Industry News

Home / News / Industry News / How can pharmaceutical preparation equipment improve the accuracy of chemical dosage in industrial applications?

Home / News / Industry News / How can pharmaceutical preparation equipment improve the accuracy of chemical dosage in industrial applications? How can pharmaceutical preparation equipment improve the accuracy of chemical dosage in industrial applications?

2024.12.30

2024.12.30

Industry News

Industry News

1. Precision metering system

The precision metering system is one of the core functions of drug production equipment. It can ensure that the raw materials are accurately weighed and proportioned during the production process. In industrial production, any tiny weighing may cause the quality of the drug to be unstable. Modern drug preparation equipment usually uses advanced technologies such as electronic scales, mass flow meters, and load sensors to achieve load dosage control. The electronic scale monitors the sensor radiator raw materials in real time at the micron level to ensure that the addition amount is always kept at the default value. The mass flow meter can accurately measure the flow rate of liquids and gases, adjust its flow in real time, and ensure that the input amount of each batch of raw materials is consistent with the formula requirements. These metering systems not only have the accuracy of measurement, but also greatly reduce the deviation of human operation, thereby ensuring the consistency and stability of drug preparation.

2. Automated control and feedback system

The automated control and feedback system in Pharmaceutical Preparation Device plays an important role in improving the accuracy of chemical measurement. The automated control system can monitor various key real-time parameters in the production process, such as temperature, pressure, flow, viscosity, pH value, etc. by integrating advanced sensors, computer control technology and data acquisition systems. These parameters have a direct impact on the chemical reactions in the drug preparation process. Any slight deviation may lead to inaccurate dosage, which in turn affects the quality of the drug. The automated control system can automatically adjust various parameters according to real-time data through the preset process flow to ensure the accurate progress of the drug preparation process. For example, when the temperature or pressure exceeds the preset range, the system will automatically adjust by controlling the valve or heating system to ensure that at the same time, the feedback system can continuously adjust the process and correct possible deviations in real time to ensure the accuracy of dosage control.

3. Efficient mixing and distribution

In the process of preparing drugs, uniform mixing of raw materials is the key to ensuring the accuracy of chemical measurement. Even if the amount of raw materials added is accurate, if the mixing is uneven, the final drug product may have uneven component concentration. Modern drug preparation equipment is equipped with efficient mixing and stirring devices to achieve uniform distribution of raw materials through precise stirring systems. These devices often use high-shear mixing technology, spiral double-paddle mixing technology, etc. These technologies can vigorously stir and mix raw materials in a short time, and fully blend raw materials in different forms such as solids, liquids or gases. High shear mixing technology can especially break up the aggregation of raw material particles through high-speed rotation, so that they are quickly and evenly dispersed in the solution, thereby ensuring the uniformity of the ingredients. For raw materials with higher viscosity, the equipment is also equipped with a special agitator and heating system, which makes it difficult for the raw materials to agglomerate during the mixing process, avoiding the problem of uneven mixing.

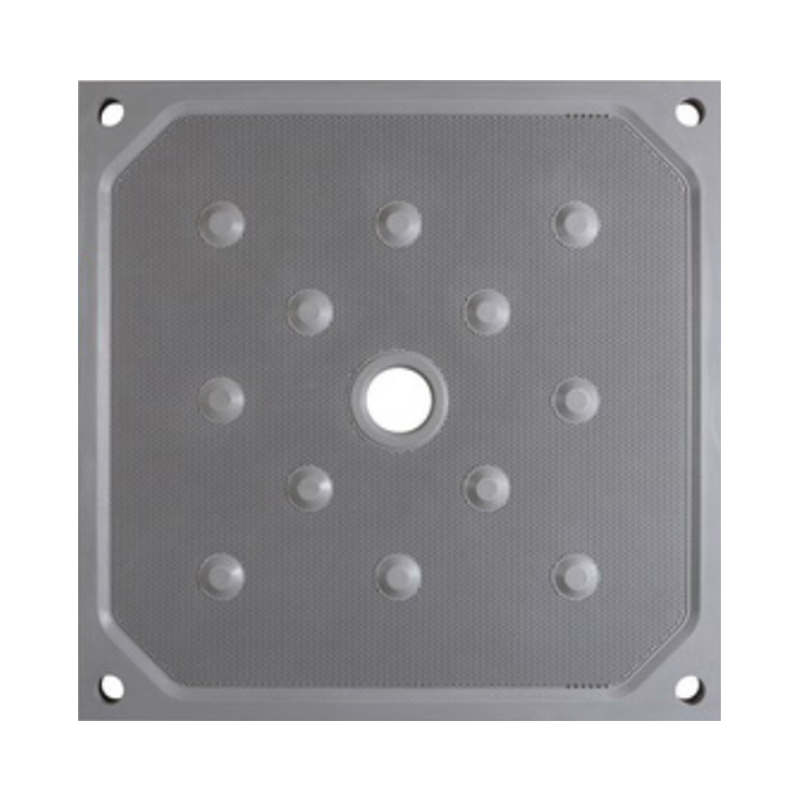

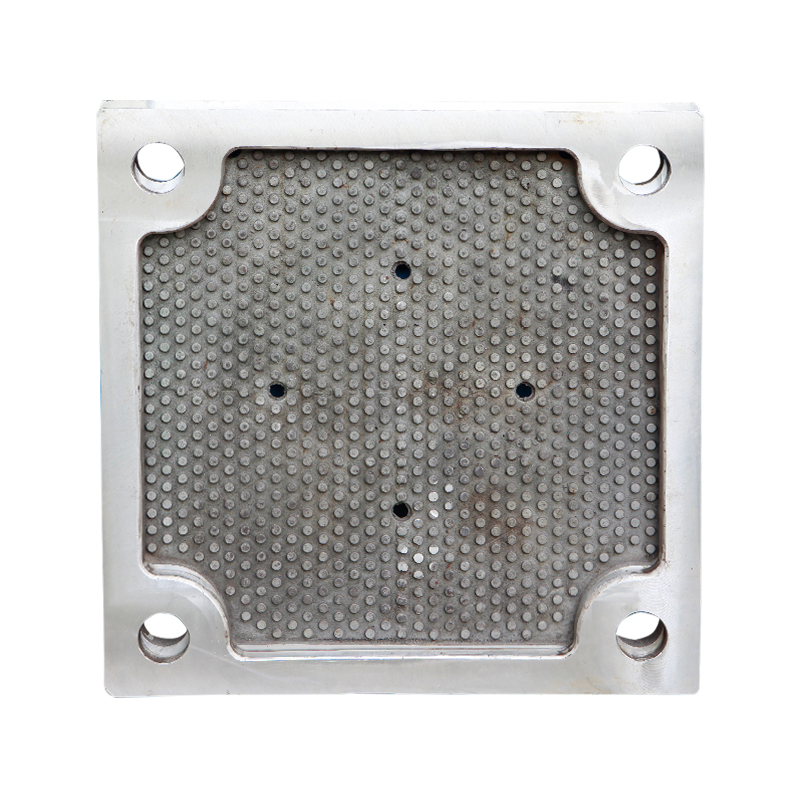

Recommended Products

Contact Information

No. 1, Sudong Road, Guxi Town, Taixing, Jiangsu, China

No. 1, Sudong Road, Guxi Town, Taixing, Jiangsu, China +86-15720778188

+86-15720778188 +86-523-87791016

+86-523-87791016 +86-523-87797781

+86-523-87797781 jssdylj@gmail.com

jssdylj@gmail.com

Quick Links

Mobile

Are You Ready To Cooperate With Us

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt