Introduction to Filter Plate Series

As a preeminent

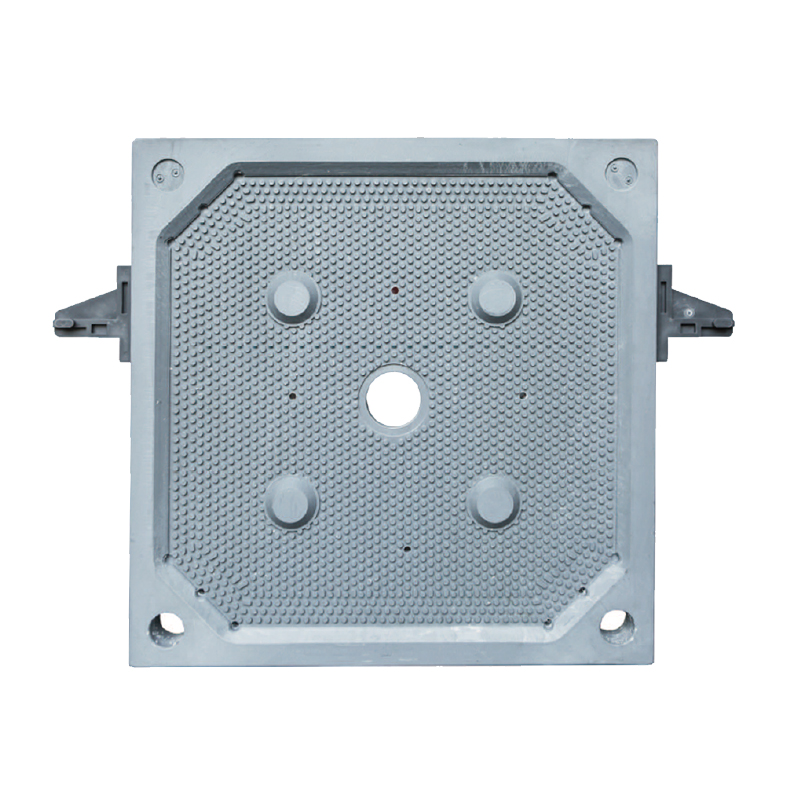

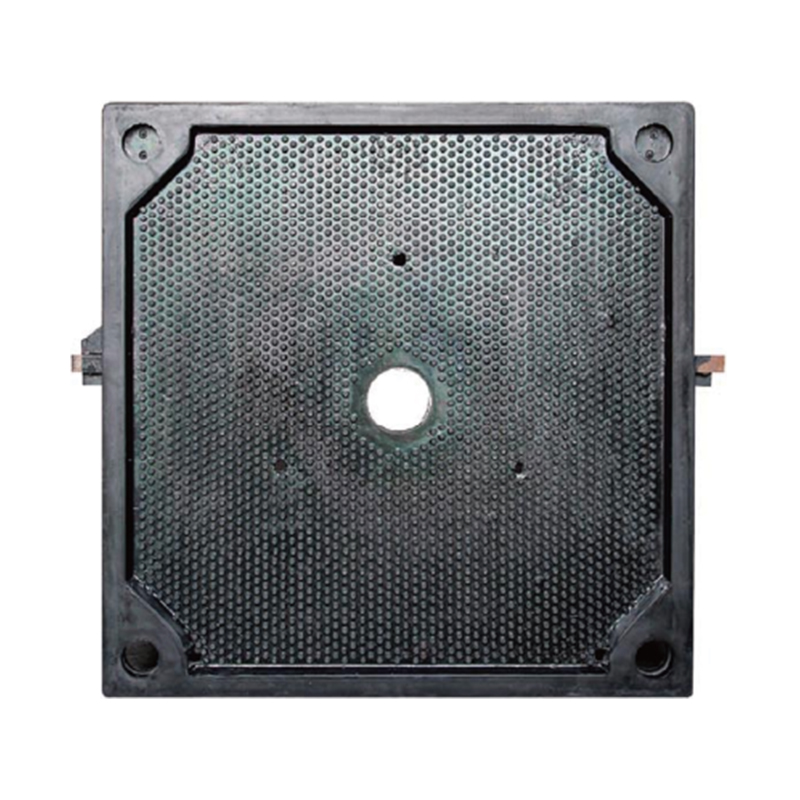

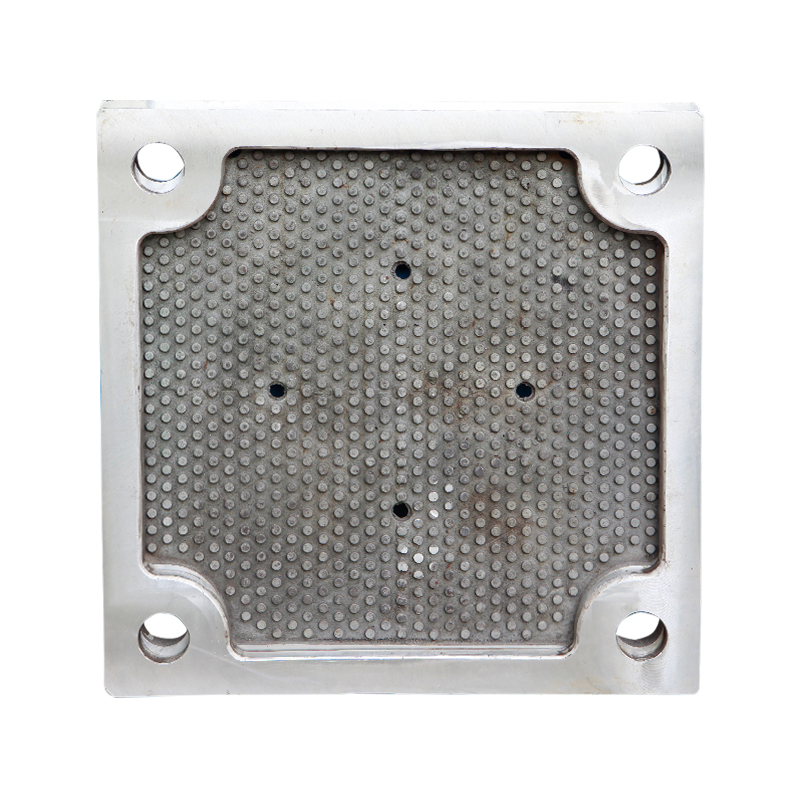

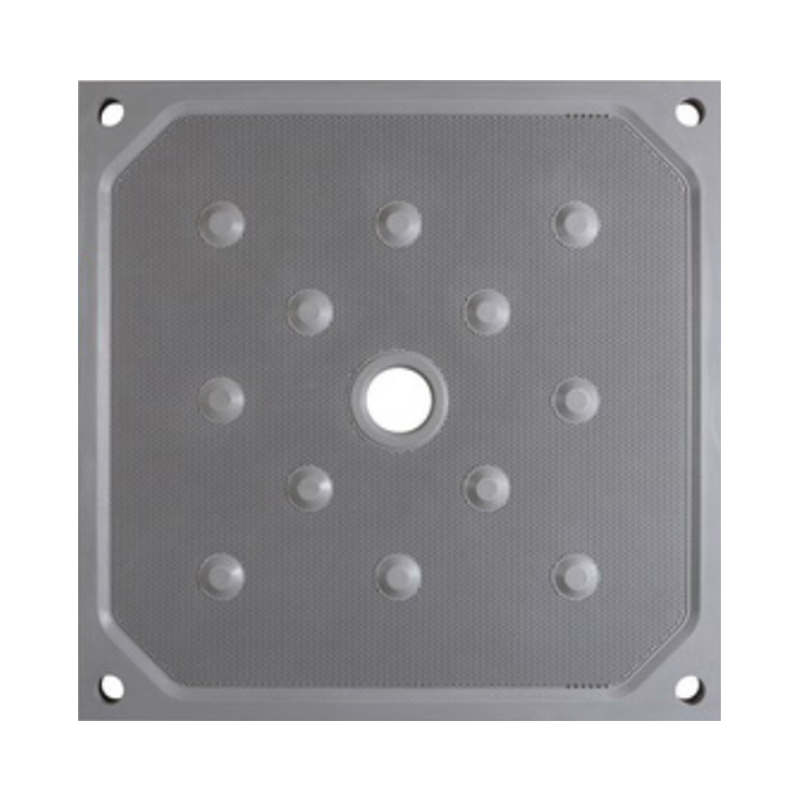

Filter Plate Series Manufacturers and Filter Plate Series Factory, Jiangsu Sudong Chemical Machinery Co., Ltd., we are committed to delivering cutting-edge filtration solutions that elevate industrial processes. Our filter plate series represents a cornerstone of our product range, meticulously engineered to optimize solid-liquid separation across diverse applications. Filter plates are the fundamental components of filter presses, industrial workhorses employed in a myriad of sectors, including chemical processing, pharmaceuticals, mining, food and beverage production, and environmental remediation. These components play a pivotal role in separating valuable solids from liquid suspensions, ensuring product purity, process efficiency, and environmental compliance. At the heart of our filter plate series lies a profound understanding of the intricate challenges faced by industries. We have invested decades in research and development to create filter plates that not only meet but exceed industry standards. Our unwavering focus on innovation has resulted in a product line that encompasses a broad spectrum of materials, designs, and dimensions, catering to the unique requirements of various filtration processes. The core function of a filter plate is to create filtration chambers within a filter press. As the slurry is pumped into the press, the liquid phase permeates through the filter medium, while the solid particles are retained on the filter plate surface, forming a filter cake. The efficiency of this separation process is directly influenced by the filter plate's material, design, and structural integrity. Our filter plates are manufactured using state-of-the-art technology and stringent quality control protocols. We employ a diverse range of materials, including stainless steel, polypropylene, and other high-performance alloys, to ensure optimal compatibility with various process fluids and operating conditions. Each filter plate undergoes rigorous testing to guarantee dimensional accuracy, pressure resistance, and corrosion resistance. Jiangsu Sudong Chemical Machinery Co., Ltd. is not merely a manufacturer of filter plates; we are a partner in your filtration journey. Our team of experts is dedicated to providing comprehensive support, from product selection to installation and after-sales service. We collaborate closely with our clients to understand their specific needs and recommend the most suitable filter plate solutions. By choosing Jiangsu Sudong Chemical Machinery Co., Ltd. as your Filter Plate Series supplier, you gain access to a wealth of expertise and a product line that embodies precision, durability, and performance. We are confident in our ability to deliver filter plates that optimize your filtration processes, enhance product quality, and contribute to your overall operational success.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt