How does the Quick Opening Filter Press ensure consistent and uniform cake formation?

2024.08.16

2024.08.16

Industry News

Industry News

Even Pressure Distribution: The Quick Opening Filter Press is meticulously designed to ensure even pressure distribution across all filter plates. The hydraulic system is engineered to deliver uniform pressure to each chamber, which is critical for achieving consistent cake formation. This system typically incorporates high-precision hydraulic pumps and regulators that control pressure with exacting accuracy. By ensuring that each chamber receives the same hydraulic force, the press prevents discrepancies in cake thickness that could arise from uneven pressure distribution. This uniform pressure application is essential for maintaining the integrity of the filter cakes and ensuring their consistent quality.

Precise Filtration Cycles: Filtration cycles in a Quick Opening Filter Press are managed through sophisticated automation and control systems. These systems use advanced programmable logic controllers (PLCs) and real-time data acquisition to precisely regulate each phase of the filtration process. The automation covers various stages including slurry feeding, pressure application, filtration, and cake discharge. By using algorithms and pre-set parameters, these systems minimize human error and process variability, leading to reliable and repeatable results. The precise control over cycle times and conditions ensures that the filter cakes are produced with uniform characteristics, such as thickness and moisture content.

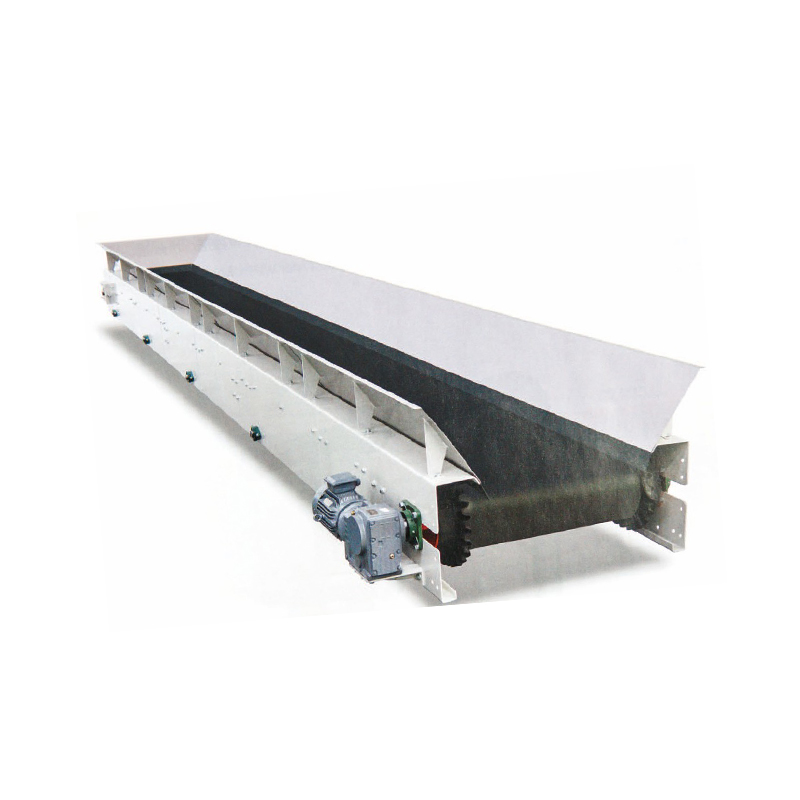

Advanced Plate Design: The filter plates in the Quick Opening Filter Press are engineered with cutting-edge design features to enhance filtration efficiency. These plates often include intricate channel configurations and surface textures designed to optimize slurry distribution. The advanced plate design ensures that the slurry is evenly dispersed across the entire filtration area, reducing the likelihood of blockages and ensuring that each chamber receives a consistent amount of feed material. The design also facilitates efficient drainage of the filtrate and aids in the formation of uniform cakes by preventing any uneven buildup of solid material.

Filtration Media Selection: Choosing the right filtration media is crucial for achieving consistent cake formation. The Quick Opening Filter Press utilizes high-performance filter cloths or membranes that are specifically selected based on their compatibility with the feed material and the desired filtration results. The filtration media is selected for its permeability, chemical resistance, and durability. High-quality media ensures even slurry flow and effective solid-liquid separation, which directly impacts the uniformity of the filter cakes. Additionally, the media is designed to maintain its structural integrity and performance over time, contributing to consistent filtration results across multiple cycles.

Controlled Feed Flow Rate: To achieve uniform cake formation, the Quick Opening Filter Press features advanced systems for controlling the feed flow rate into the filtration chambers. These systems include flow meters, regulators, and automated valves that precisely manage the rate at which slurry is introduced. By controlling the flow rate, the press prevents variations in slurry distribution that could lead to uneven cake formation. Consistent feed flow ensures that each chamber receives an equal volume of slurry, which is critical for maintaining uniform cake thickness and quality. The ability to fine-tune the flow rate also allows for adjustments based on the specific characteristics of the feed material.

Automatic Plate Shifter: The automatic plate shifter is a key feature in some Quick Opening Filter Press models, facilitating the efficient handling of filter plates. This mechanism allows for the simultaneous and uniform opening of multiple plates, which is essential for consistent cake discharge. The automatic plate shifter reduces the need for manual intervention and minimizes the risk of mechanical issues or inconsistencies during the cake removal process. By ensuring that all plates open and close uniformly, the shifter helps maintain the integrity of the filter cakes and supports a smooth, uninterrupted filtration cycle.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt