What are the methods for cleaning filter press cloth? Which one is the most effective?

2025.10.27

2025.10.27

Industry News

Industry News

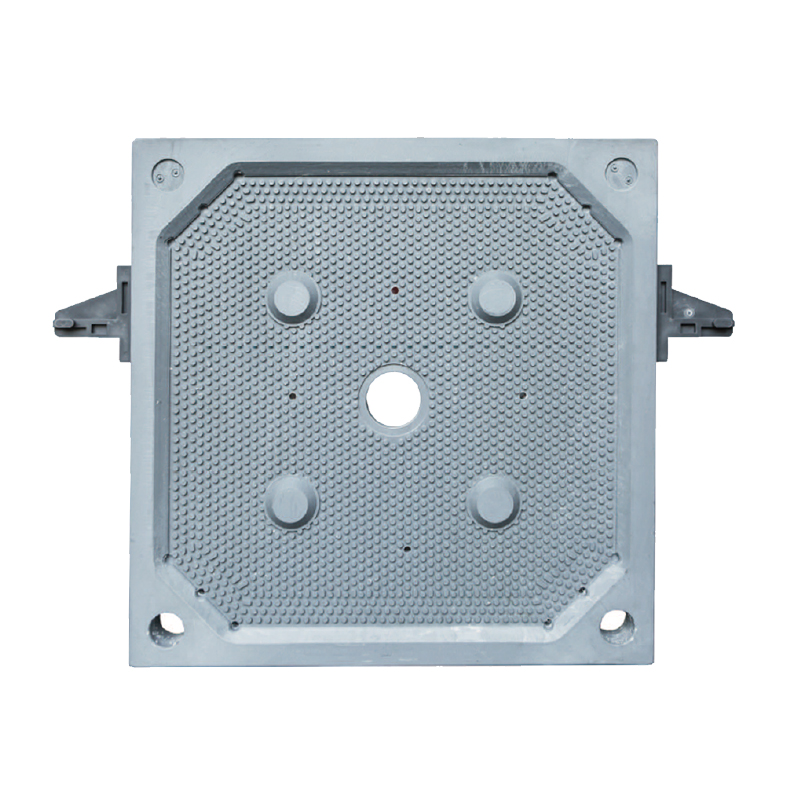

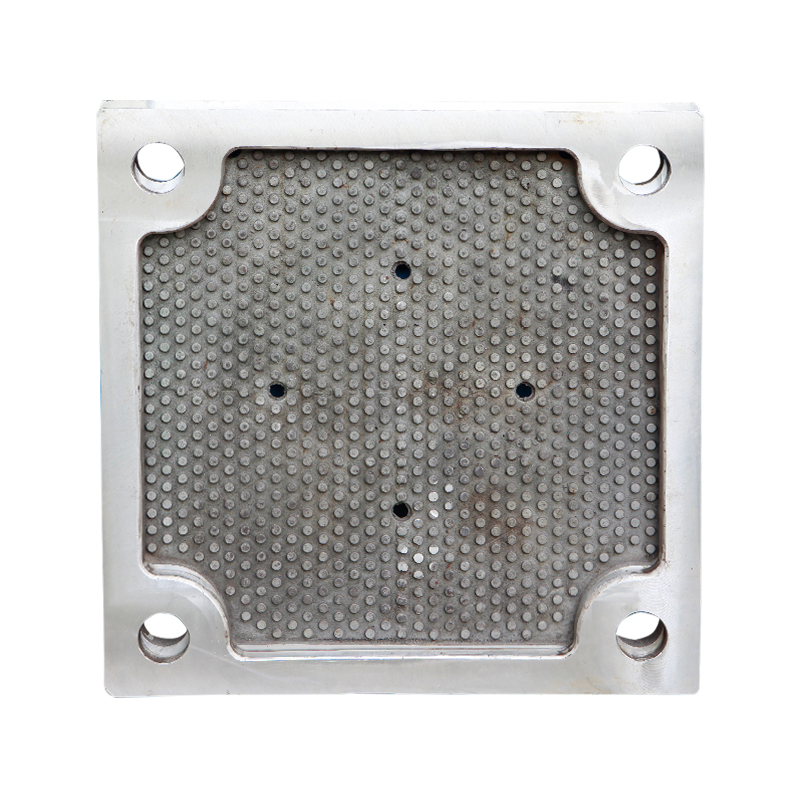

What is a Filter Press Cloth and What Role Does It Play in Solid-Liquid Separation?

Definition:

A Filter Press Cloth is an industrial filtration medium installed on filter plates of a filter press, used for solid-liquid separation. It is usually made of polyester (PET), polypropylene (PP), or polyamide (PA) fibers, offering high wear resistance and excellent filtration performance.

Functions:

- Solid-liquid separation:Captures solid particles from slurry or suspension, allowing clear filtrate to pass through.

- Filter cake formation:Supports deposition of the slurry, forming uniform filter cakes and improving dewatering efficiency.

- Filter plate protection:Prevents direct contact of solid particles with filter plates, extending equipment lifespan.

Applications: Used in wastewater treatment, mining, chemical, food processing, and pharmaceutical industries.

How to Choose the Right Filter Press Cloth for Your Equipment

Selection Criteria:

1.Material:

- PET: Wear-resistant and chemical-resistant.

- PP: Heat-resistant and corrosion-resistant.

- PA: Fine filtration with good flexibility.

2.Filtration precision: Choose mesh size based on particle size of the slurry.

3.Weave type: Plain weave, twill weave, or composite cloth affects filtrate flow and cake thickness

4.Size matching: Ensure the cloth matches the filter plate to prevent leakage.

