How Can You Improve Filtration Efficiency with the Right Filter Press Plate Design?

2025.10.20

2025.10.20

Industry News

Industry News

1. Why Filtration Efficiency Matters in Chemical Processing

In the chemical industry, precision and consistency are critical. Whether separating solids from liquids in pigments, dyes, or catalysts, efficient filtration directly affects production output and product purity. A well-designed filter press plate can significantly reduce filtration cycle times, minimize energy consumption, and ensure higher-quality filtrate.

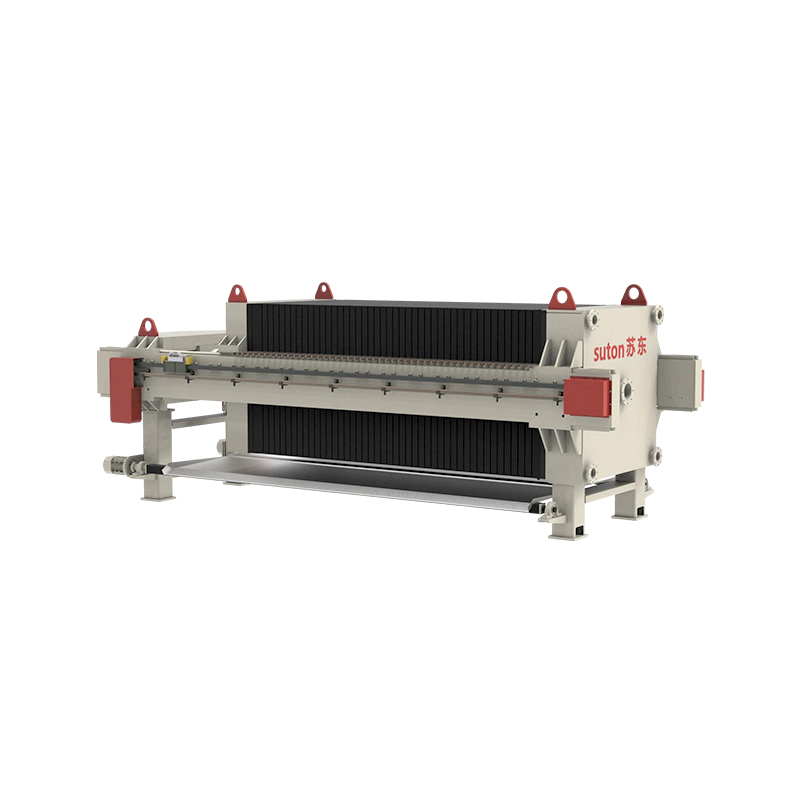

2. Understanding Filter Press Plate Design Basics

Filter press plates are the heart of the filtration process. They define how slurry flows, how pressure is distributed, and how effectively solids are separated from liquids. The most common plate types include:

Chamber Plates (Recessed Plates):

The most widely used in chemical processing. They offer good cake formation and easy maintenance.

Membrane Plates:

Feature flexible membranes that can be inflated to “squeeze” the filter cake, reducing residual moisture and improving dryness.

Plate and Frame Plates:

Ideal for fine filtration and applications requiring thorough washing, though less common in modern automated systems.

Each plate type comes in different materials (polypropylene, PVDF, stainless steel, or cast iron), and each has distinct advantages based on the chemical compatibility and operating temperature.

3. Key Design Factors That Affect Filtration Efficiency

To improve filtration performance, it’s essential to understand how design parameters influence efficiency.

a. Plate Material

For chemical applications, polypropylene plates are the industry standard due to their excellent chemical resistance and lightweight structure. In high-temperature or highly corrosive environments, PVDF or stainless steel plates may be more suitable.

Tip: Matching the plate material to your chemical properties reduces corrosion risk and extends plate life.

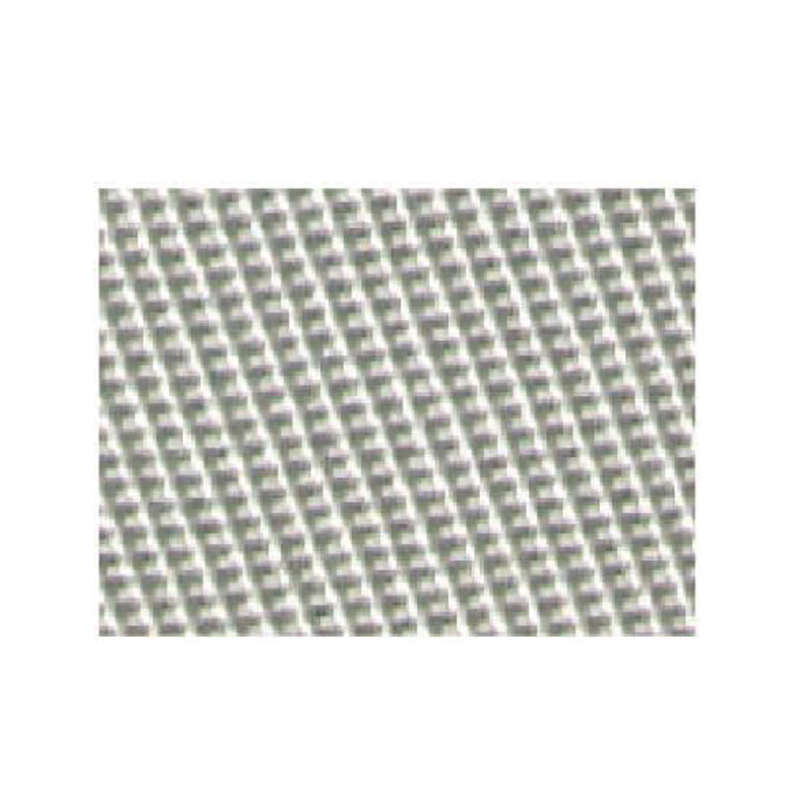

b. Filtration Surface Pattern

The raised patterns or grooves on the plate surface help distribute slurry evenly and support the filter cloth. A well-designed surface pattern allows faster filtrate flow and prevents clogging.

Plates with optimized drainage channels and uniform surface textures reduce resistance and enhance cake release, saving valuable cycle time.

c. Feed Channel and Drainage Design

Flow distribution is crucial for consistent filtration. Poor channel design can lead to uneven cake thickness or partial clogging.

Modern plates often feature center feed or corner feed systems, depending on the slurry viscosity and flow behavior. Selecting the right feed configuration improves throughput and ensures balanced pressure across all chambers.

d. Membrane Compression Technology

Membrane plates use compressed air or water to apply secondary pressure to the cake after the initial filtration phase.

This design achieves:

- Lower residual moisture (up to 20–30% drier cakes)

- Shorter drying times

- Better washing efficiency

For chemical plants dealing with fine particles or high-moisture slurries, membrane plates can dramatically enhance productivity and product recovery.

4. Matching Plate Design to Your Chemical Application

Choosing the right plate design depends on several process variables:

|

Application Type |

Recommended Plate Type |

Notes |

|

Acidic Slurry (e.g., phosphate, dyes) |

Polypropylene Chamber Plate |

Excellent chemical resistance |

|

High-Temperature Process |

Stainless Steel or PVDF Plate |

Withstands heat and corrosion |

|

Fine Chemical Filtration |

Membrane Plate |

Improves cake dryness and washing |

|

Viscous or Sticky Slurry |

Deep Chamber Plate |

Allows higher cake capacity |

Pro Tip: Always consider not just the material, but also the plate thickness, filtration area, and cake depth—these factors directly influence cycle time and overall efficiency.

5. Operational Tips for Maximizing Filtration Efficiency

Once the right filter press plate is selected, proper operation and maintenance are key to sustaining performance.

- Inspect Plates Regularly– Look for cracks, warping, or misalignment that may lead to leaks.

- Ensure Proper Cloth Fitment– A poor seal between the cloth and plate reduces pressure efficiency.

- Clean Thoroughly– Residue buildup on the filtration surface increases resistance and lengthens cycles.

- Monitor Feed Pressure– Excess pressure can deform plates and shorten lifespan.

- Optimize Cycle Parameters– Adjust feed rate, pressure, and washing stages according to slurry type.

Regular inspection and timely plate replacement can reduce downtime and avoid costly production losses.

6. Case Example: Efficiency Gains in a Chemical Plant

A chemical processing plant producing titanium dioxide switched from standard chamber plates to membrane filter plates with optimized feed channels. The result:

- Cycle time reduced by 22%

- Filter cake moisture reduced by 18%

- Maintenance frequency dropped by 30%

This improvement allowed the plant to process more batches per day and significantly lower energy consumption—without upgrading the entire filter press unit.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt