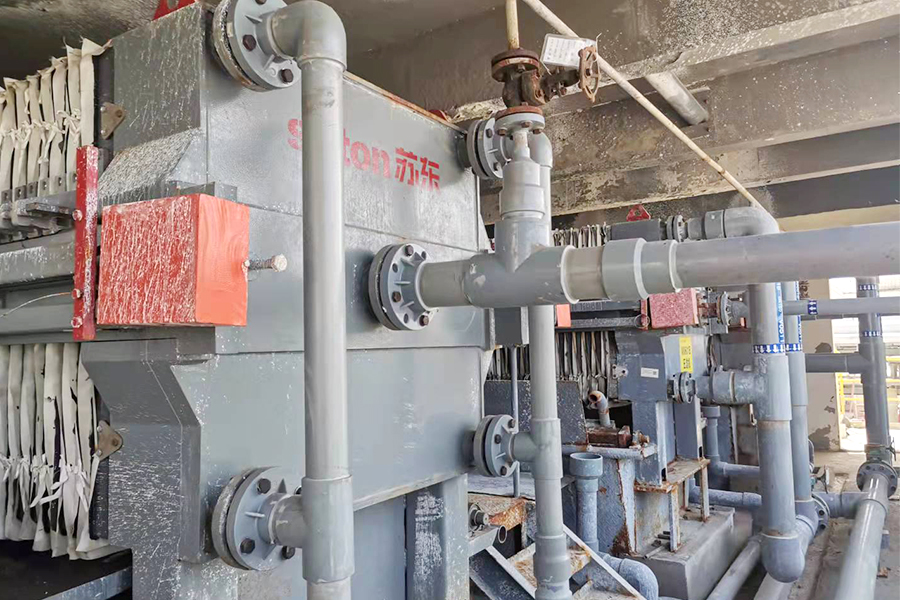

As China Composite rubber plate diaphragm filter press Manufacturers and Composite rubber plate diaphragm filter press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

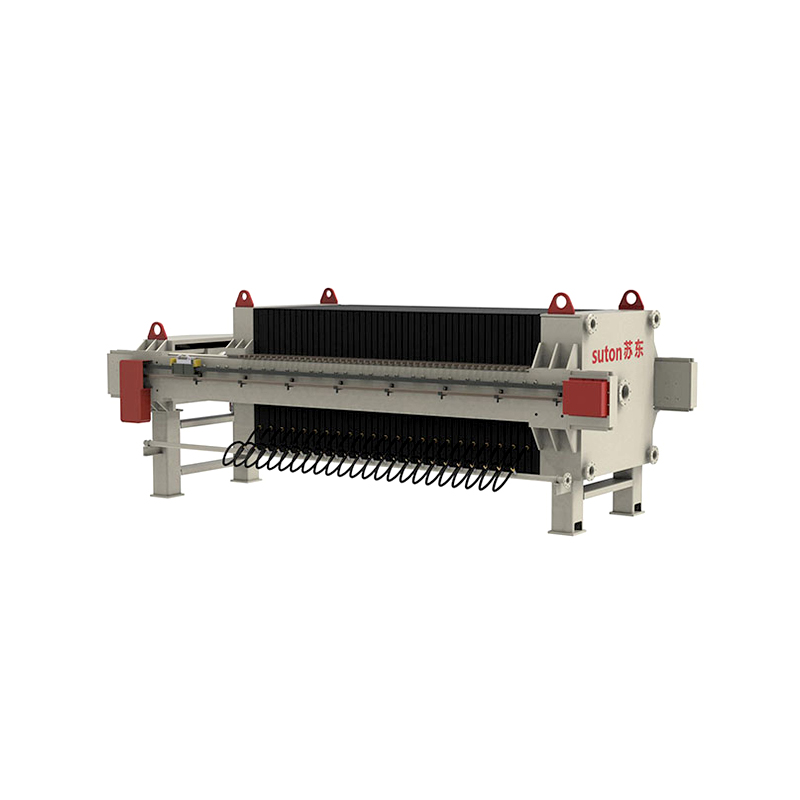

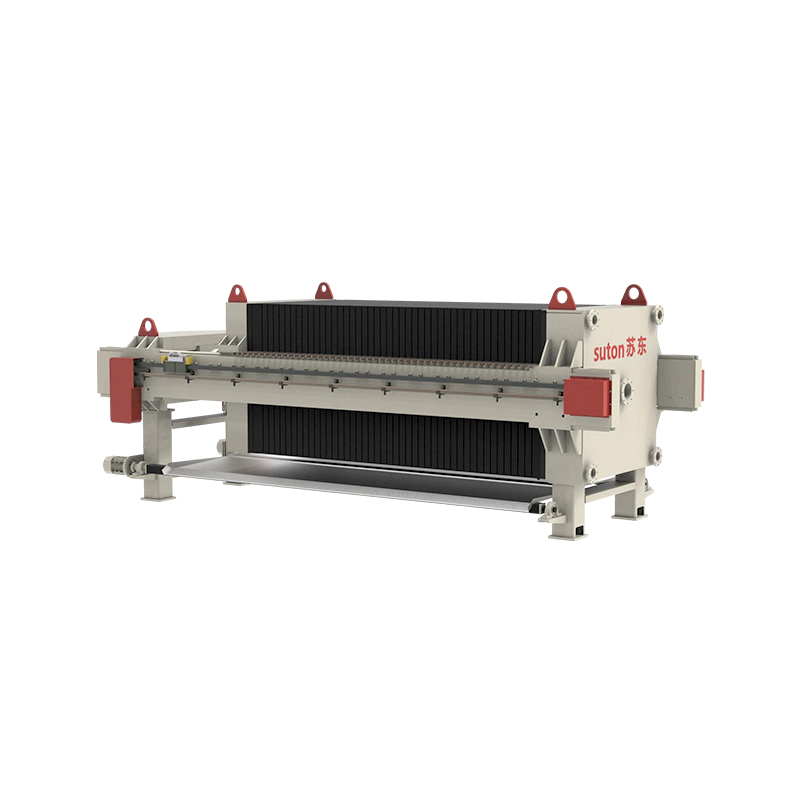

Composite rubber plate diaphragm filter press

Application range: The product is widely used in solid-liquid separation in petrochemical, non-ferrous metallurgy, fine chemical and other industries.

Product features: The machine can be equipped with various configurations such as automatic plate pulling, automatic liquid connection, varicose mud unloading, automatic filter cloth washing, PLC automatic control, etc. The operation panel is simple and safe, and the degree of automation is high.

Product advantages: The composite rubber diaphragm filter plate is made of high-quality chloroprene rubber (DuPont/Chongqing Changshou in the United States), which is compounded and vulcanized with the steel skeleton after mixing and modification. The sealing surface of the filter plate is in elastic contact and has good sealing performance; it adopts full rubber diaphragm plate pressing, the filter cake has low moisture content, the diaphragm pressing pressure can reach 1.6MPa, the processing capacity is large, and the steel skeleton of the filter plate can be recycled for multiple times, with high comprehensive economic benefits. The overall frame is made of high-strength steel welded parts, with high frame strength, stable structure and long service life.

Product details

| Specification | Number of Filter Plates | Chamber Volume (m³) | Overall Dimensions(mm) | Filter Plate Size(mm) | Filtration Pressure | Matching Power(KW) | Weight Of Single Machine(Kg) |

| FBXY-YZ30/870-U | 23 | 0.45 | 3550×1450×1250 | 870×870×50 | ≤0.8 | 5.5 | 3820 |

| FBXY-YZ40/870-U | 31 | 0.6 | 3950×1450×1250 | 870×870×50 | 4450 | ||

| FBXY-YZ50/870-U | 39 | 0.75 | 4350×1450×1250 | 870×870×50 | 5100 | ||

| FBXY-YZ60/870-U | 47 | 0.9 | 4725×1450×1250 | 870×870×50 | 5340 | ||

| FBXY-YZ70/870-U | 55 | 1.05 | 5150×1450×1250 | 870×870×50 | 6280 | ||

| FBXY-YZ80/870-U | 63 | 1.2 | 5550×1450×1250 | 870×870×50 | 6850 | ||

| FBXY-YZ60/1070-U | 30 | 0.9 | 3950×1580×1440 | 1070×1070×50 | 5.5 | 7050 | |

| FBXY-YZ70/1070-U | 35 | 1.05 | 4200×1580×1440 | 1070×1070×50 | 7750 | ||

| FBXY-YZ80/1070-U | 40 | 1.2 | 4450×1580×1440 | 1070×1070×50 | 8450 | ||

| FBXY-YZ90/1070-U | 45 | 1.35 | 4700×1580×1440 | 1070×1070×50 | 9120 | ||

| FBXY-YZ100/1070-U | 50 | 1.5 | 4950×1580×1440 | 1070×1070×50 | 9800 | ||

| FBXY-YZ110/1070-U | 55 | 1.65 | 5200×1580×1440 | 1070×1070×50 | 10450 | ||

| FBXY-YZ120/1070-U | 60 | 1.8 | 5450×1580×1440 | 1070×1070×50 | 11080 | ||

| FBXY-YZ130/1070-U | 65 | 1.95 | 5700×1580×1440 | 1070×1070×50 | 11700 | ||

| FBXY-YZ140/1070-U | 70 | 2.1 | 5950×1580×1440 | 1070×1070×50 | 12350 | ||

| FBXY-YZ150/1070-U | 75 | 2.25 | 6200×1580×1440 | 1070×1070×50 | 12950 | ||

| FBXY-YZ100/1250 | 37 | 1.5 | 5100×1700×1875 | 1250×1250×55 | ≤0.8 | 5.5 | 10200 |

| FBXY-YZ120/1250 | 45 | 1.8 | 5550×1700×1875 | 1250×1250×55 | 11400 | ||

| FBXY-YZ140/1250 | 51 | 2.1 | 5880×1700×1875 | 1250×1250×55 | 12300 | ||

| FBXY-YZ150/1250 | 55 | 2.25 | 6100×1700×1875 | 1250×1250×55 | 12900 | ||

| FBXY-YZ160/1250 | 59 | 2.4 | 6310×1700×1875 | 1250×1250×55 | 13500 | ||

| FBXY-YZ180/1250 | 67 | 2.7 | 6750×1700×1875 | 1250×1250×55 | 14700 | ||

| FBXY-YZ200/1250 | 75 | 3 | 7190×1700×1875 | 1250×1250×55 | 15900 | ||

| FBXY-YZ200/1360-U-1 | 61 | 3 | 6590×1800×1700 | 1360×1360×55 | ≤0.8 | 5.5 | 19600 |

| FBXY-YZ220/1360-U-1 | 67 | 3.3 | 6930×1800×1700 | 1360×1360×55 | 21400 | ||

| FBXY-YZ250/1360-U-1 | 75 | 3.74 | 7360×1800×1700 | 1360×1360×55 | 23800 | ||

| FBXY-YZ280/1360-U-1 | 85 | 4.2 | 7910×1800×1700 | 1360×1360×55 | 26800 | ||

| FBXY-YZ300/1360-U-1 | 91 | 4.5 | 8240×1800×1700 | 1360×1360×55 | 28600 | ||

| FBXY-YZ340/1360-U-1 | 103 | 5.1 | 8900×1800×1700 | 1360×1360×55 | 32200 | ||

| FBXY-YZ350/1360-U-1 | 107 | 5.25 | 9250×1800×1700 | 1360×1360×55 | 33400 | ||

| FBXY-YZ400/1360-U-1 | 121 | 6 | 10020×1800×1700 | 1360×1360×55 | 37600 | ||

| FBXY-YZ200/1360-U-Ⅱ | 61 | 3.8 | 7200×1800×1700 | 1360×1360×65 | ≤0.8 | 5.5 | 22200 |

| FBXY-YZ220/1360-U-Ⅱ | 67 | 4.1 | 7600×1800×1700 | 1360×1360×65 | 23800 | ||

| FBXY-YZ250/1360-U-Ⅱ | 75 | 4.7 | 8110×1800×1700 | 1360×1360×65 | 25700 | ||

| FBXY-YZ280/1360-U-Ⅱ | 85 | 5.3 | 8760×1800×1700 | 1360×1360×65 | 28300 | ||

| FBXY-YZ300/1360-U-Ⅱ | 91 | 5.7 | 9150×1800×1700 | 1360×1360×65 | 30200 | ||

| FBXY-YZ340/1360-U-Ⅱ | 103 | 6.4 | 9930×1800×1700 | 1360×1360×65 | 33200 | ||

| FBXY-YZ350/1360-U-Ⅱ | 107 | 6.6 | 10320×1800×1700 | 1360×1360×65 | 34000 | ||

| FBXY-YZ400/1360-U-Ⅱ | 121 | 7.6 | 11230×1800×1700 | 1360×1360×65 | 37600 | ||

| FBXY-YZ 200/1500 | 51 | 3.8 | 6740×2050×1760 | 1500×1500×65 | ≤0.8 | 8 | 26500 |

| FBXY-YZ 220/1500 | 55 | 4.1 | 7000×2050×1760 | 1500×1500×65 | 28200 | ||

| FBXY-YZ 250/1500 | 63 | 4.7 | 7520×2050×1760 | 1500×1500×65 | 31250 | ||

| FBXY-YZ 280/1500 | 71 | 5.3 | 8040×2050×1760 | 1500×1500×65 | 34300 | ||

| FBXY-YZ 300/1500 | 75 | 5.7 | 8300×2050×1760 | 1500×1500×65 | 35900 | ||

| FBXZ-YZ 320/1500 | 81 | 6 | 8690×2050×1760 | 1500×1500×65 | 37640 | ||

| FBXZ-YZ 340/1500 | 87 | 6.4 | 9080×2050×1760 | 1500×1500×65 | 39560 | ||

| FBXZ-YZ 400/1500 | 101 | 7.6 | 9990×2050×1760 | 1500×1500×65 | 44230 | ||

| FBXZ-YZ 450/1500 | 115 | 8.5 | 10900×2050×1760 | 1500×1500×65 | 48520 | ||

| FBXZ-YZ 500/1500 | 127 | 9.5 | 11680×2050×1760 | 1500×1500×65 | 51360 | ||

| FBXZ-YZ 560/1500 | 143 | 10.6 | 12720×2050×1760 | 1500×1500×65 | 57480 | ||

| FBXY-YZ 400/1800 | 69 | 7.6 | 8085×2300×2100 | 1800×1800×65 | ≤0.8 | 8 | 47600 |

| FBXY-YZ 450/1800 | 77 | 8.5 | 8605×2300×2100 | 1800×1800×65 | 51900 | ||

| FBXY-YZ 500/1800 | 87 | 9.5 | 9255×2300×2100 | 1800×1800×65 | 57000 | ||

| FBXY-YZ 560/1800 | 97 | 10.6 | 9905×2300×2100 | 1800×1800×65 | 63200 | ||

| FBXY-YZ 600/1800 | 103 | 11.4 | 10295×2300×2100 | 1800×1800×65 | 64790 | ||

| FBXZ-YZ 630/1800 | 109 | 11.9 | 10685×2300×2100 | 1800×1800×65 | 67400 | ||

| FBXZ-YZ 700/1800 | 121 | 13.3 | 11465×2300×2100 | 1800×1800×65 | 73800 | ||

| FBXZ-YZ 750/1800 | 129 | 14 | 11855×2300×2100 | 1800×1800×65 | 77500 | ||

| FBXZ-YZ 800/1800 | 139 | 15.2 | 12635×2300×2100 | 1800×1800×65 | 82500 | ||

| FBXZ-YZ 900/1800 | 157 | 17 | 13805×2300×2100 | 1800×1800×65 | 93700 | ||

| FBXZ-YZ 1000/1800 | 175 | 19 | 14975×2300×2100 | 1800×1800×65 | 96000 | ||

| FBXZ-YZ 1100/1800 | 191 | 20.9 | 16015×2300×2100 | 1800×1800×65 | 105800 | ||

| FBXZ-YZ 1200/1800 | 209 | 22.8 | 17185×2300×2100 | 1800×1800×65 | 118600 |

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

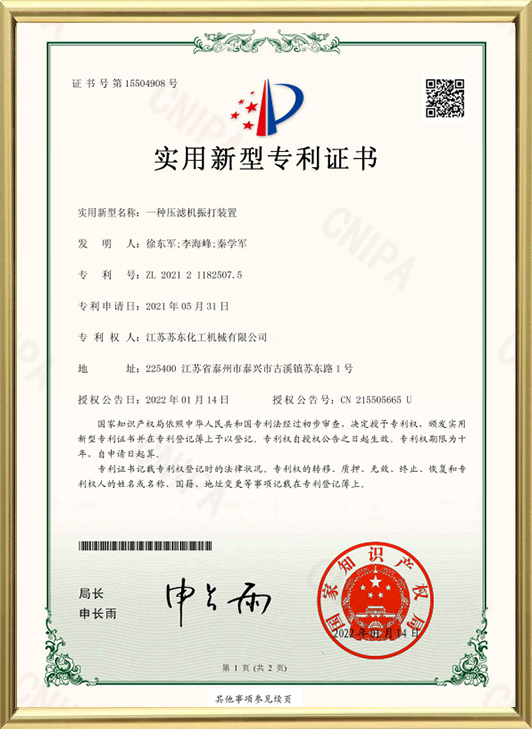

1. What is a composite rubber plate diaphragm filter press?

The composite rubber plate diaphragm filter press is an advanced solid-liquid separation equipment specially designed for efficient separation of solid matter in liquids. Its core component is a composite rubber diaphragm filter plate, which is made of high-quality chloroprene rubber from famous suppliers such as DuPont in the United States and Chongqing Changshou. After mixing and modification, the rubber and the steel skeleton are composite vulcanized under high pressure to form a diaphragm filter plate with excellent performance. The sealing surface of the filter plate maintains elastic contact with other components to ensure good sealing performance. Compared with traditional filter plates, the design of the composite rubber diaphragm filter plate can better adapt to various complex working environments and provide more efficient filtering effects.In the solid-liquid separation process, the sealing of the filtration system is crucial, especially when it is necessary to handle liquids containing fine solid particles. With its excellent sealing performance, the composite rubber plate diaphragm filter press can effectively avoid leakage problems, thereby ensuring the safety and reliability of the filtration process. In addition, the modular design of the composite rubber plate diaphragm filter press makes it easy to maintain and operate, greatly improving its service life and work efficiency.

The composite rubber plate diaphragm filter press produced by Jiangsu Sudong Chemical Machinery Co., Ltd. is widely used for solid-liquid separation in petrochemical, nonferrous metallurgy, fine chemical and other industries. These industries usually require efficient separation equipment to handle large amounts of solid waste, and the composite rubber plate diaphragm filter press has become the preferred equipment for these industries with its excellent filtering effect and economy.

2. What are the key advantages of composite rubber diaphragm plates?

The application of composite rubber diaphragm plates brings many significant advantages, one of the most notable features of which is the low moisture content of the filter cake. Through the squeezing action of the diaphragm, the moisture in the filter cake can be greatly reduced, thereby improving the efficiency of the filtration process. The diaphragm filter press of Jiangsu Sudong Chemical Machinery Co., Ltd. can achieve a squeezing pressure of 1.6 MPa through the diaphragm pressure, which not only ensures the efficiency of solid-liquid separation, but also increases the processing volume. In addition, due to the reusability of the steel skeleton, the economic benefits of the entire system are greatly improved.

Another key advantage of the composite rubber diaphragm plate is its versatility. The equipment can be equipped with various automated functions, such as automatic plate pulling, automatic liquid connection, automatic slag unloading and automatic filter cloth cleaning. These automated options combined with the PLC automatic control system make the operation process safer, simpler and more automated. Operators can easily control the operation of the equipment through a simple and clear control panel, which effectively reduces operating errors and manual intervention.

For industries that need to handle large amounts of solid waste, the high efficiency and low cost of composite rubber diaphragm plates make them an ideal choice. Since the steel skeleton in the filter plate can be recycled and reused many times, the operating cost is greatly reduced. Jiangsu Sudong Chemical Machinery Co., Ltd.'s products excel in these aspects and have been highly praised by users. Whether in the chemical, metallurgical or other industries, composite rubber diaphragm plates can provide enterprises with efficient and economical solid-liquid separation solutions.

3. How to ensure the structural integrity and service life of the filter press?

The structural design of the Composite Rubber Plate Diaphragm Filter Press fully considers the strength and durability of the equipment. The filter press frame produced by Jiangsu Sudong Chemical Machinery Co., Ltd. is welded with high-strength steel to ensure the high strength and stability of the frame. This design can not only cope with the huge pressure under high-pressure operating conditions, but also maintain the structural integrity of the equipment for a long time, thereby extending its service life.

In the solid-liquid separation process, the filter press often needs to withstand extremely high working pressure, especially when dealing with high-viscosity or high-concentration materials. To this end, the composite rubber plate diaphragm filter press of Jiangsu Sudong Chemical Machinery Co., Ltd. adopts a carefully designed and manufactured high-strength frame to ensure that the equipment can maintain stable performance under various working environments. This powerful structural design not only improves the durability of the equipment, but also reduces maintenance costs, allowing users to use the equipment for a long time and efficiently.

The frame structure of the composite rubber plate diaphragm filter press has been optimized many times to ensure its reliability under various extreme conditions. The selection of frame materials and the control of manufacturing processes are strictly implemented in accordance with industry standards to ensure that each device can meet the highest quality standards. Jiangsu Sudong Chemical Machinery Co., Ltd. has successfully extended the service life of the equipment through strict quality control and innovative design, making it extremely competitive in the market.

In practical applications, the composite rubber plate diaphragm filter press is widely used in solid-liquid separation processes in many industries due to its strong structure and long service life. These industries include petrochemical, nonferrous metallurgy, fine chemicals, etc., which have very high requirements for equipment, especially in the case of long-term continuous operation. Jiangsu Sudong Chemical Machinery Co., Ltd.'s composite rubber plate diaphragm filter press provides users with reliable solid-liquid separation solutions with its excellent structural design and long service life, helping enterprises improve production efficiency and reduce operating costs.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt