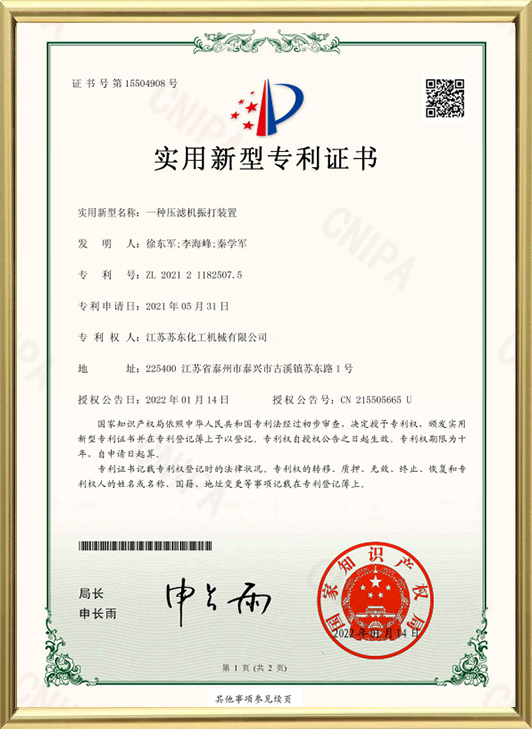

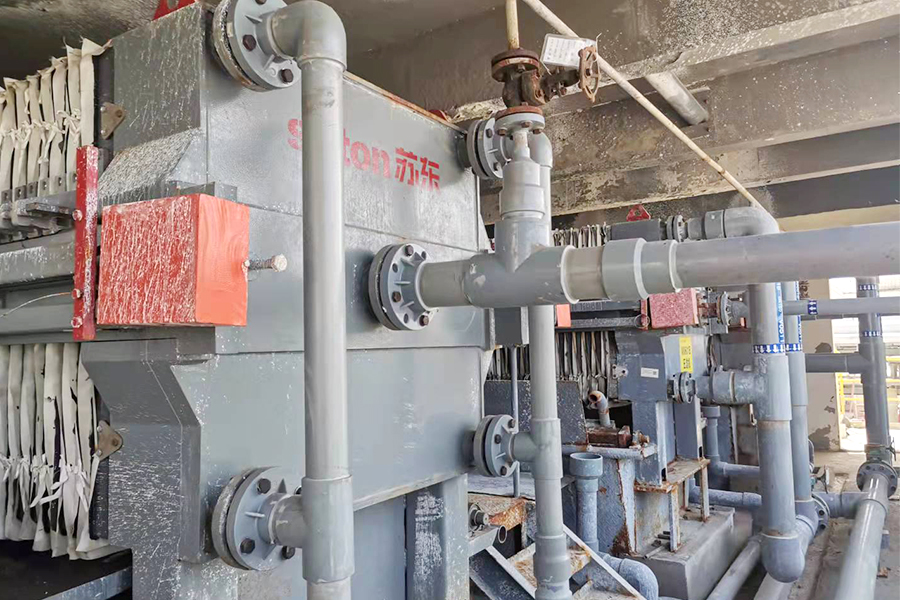

As China Pharmaceutical preparation device Manufacturers and Pharmaceutical preparation device Suppliers, Jiangsu Sudong Chemical Machinery Co., Ltd. was founded in June 1956. It is an environmental protection technology-based enterprise integrating filter press technology research and development, a complete set of filtration equipment manufacturing, and environmental protection engineering contracting. It has been engaged in the design and manufacturing of filter presses for more than 30 years. It is a well-known professional enterprise in domestic multi-variety filter press manufacturing. It has been recognized as a high-tech enterprise in Jiangsu Province and one of the top ten competitive enterprises in China's chemical machinery industry. In 2013, it was approved by the Jiangsu Provincial Department of Education and the Jiangsu Provincial Department of Science and Technology as a Jiangsu Provincial Enterprise Graduate Workstation and established the Taizhou Solid-Liquid Separation Equipment Engineering Technology Research Center.

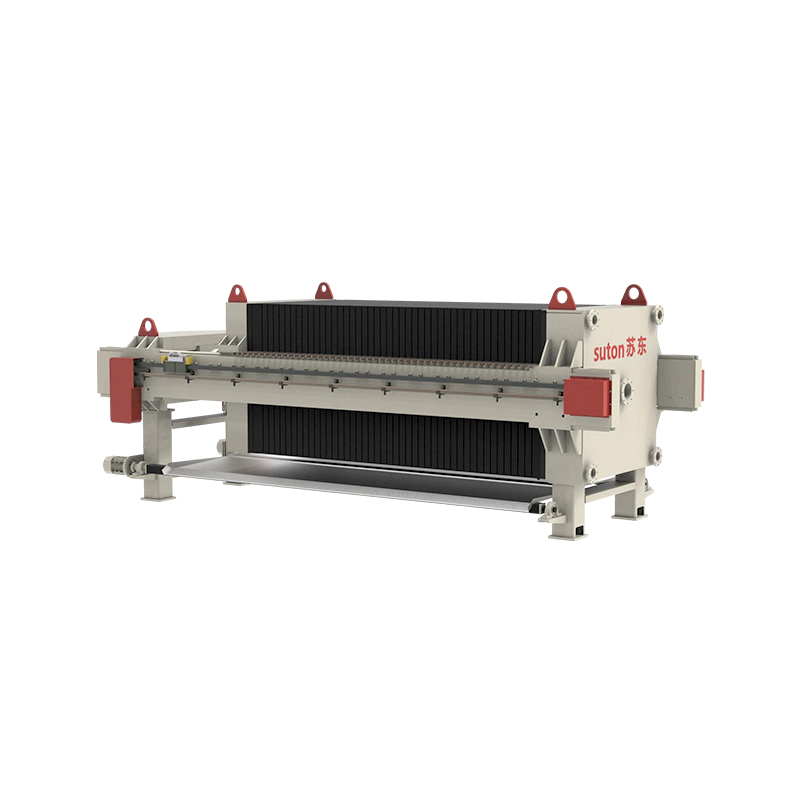

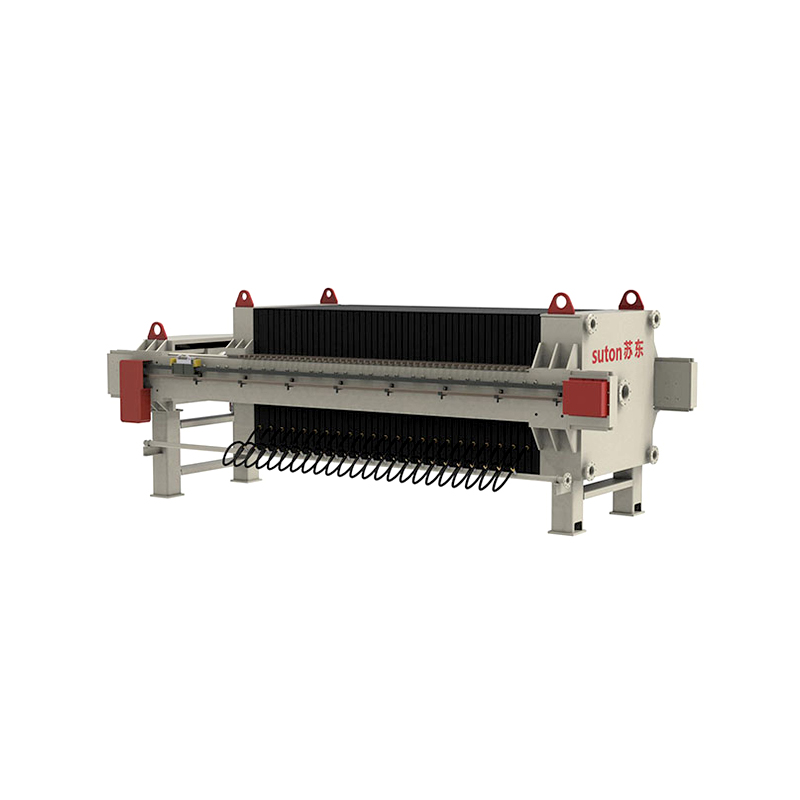

Pharmaceutical preparation device

Application range: The product is widely used in water treatment, sewage treatment, chemical industry and other fields. For example, it is used to add flocculants, disinfectants, etc. in sewage treatment to achieve the purpose of purifying water quality. Through the rational use of the dosing device, the treatment effect and efficiency can be effectively improved, and the stable operation of the process can be guaranteed.

Product features: The dosing device is a device used for accurate dosing of chemical agents. It usually includes a storage tank, a metering pump, an agitator, a control system and other parts. Its main function is to accurately add the agent to the treatment system according to the set ratio and dosage.

Product advantages: 1. Accurate metering: can ensure the accuracy of the agent dosage.