Selection Process: Analyze slurry characteristics → Choose material and mesh precision → Consider cleaning and operational cost.

Materials of Filter Press Cloth and Which One is the Best

Common Materials and Features:

|

Material |

Features |

Applications |

|

PET |

Wear-resistant, chemical-resistant |

Wastewater treatment, mining |

|

PP |

Heat-resistant, corrosion-resistant |

Chemical wastewater, acidic/alkaline slurries |

|

PA |

Fine filtration, flexible |

Food, pharmaceuticals |

|

Coated cloth |

Anti-fouling surface |

High-viscosity sludge or oily slurries |

Selection Principles:

- High wear resistance → PET

- High chemical resistance → PP

- Fine filtration → PA

- High-viscosity or sticky sludge → Coated cloth

Why Does a Filter Press Cloth Get Clogged Easily and How to Solve It?

Causes of Clogging:

- Large or fibrous particles in the slurry.

- High-viscosity sludge or oils adhering to the cloth.

- Inadequate cleaning.

- Cloth aging or wear.

Solutions:

- Regular water or chemical cleaning.

- Select the correct mesh size and material.

- Use coated cloth or scrapers for sticky slurries.

- Replace worn-out cloths promptly.

How Often Should a Filter Press Cloth Be Replaced?

Factors Affecting Replacement Frequency: Slurry type, cloth material, usage frequency, and maintenance.

Reference Lifespan:

- Light sludge: 12–18 months

- Medium sludge: 6–12 months

- Heavy or abrasive sludge: 3–6 months

Filter Press Cloth Cleaning Methods and Which Is Most Effective

Cleaning Methods:

- High-pressure water rinse:Quick and suitable for light sludge.

- Chemical cleaning:Removes oils and mineral deposits thoroughly.

- Mechanical brushing:Effective for localized stubborn dirt.

- Ultrasonic cleaning:Thorough and uniform, ideal for fine cloths.

- Steam cleaning:Softens oils and organic deposits; environmentally friendly.

Recommended Approach:

- Daily maintenance → Water rinse.

- Periodic deep cleaning → Chemical cleaning plus water rinse.

- Fine or specialized cloths → Ultrasonic or steam cleaning.

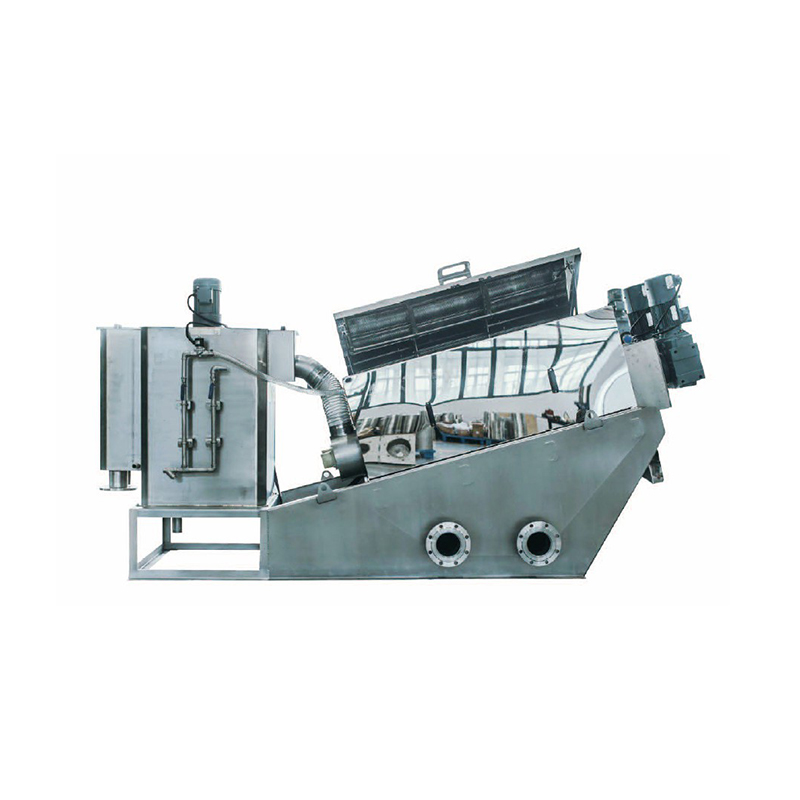

Difference Between Filter Press Cloth and Filter Belt

|

Comparison |

Filter Press Cloth |

Filter Belt |

|

Structure |

Fixed on filter plates |

Continuous loop belt |

|

Filtration Method |

Pressure filtration |

Gravity or pressure with rollers |

|

Application |

Batch solid-liquid separation |

Continuous production |

|

Filter Cake |

Uniform thickness |

Varies, continuous output |

|

Maintenance |

Cleaning and replacement |

Roller adjustment and cleaning |

How to Determine if a Filter Press Cloth Meets Filtration Precision Requirements

Evaluation Methods:

- Observing filtrate clarity.

- Measuring particle retention rate in filtrate.

- Checking dryness of the filter cake.

- Monitoring equipment pressure changes.

Regular testing ensures the cloth selection meets the process requirements.

Should You Choose Domestic or Imported Filter Press Cloth?

Comparison Factors: Price, quality, after-sales service, and suitability.

Recommendations:

- Regular industrial sludge → Domestic cloths offer better cost-performance.

- Precision or specialized filtration → Imported cloths may be preferred.

Is a Filter Press Cloth Really Important in Wastewater Treatment?

Importance:

- Serves as the core filtration medium.

- Affects production costs—clogged or worn cloths reduce efficiency.

- Ensures compliance with environmental discharge standards.

- Extends filter press lifespan.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt