How does the material of filter press cloth affect its performance in various industries?

2024.12.16

2024.12.16

Industry News

Industry News

1. Filtration Efficiency and Particle Retention

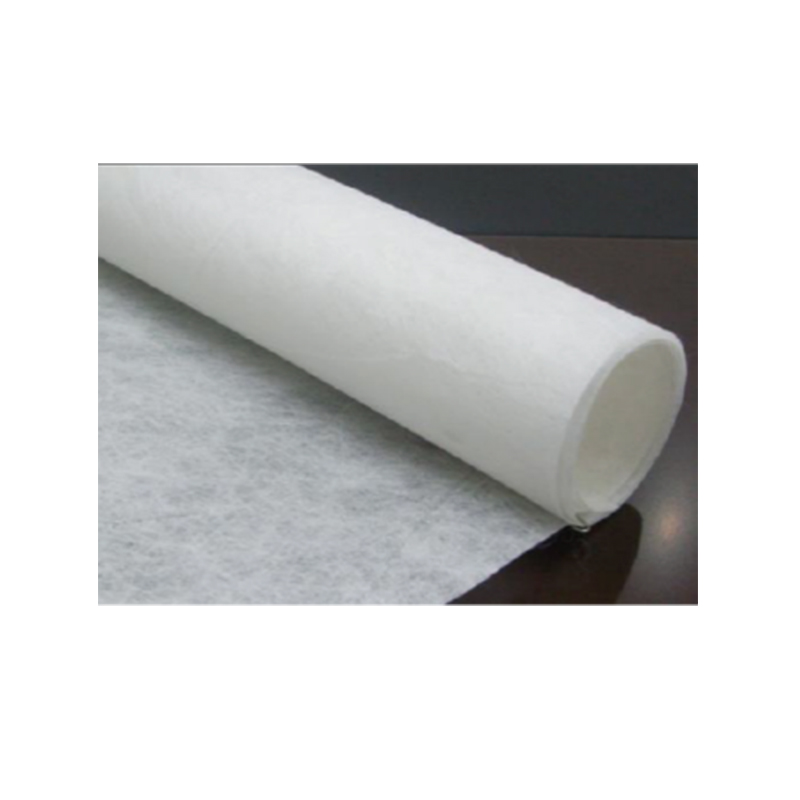

The material of the filter press cloth is one of the most significant factors that influence its filtration efficiency. The ability of the cloth to effectively trap solid particles while allowing the liquid to pass through depends on both the weave and the material properties. For example, polypropylene (PP) filter cloths are widely used in applications where moderate filtration efficiency is sufficient. These materials have a pore size that can effectively capture fine to medium-sized particles, which makes them ideal for industries like mining and wastewater treatment, where suspended solids need to be filtered from liquids. Their performance in capturing particles is influenced by the weave structure, which can vary from plain weave to twill weave.

On the other hand, nylon filter cloths offer superior precision in particle retention due to the material's smooth surface and higher tensile strength. This makes nylon cloths an excellent choice for applications requiring high filtering precision and tight particle retention, such as in the food and beverage and pharmaceutical industries. Here, the materials being filtered need to be free from even the smallest particles to ensure product quality and safety. Polyester (PET) also offers a fine balance between particle retention and flow rate, making it suitable for medium to high filtration accuracy in industries such as paper manufacturing or automotive where medium-sized particles need to be effectively captured.

2. Chemical Resistance

The ability of the filter press cloth to resist chemical degradation is paramount, especially in industries that deal with aggressive chemicals or solvents. Polypropylene is highly favored in industries where the process fluids are acidic or alkaline. Its strong resistance to a wide range of chemical substances, including strong acids and bases, makes it suitable for industrial applications like chemical processing, mining, and water treatment, where chemicals such as sulfuric acid or sodium hydroxide are frequently handled. The inherent chemical resistance ensures that the filter cloth does not degrade or lose its performance, maintaining filtration efficiency over time.

Nylon is particularly known for its ability to resist organic solvents, oils, and grease, which is why it is often used in the petrochemical and automotive industries, where fuel and oil are processed. The material’s resistance to oil-based chemicals ensures that it will not deteriorate when exposed to such substances, making it highly reliable in these industries. Polyester, with its strong resistance to acids and certain solvents, is frequently chosen for applications in the pharmaceutical and food industries, where chemical exposure is controlled but still present. The selection of material based on chemical resistance ensures that filter cloths can operate effectively in specific industrial environments without compromising the filtration process.

3. Temperature Resistance

Temperature plays a significant role in determining the longevity and performance of filter press cloths. Materials like nylon and polyester have high-temperature tolerance, making them suitable for use in demanding environments where temperatures may exceed the normal operating range for standard filtration materials. For example, nylon has a melting point of around 250°C, which allows it to operate efficiently at high temperatures without losing its strength or shape. This feature makes it ideal for automotive and electronics manufacturing, where high temperatures during processes like soldering or assembly are common. Polyester also has excellent heat resistance, typically allowing for stable operation in temperatures up to 150°C, which makes it ideal for industries like paper production or pharmaceutical manufacturing, where hot chemicals or steam might be used during filtration.

Polypropylene is more temperature-sensitive, with a typical operational temperature limit of 90°C. While it is still suitable for many industrial applications, polypropylene filter cloths are typically not used in environments where temperatures are expected to exceed this threshold. This is why polypropylene is commonly used in water treatment and food processing industries, where filtration temperatures are typically lower, and the material’s performance is more than adequate. The appropriate temperature resistance of the filter cloth is critical to ensure consistent performance, prevent material failure, and extend the life of the equipment used in filtration processes.

4. Durability and Wear Resistance

Durability is a key factor in the selection of filter press cloth, particularly when considering applications that involve heavy-duty or high-frequency filtering. Materials like polyester are known for their exceptional durability and wear resistance. Polyester fibers maintain their strength even under constant mechanical stress, such as during high-pressure filtration processes or when dealing with abrasive particles. The superior abrasion resistance of polyester makes it ideal for applications like mining and construction, where the filter cloth may come into contact with rough, abrasive substances. The material’s resistance to wear helps minimize the need for frequent replacements, which ultimately reduces operational costs and downtime.

Nylon offers outstanding durability and wear resistance, particularly in situations where the filter cloth needs to withstand not only mechanical wear but also the stresses of chemical exposure. It is ideal for automotive, petrochemical, and pharmaceutical industries, where both mechanical and chemical durability are necessary to ensure that the filter cloth can endure harsh operating conditions without premature failure. The rugged nature of nylon filter cloths contributes to their longevity, reducing the frequency of maintenance and ensuring consistent performance in demanding environments. Polypropylene, while not as durable as nylon or polyester, still offers adequate durability for lighter industrial applications, making it suitable for water treatment and food processing, where the wear conditions are less severe.

5. Cost Considerations

Cost is an essential consideration when selecting the material for filter press cloths, especially when dealing with large-scale filtration applications. While materials like nylon and polyester may come with higher upfront costs, their superior durability, strength, and performance often make them more cost-effective in the long run due to lower maintenance and longer service life. In industries such as petrochemical processing or pharmaceutical manufacturing, where downtime or inefficiency is costly, investing in high-performance filter cloths can significantly enhance operational efficiency and reduce replacement costs over time.

On the other hand, polypropylene is a more budget-friendly option and is often selected for applications where filtration demands are moderate, and the material will not be subjected to extreme temperatures or harsh chemicals. Industries such as water treatment, food processing, and general chemical filtration often choose polypropylene for its affordability, as the material offers adequate performance for many standard filtration needs without the higher cost associated with nylon or polyester. The choice of material often comes down to a balance between cost and performance, where companies must consider the specific demands of their filtration processes and the potential for longer-term savings in maintenance, efficiency, and equipment lifespan.

English

English Español

Español हिंदी

हिंदी Tiếng Việt

Tiếng Việt