2. High degree of automation: can realize automatic control and adjustment, and reduce manual operation.

3. Strong adaptability: can handle a variety of different types of agents and application scenarios.

4. Convenient operation: easy to monitor and manage.

Product details

Application

-

Sewage Treatment Plant XMYZGF80-800-U

Sewage Treatment Plant XMYZGF80-800-U

-

River Water Purification XMYZGFS100-1000-U2 Units

River Water Purification XMYZGFS100-1000-U2 Units

-

Chlor-alkali FBXYZ300-1500

Chlor-alkali FBXYZ300-1500

-

Salt Mud FBXYZ200-1250

Salt Mud FBXYZ200-1250

-

Salt Mud Treatment FBXYZ1800-500

Salt Mud Treatment FBXYZ1800-500

-

XAYZGF700-2000-UK

XAYZGF700-2000-UK

-

Carbide Slag Treatment

Carbide Slag Treatment

-

Chlor-alkali Chemical Industry, Salt Mud

Chlor-alkali Chemical Industry, Salt Mud

-

800 Square Diaphragm

800 Square Diaphragm

-

Nonferrous Metallurgy XMYZG220-1250-U

Nonferrous Metallurgy XMYZG220-1250-U

-

Xinjiang Case

Xinjiang Case

-

Anhui Bean Odule XAYZG200-1250

Anhui Bean Odule XAYZG200-1250

Keep In Touch

-

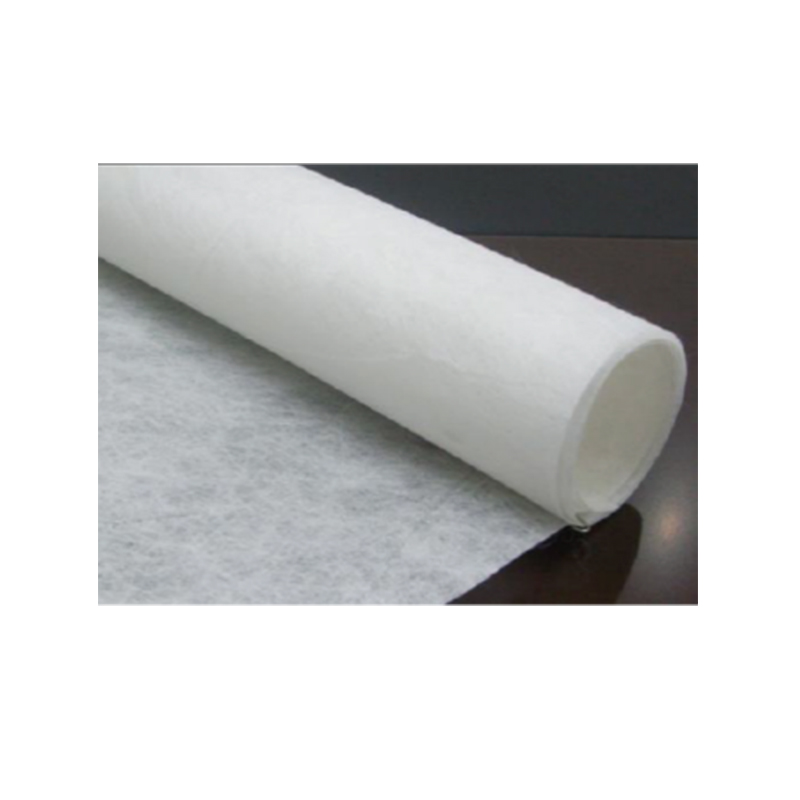

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation? Definition:A Fil...

READ MORE -

1. Why Filtration Efficiency Matters in Chemical Processing In the chemical industry, precision and ...

READ MORE -

Introduction: The Need for Efficient Solid-Liquid Separation In many industrial processes—such as mi...

READ MORE -

Introduction Filtration is a critical process in many industrial sectors, from wastewater treatment ...

READ MORE -

Particle Size Impact: Particle size directly determines the selection of filter cloth and filter ...

READ MORE

Core technical advantages of pharmaceutical preparation device

In the pharmaceutical industry, the formulation and dosage requirements of drugs are extremely strict. In pharmaceutical production, any measurement error of drugs may directly affect the quality of drugs and even lead to unqualified product batches. Jiangsu Sudong Chemical Machinery Co., Ltd., relying on years of mechanical industry technology, adopts a high-precision metering system for pharmaceutical preparation device to ensure the accuracy of drug dosing. This feature is particularly critical in the production of drugs such as antibiotics and vaccines that require strict dosage control.

Another significant advantage of accurate drug metering is that it can significantly reduce drug waste. In the pharmaceutical industry, the cost of many raw materials and active ingredients is extremely high. If the drug is not accurately added, the cost of drug production may increase significantly. The dosing device ensures that the amount of drug used is always within the optimal range through precise metering control to avoid unnecessary waste. This not only helps pharmaceutical companies save raw material costs, but also improves the economic benefits of the production line and makes the production process more sustainable.

The pharmaceutical industry is subject to strict global supervision, and product quality control and compliance are the key to the survival and development of enterprises. The dosing device strictly follows GMP and other relevant standards during the design and manufacturing process to ensure that each device meets the strict requirements of drug production. The precise metering function avoids production deviations caused by inaccurate addition of agents, ensures the compliance of drug production, and helps customers pass various reviews and certifications smoothly.

The pharmaceutical industry involves the use of a variety of agents and formulations, which have different physical and chemical properties, such as viscosity, solubility, and reactivity. Therefore, the dosing device needs to have the ability to handle multiple types of agents. The dosing device is flexible in design and can easily cope with the processing needs of different types of agents. Whether it is a water-soluble agent that needs to be accurately dosed or a solution with special chemical properties, it can be accurately and stably dosed through the device, ensuring the stability and continuity of the production process.

In the pharmaceutical production process, process conditions such as temperature, pressure, and pH often change, which poses a challenge to the stability and adaptability of the dosing device. The dosing device has excellent environmental adaptability and can maintain stable operation under various harsh process conditions. Through the use of corrosion-resistant materials and precise control system design, the device can not only cope with complex process environments, but also maintain accurate dosing of agents for a long time to ensure the continuity of the production process.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt