As China Automatic Efficient Water Washing Filter Press Manufacturers and Automatic Efficient Water Washing Filter Press Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

Automatic Efficient Water Washing Filter Press

Application range: The product is widely used in solid-liquid separation with high viscosity and difficult-to-handle filter media.

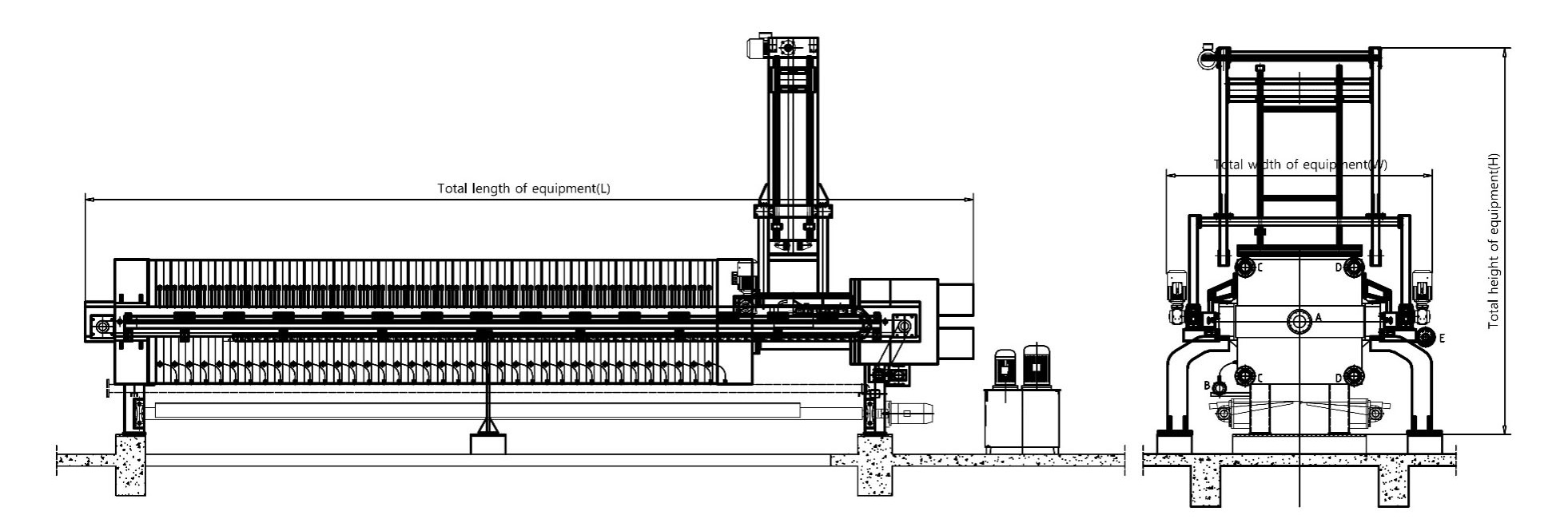

Product features: The machine is equipped with an automatic control system, which can achieve timed and quantitative flushing according to the working conditions, saving manual operation.

Product advantages: 1. After the filter press is unloaded, the equipment automatically starts the water flushing system, and the filter cloth is regularly brushed by the nozzle and brush to prevent the filter cloth from being blocked.

2. Use high-pressure water to clean the filter cloth, which can more effectively remove the blockages and impurities on the filter cloth, thereby improving the filtration efficiency and extending the service life of the filter cloth.

3. Through reasonable design and control, it can save water and reduce operating costs.

Product details

| Specification | Number Of Filter Plates | Filter Chamber Volume(m3) | Overall Dimensions(mm) | Filtration Pressure | Pressing Pressure | Matching Power (KW) | Weight Of Single Machine(Kg) |

| XAMYZG20/800-U | 9 | 0.3 | 3755×1900×3300 | ≤0.8 | ≤1.2 | 5.65 | 3100 |

| XAMYZG30/800-U | 14 | 0.45 | 5385×1900×3300 | 3400 | |||

| XAMYZG40/800-U | 19 | 0.6 | 5005×1900×3300 | 3800 | |||

| XAMYZG45/800-U | 21 | 0.675 | 5285×1900×3300 | 4000 | |||

| XAMYZG50/800-U | 24 | 0.75 | 5635×1900×3300 | 4200 | |||

| XAMYZG60/800-U | 29 | 0.9 | 6265×1900×3300 | 4600 | |||

| XAMYZG80/800-U | 39 | 1.2 | 7745×1900×3300 | 5450 | |||

| XAMYZG40/1000-U | 24 | 0.6 | 3885×2200×3600 | 4600 | |||

| XAMYZG50/1000-U | 30 | 0.75 | 5235×2200×3600 | 4900 | |||

| XAMYZG60/1000-U | 36 | 0.9 | 5665×2200×3600 | 5250 | |||

| XAMYZG70/1000-U | 42 | 1.05 | 6065×2200×3600 | 5550 | |||

| XAMYZG80/1000-U | 48 | 1.2 | 6530×2200×3600 | 5900 | |||

| XAMYZG90/1000-U | 54 | 1.35 | 6945×2200×3600 | 6300 | |||

| XAMYZG100/1000-U | 60 | 1.5 | 7365×2200×3600 | 6700 | |||

| XAMYZG110/1000-U | 66 | 1.65 | 7795×2200×3600 | 7050 | |||

| XAMYZG120/1000-U | 72 | 1.8 | 8065×2200×3600 | 7250 | |||

| XAMYZG100/1250-U | 38 | 1.5 | 6200×2600×4100 | ≤0.8 | ≤1.2 | 10.25 | 8200 |

| XAMYZG120/1250-U | 46 | 1.8 | 6800×2600×4100 | 8700 | |||

| XAMYZG140/1250-U | 52 | 2.1 | 7250×2600×4100 | 9100 | |||

| XAMYZG150/1250-U | 56 | 2.25 | 7550×2600×4100 | 9500 | |||

| XAMYZG160/1250-U | 60 | 2.4 | 7850×2600×4100 | 10000 | |||

| XAMYZG180/1250-U | 68 | 2.7 | 8450×2600×4100 | 10700 | |||

| XAMYZG200/1250-U | 76 | 3 | 9050×2600×4100 | 11600 | |||

| XAMYZG220/1250-U | 82 | 3.3 | 9500×2600×4100 | 12000 | |||

| XAMYZG250/1250-U | 94 | 3.75 | 10400×2600×4100 | 13500 | |||

| XAMYZG200/1500-U | 52 | 3 | 8165×3100×5100 | ≤0.8 | ≤1.2 | 10.75 | 21100 |

| XAMYZG250/1500-U | 64 | 3.75 | 9155×3100×5100 | 23200 | |||

| XAMYZG300/1500-U | 76 | 4.5 | 10145×3100×5100 | 25300 | |||

| XAMYZG350/1500-U | 90 | 5.3 | 11805×3100×5100 | 27800 | |||

| XAMYZG400/1500-U | 102 | 6 | 12795×3100×5100 | 29500 | |||

| XAMYZG450/1500-U | 116 | 6.75 | 13955×3100×5100 | 31200 | |||

| XAMYZG500/1500-U | 128 | 7.5 | 14945×3100×5100 | 33200 | |||

| XAMYZG 600/2000-U | 84 | 10.5 | 11980×3600×6200 | ≤0.8 | ≤1.2 | 17.15 | 48000 |

| XAMYZG 700/2000-U | 100 | 12.25 | 13360×3600×6200 | 52000 | |||

| XAMYZG800/2000-U | 116 | 14 | 14660×3600×6200 | 56000 | |||

| XAMYZG900/2000-U | 132 | 15.75 | 16045×3600×6200 | 60000 | |||

| XAMYZG1000/2000-U | 144 | 17.5 | 17085×3600×6200 | 63000 |

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

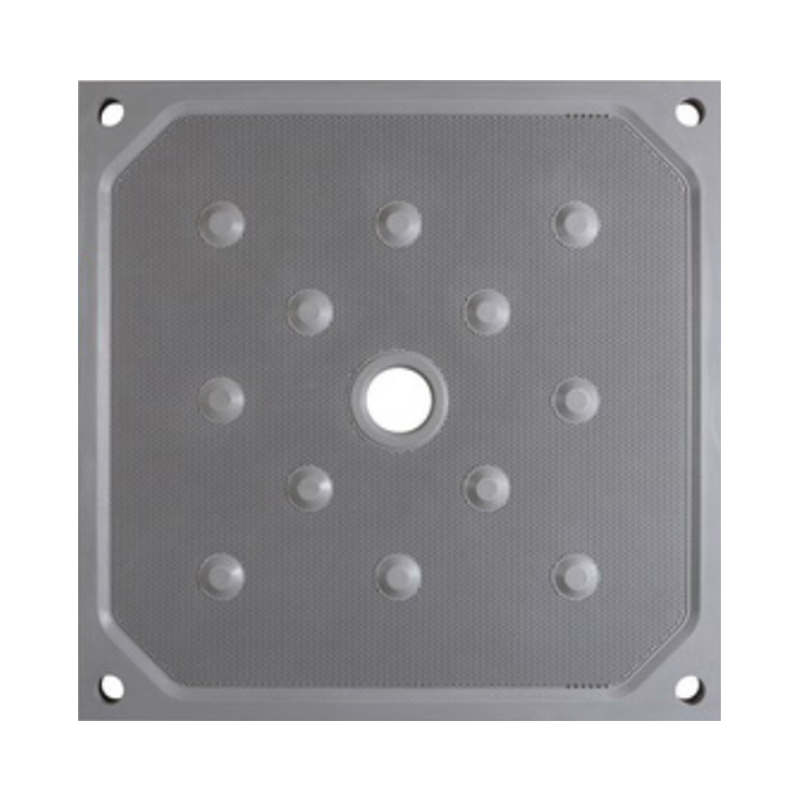

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

1.What Makes the Automatic Efficient Water Washing Filter Press Stand Out?

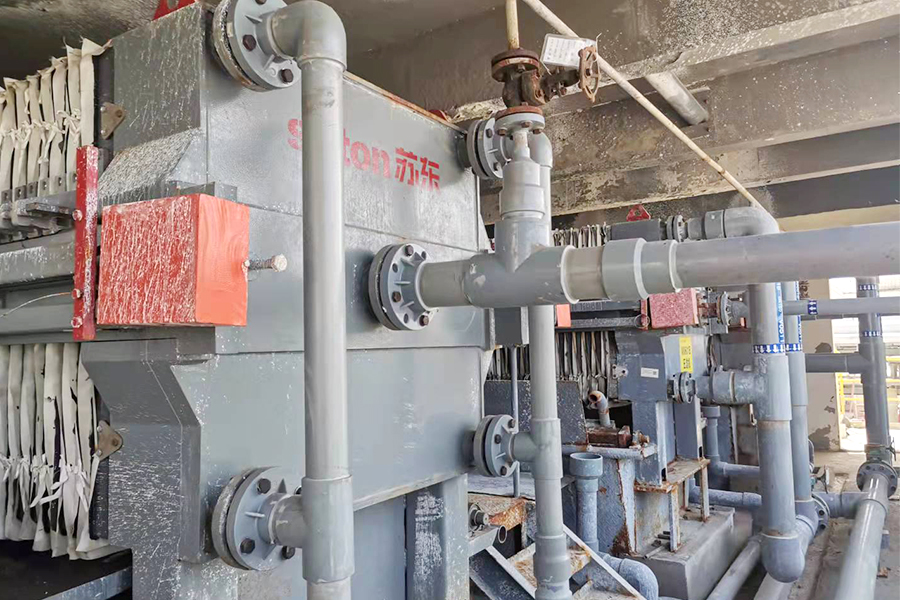

The Automatic Efficient Water Washing Filter Press is not just another piece of industrial equipment; it is a revolutionary solution that redefines efficiency and reliability in the filtration industry. Developed by Jiangsu Sudong Chemical Machinery Co., Ltd., a company with over three decades of experience in filter press design and manufacturing, this machine embodies the pinnacle of modern filtration technology. What sets this filter press apart is its integration of automation and precision engineering, designed to meet the rigorous demands of industries such as chemical manufacturing, mining, and wastewater treatment.

One of the key features that makes the Automatic Efficient Water Washing Filter Press stand out is its fully automated operation. Traditional filter presses often require significant manual intervention to manage the filtration cycles, clean the filter cloths, and discharge the filtered solids. However, this advanced model automates these processes, significantly reducing the need for manual labor. The automation system is equipped with intelligent controls that monitor the filtration process in real time, adjusting parameters as needed to ensure optimal performance. This level of automation not only enhances operational efficiency but also ensures consistent and repeatable results, which is crucial in industries where precision is paramount.

The design of the Automatic Efficient Water Washing Filter Press incorporates robust materials and advanced engineering principles to ensure durability and reliability. The frame and other structural components are typically made from high-strength steel, capable of withstanding the high pressures required for effective filtration. The filter plates, which are the heart of the filtration process, are designed to maximize surface area while minimizing resistance to flow, ensuring that the machine can handle large volumes of slurry with ease.

2.How Does the Water Washing System Enhance Filtration Performance?

The water washing system integrated into the Automatic Efficient Water Washing Filter Press is a critical component that significantly enhances the overall performance of the filtration process. In traditional filter presses, one of the common challenges is the clogging of filter cloths, which can lead to reduced filtration efficiency, increased cycle times, and higher maintenance costs. The water washing system addresses this challenge by ensuring that the filter cloth remains clean and unclogged, thereby maintaining optimal filtration performance throughout the operation.

The water washing system operates by automatically spraying high-pressure water onto the filter cloths after each filtration cycle. This process effectively removes any residual solids that may have adhered to the cloth during the filtration process. By keeping the filter cloth clean, the system prevents the buildup of materials that could impede the flow of liquid through the filter, which in turn maintains the speed and efficiency of the filtration process. This is particularly important in industries where fine particles or sticky substances are filtered, as these materials are more likely to cause clogging.

The water washing system contributes to extending the lifespan of the filter cloths. In traditional filter presses, filter cloths may need to be replaced frequently due to the buildup of residues that are difficult to remove manually. The automatic washing system mitigates this issue by providing a thorough and consistent cleaning after each cycle, reducing wear and tear on the cloths. This not only lowers the operational costs associated with frequent cloth replacements but also reduces downtime, as the filter press can operate for longer periods without the need for maintenance.

Another significant advantage of the water washing system is its contribution to maintaining the quality of the filtered product. In processes where the purity of the filtered liquid or the dryness of the filtered solids is crucial, any residue left on the filter cloth can compromise the quality of the end product. By ensuring that the filter cloth is always clean, the water washing system helps to produce a higher quality filtrate and drier filter cake, which can be a critical factor in industries such as pharmaceuticals, food processing, and chemical manufacturing.

3.Why Is the Automatic Efficient Water Washing Filter Press an Environmentally Friendly Choice?

In today’s industrial landscape, where environmental protection is a key priority, the Automatic Efficient Water Washing Filter Press stands out as a leading example of sustainable technology. Jiangsu Sudong Chemical Machinery Co., Ltd., with its long history and commitment to environmental protection, has designed this filter press to not only enhance operational efficiency but also to minimize its impact on the environment. This makes the Automatic Efficient Water Washing Filter Press an ideal choice for companies looking to align their operations with environmental sustainability goals.

One of the primary reasons this filter press is considered environmentally friendly is its ability to reduce waste. During the filtration process, the machine effectively separates solids from liquids, producing a dry filter cake that can be easily handled, stored, or disposed of. By maximizing the dryness of the filter cake, the press minimizes the volume of waste, reducing the burden on waste disposal systems and lowering the environmental impact of waste management. In some cases, the dry filter cake can even be repurposed or recycled, further contributing to sustainable practices.

Another environmental advantage of the Automatic Efficient Water Washing Filter Press is its efficient use of water. The water washing system, which is integral to maintaining the performance of the filter press, is designed to be highly efficient, using only the necessary amount of water for cleaning the filter cloths. More importantly, the system is equipped to recycle the water used during the washing process. This closed-loop system ensures that water consumption is kept to a minimum, reducing the strain on local water resources and aligning with best practices for water conservation.

The filter press also supports the reduction of energy consumption, which is a crucial factor in minimizing the environmental footprint of industrial operations. The automation features of the press ensure that the machine operates at optimal efficiency, with minimal energy waste. By automating the filtration cycle and the washing process, the press reduces the need for manual intervention and ensures that the machine operates only when necessary, further lowering energy consumption. This not only helps to reduce operational costs but also supports the broader goal of reducing greenhouse gas emissions associated with industrial energy use.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt